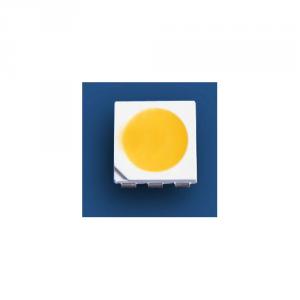

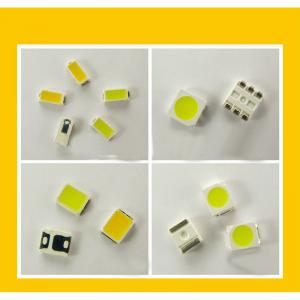

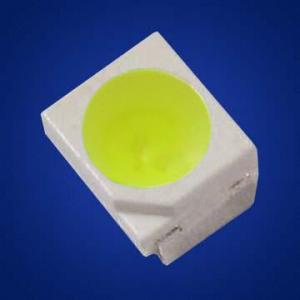

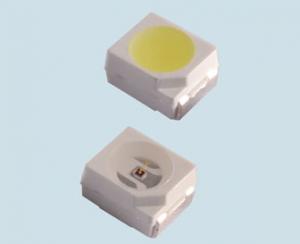

Epistar Chip Diode 3.0-3.4V 60Ma 24-26lm 0.2W 2835 SMD LED Specifications

- Loading Port:

- Shenzhen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 4000 Pcs pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Epistar chip diode 3.0-3.4V 60mA 24-26lm 0.2W 2835 smd led specifications

*Samples can be delivered to you for testing firstly and all samples are FREE .

*Delivery Detail: 4-7 working days delivery after received full payment

Quality Control:

Our company had obtained the ISO9001:2000 quality management certification and our products had gain CE and RoHS certifications.Meanwhile, the company had congregated a batch of excellent people from the LED industry which our General Manager, Engineers, Directors, and our manager of quality department have been working in LED industry around 10 years.All these are our solid basis of our company quality control.

Our Services:

1.Any your inquiry will be responsed within 48hours

2.Competitive price help you have better market

3.OEM requests are greatly welcome

4.Supply accessories, such as:Resistor, Solder Paste, PCB, etc.

5.Free Samples about LED components.Express Fee would be paid by receiver

Office Time:

1.8:30 a.M to 6:00 p.M (GMT+8) of Monday to Friday

2.Our office is closed on Chinese Public holidays

3. LC

Payment methods:

1.T/T

We are insisting on high quality is our responsibility, high quality is only condition for our eternal development, to provide clients our the best products, technical support and services.

Delivery:

Shipping Service | Estimated Delivery Time |

DHL | 2-8 business days |

FedEx | 3-8 business days |

TNT | 2-10 business days |

UPS | 1-7 business days |

EMS | 6-14 business days |

ePacket | 7-12 business days |

China Post Air Mail | 7-15 business days |

China Post SAL | 14-30 business days |

Air freight | 3-10 business days |

By Sea | 30-40 business days |

1. 3-5 business days for Sample Orders; 7-30 business days for Bulk Orders for Bulk Orders.

2. "Business days" means Monday-Friday, excluding holidays.

3. DHL and UPS cannot ship to military or P.O. boxes address

4. The Shipping Service above is for reference only, for any other questions, please feel free to contact us.

- Q: 0603,0805,1206,3020,3528,5050,355 what is the current and voltage of these patch LED? Please give advice!

- SMD LED specification:(1) metal stent type: 0402, 0603, 0805, 1206, 3mm, 5mm, 6mm, 8mm, 10mm and so on.(2) metal support (commonly known as small butterfly) type: 2mm, 3mm and so on.(3) TOP LED (white shell) type: 1208 (30*20), 1311 (35*28), 1312 (35*32), 2220 (55*50) and so on(4) side light LED:0905 (22*12), 1105 (28*12) 1605 (40*14) and so on.

- Q: LED light SMD LED package in what form, trouble you under the guidance of...

- Draw your own line, mm is replaced by mil on the line, with vernier caliper measurement, or know the model, count the number of mil. For example, 5050 is a close square with a width of 5.0mm*5.0mmInline LED (such as straw hat lights, 5mm), piranha LED, surface mount LEDSinglechip collection from hardware to software chm

- Q: What, in what way do I shunt the LED?

- In series, the voltage is 20 times the rated voltage, in parallel, the voltage is rated voltage, but in tandem, a LED is broken, it is not bright, so it is recommended not to use it.

- Q: Patch LED beads can be bought in what place?

- Many LED packaging plants do patch LED, you can find the relevant manufacturers to contact, or go to the local electronic components market according to your needs

- Q: Patch LED market conditions

- Conventional monochrome SMD LED package sizes are 1206 (3215), 1004 (2510), 0805 (2012) and 0603 (1608). Chinese manufacturers can provide a minimum size of 0603, the thickness of only 0.3 mm. A smaller LED of 0402 (1005) is still in trial manufacture

- Q: What is the difference in performance between the LED plug-in and the LED patch?

- No difference, because the core of the two is the same, are diode PN junction, but no packaging, the production process is a little different

- Q: What does "1210" mean in patch LED?

- 1210 refers to the lamp specifications.LED common lamp specifications and parameters of patch0603, 0805, 1210, 3528, 5050 refers to the LED lamp belt, often used in light-emitting components ----LED size (English / Metric) name, for example, 0603 refers to the length of 0.06 inches, width of 0.03 inches. But note that the 3528 and 5050 units are metric

- Q: The ten patch LED lights are connected in parallel. The rated power is 5 watts. How much voltage do you need?

- The ten patch LED lamps are connected in parallel with rated power of 5 watts and voltage 3.3V.

- Q: How do led patches measure good or bad?

- Use the two stage tube test of the multimeter, the red pen is connected, and the black pen is negative. If there is a bee, the sound is bad, and if the light is bright, it is good

- Q: SMD LED lamp working voltage?

- Single chip of 1 watts, more than a lot, different colors, the voltage will be different. White is usually 3.0-3.6V.* in addition to their working voltage, working current is more important parameters, once the flow, it will burn out.The LED lamp. With chips is variety, many tricks, they can be connected in series and parallel. The voltage is divided into high voltage, low voltage and medium voltage

Send your message to us

Epistar Chip Diode 3.0-3.4V 60Ma 24-26lm 0.2W 2835 SMD LED Specifications

- Loading Port:

- Shenzhen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 4000 Pcs pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords