Embossed Polycarbonate Solid PC Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

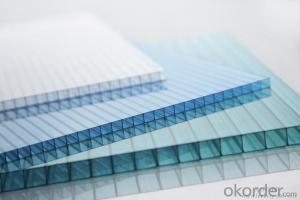

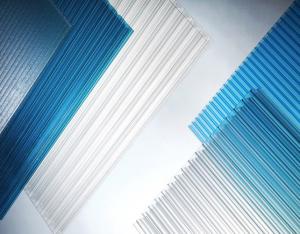

Type: Sun Sheets & PC Embossed Sheets

Place of Origin: Zhejiang, China (Mainland)

Model Number: PE02

material: Polycarbonate

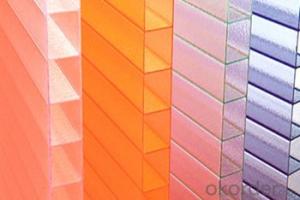

color: clear, green, blue , light blue , brown , opal , red , yellow

certification: ISO9001:2008, ROHS , SGS

Packaging & Delivery

Packaging Details: PE film protection on both side, fumigation pallet package for all solid sheet

Delivery Detail: 7-25days after confirm the prepayment

Specifications

1.10 years warranty

2.50 micro UV protection both side

3.thickness by customers

4.Great impact strength

5.Beautiful color

Embossed POLYCARBONATE PC SOLID SHEET

1. ISO9001:2008 proved

2. Size can be customized

3. Good impact resistance

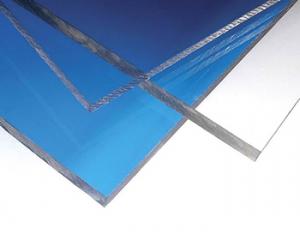

PC embossed solid sheet is made by polycarbonate resin.

On the basis of common pc solid sheets technique and improvements of molds and production, the optical properties are changed as the surface structure of the product varies. Single side of pc embossed sheet contains UV protective layer, therefore, its mechanical properties, fire retardation, applicable temperature and chemical properties are consistent with common solid sheet. By changing the physical shape of the surface,

when light gets through the embossed sheet, it produces light scattering to get a vague hazy effect. Currently, pc embossed sheet is very ideal architecture material.

Features of Product

1. Light transmission Polycarbonate sheet has very good light transmission. Prolonged sun exposure of UV coated plate does not produce yellowing, fogging and poor light. The loss of light transmittance is 6% for embossed sheet and 15%-20% for PVC after ten years.

As light through its convex particles produces light scattering, it has good optical effect. For more information about light transmission, please feel free to contact us.

2. Anti-UV & Heat Insulation UV protective layer, 98% UV absorbed.

3. Light weight, high impact strength,excellent physical and mechanical properties and well bending performance The mechanical properties of pc embossed sheet are consistent with pc solid sheet. Maintaining good impact resistance for a long time in a wide temperature range (-40°C-120°C).

4. Fire retardation Embossed Polycarbonate sheet meets the national standard GB8624-1997 and ranks at B1 retardant material level. In the process of combustion, the sheet does not produce any smoke and toxic gases, and automatically turns off from the fire. It has good fire retardant properties.

5.Wide-ranging application, good weather-resistance Maintaining the stability of mechanical properties between -40°Cto +100°C, the sheet does not occur the cold crisp above -100°Cand without softening below 145°C. Small size change from 100°Cto -40°C, the rate of change is ≤ 0.3%. 2000 hours of artificial aging test towards the sheet, the yellowing degree was grade 2, and the transmission rate was decreased by 0.6%.

6. Soundproof The sheet can effectively reduce the noise, and is the best choice for soundproof.

7. Convenience for transportation and construction Light weight, standard size, convenient transportation & construction, easy cutting and punching,

cold bent and good processing performance.

8. Condensation inhibition Under normal circumstances, when the outdoor temperature is 0°C, room temperature is 23°Cand the indoor relative humidity is below 80%, the inner surface of the material does not frost.

9. Chemical resistance Polycarbonate Sheet can resist various kinds of harmful corrosive materials, such as organic acid, inorganic acid, vegetable oil, neutral salt solution, aliphatic hydrocarbon and alcohol, etc.

Storage, transportation and usage

Prohibit contact with wet cement surface and acid, alkaline material surfaces.

Prohibit contact with organic solvents and glue, paint composed thereof.

Keep the frame clean and the surface of rabbet groove flat.

Dust and dirt of the sheet are generally wiped by soft cloth or sponge with mild detergent first and then washed by water thoroughly.

Choose the right thickness, allow flexure radius.

If use self –drilling screws for fixing, the hole must be pre-drilled, and the aperture should be 1.5 times larger than the diameter of the screw.

Do not tighten the screw strongly, otherwise stress will arise, and crack on the sheet surface will appear.

Remain space for expanding, pay attention to inserting depth.

Expanding Value = linear expansion coefficient × length × the maximum temperature variation (linear expansion coefficient of pc sheet is 7×10-5mm/mm/°C).

Use neutral glass cement and right gasket. Never use gasket of PVC material. Use electrical tools (tungsten carbide saw) to cut, stabilize PC sheet to prevent their vibration.

Don't peel off protective film when cutting. In case that marks have to be made before cutting, try to mark on protective film.

If the marks must be made directly on PC sheets, use wax crayon instead of any sharp tool to mark.

Never peel off protective films until installation is completed. It is suggested that smooth side is installed towards sun in order to realize the effect of the UV protective layer.

Application

Commercial Building Lighting

Industrial architecture lighting

Stadium roof and indoor play area

Transportation infrastructure Residential architecture lighting

Exterior–protected construction and curtain wall

Bathroom and swimming pool

- Q: What is the difference between sun panels and plexiglass?

- Sun panels are PC polycarbonate materials, sun PC board is usually double-layer structure, the thickness of more than 10mm for the multi-layer and shaped structure. Transparency reached 89%. ??? Cold and heat: -40 ℃ ~ 120 ℃ between the sun plate does not produce deformation. ??? Its own ignition is 580 ℃, self-extinguishing from the fire, burning will not produce toxic gases, will not contribute to the spread of fire.

- Q: Which friends know how to remove the plastic film on the sun?

- Generally can be removed by hand But should pay attention not directly under the sun exposure, or may lead to thin film too thin, not easy to tear. After the installation of sun panels, should immediately tear off the film

- Q: How to correctly identify the quality of pc sunshine board and pc durability plate method

- Look at the product surface. Protective film paste flat, no shedding. Indicating that manufacturers of product production, sales attention. Of course, some bag companies, small companies pay attention to packaging, because this customer is like moon cakes, in the use, the best choice for the strength of the old company

- Q: PC board greenhouses pc board generally use thick? What is the price? What about the current market price? Is the sun board a PC board?

- In addition, most manufacturers will use recycled materials, basically low-cost-based, no guarantee. I suggest you choose, these manufacturers do not ask, boring, save that money is not enough after the repair it So the election board when a principle: want to do the performance of the project, with a good Bayer plate, basically no trouble; want to earn more money or low bid winning project, with the back of the board, anyway, never mind.

- Q: To build a sunshine shed, with Cortron PC patience board or good sun board?

- Nai Liban board a little better, but the cost of the durability plate is too high, the sun will have a lot of concessions, the general use of four sun panels, structural stability, high quality performance. Pc sun panels for the production of polycarbonate as the main raw material. At present the international widely adopted a high-intensity, translucent, sound insulation, energy-saving new high-quality decorative materials. Sunshine plate in the mid-80s into the building materials, decorative materials market. Than the laminated glass, folder glass, tempered glass, insulating glass more light, weather, super, flame retardant, sound insulation of the excellent performance, due to the special quality of the sun plate. Get the architectural design, decoration works, environmental engineering, advertising industry generally recognized.

- Q: Pc sun panels and frp lighting board what are the two differences

- 1. Material is a PC, one is FRP commonly known as glass fiber high performance UV resin; 2.PC is not resistant to corrosion, FRP is a good anti-corrosion performance; 3.PC sun board is hollow board, light transmission is better, FRP is usually a solid plate, usually semi-translucent state; 4. High-quality PC sunshine board surface has UV coating, anti-ultraviolet, anti-yellowing, such as Cortron sunshine board, and high-quality FRP surface is covered with thin film, such as red wave FRP lighting tile. 5.PC warranty period up to 10 years or so, FRP warranty up to 25 years;

- Q: What is the difference between PC stamina and PC sunboard?

- The easiest way to do this is to compare one or more of the sun panels with the stamina. The difference is obvious, from the structural distinction, PC sun panels have a single layer, double, and even multi-layer and is hollow. PC Nai Liban is single layer solid. From the weight of the distinction, because the sun is hollow, the material is relatively small, so the same thickness and area of the endurance plate much heavier than the sun.

- Q: Can the stencils be made in the bathroom?

- PC particle board characteristics 1, the surface of the plate can reflect the direct light on the plate of direct exposure, after this treatment can reduce the sunlight penetration. 2, the surface of the board can increase the surface area, while increasing the heat, can extend the service life of the plate. 3, the surface of the plate per square meter distribution of 15,000-18000 pieces of anti-diamond-type particles, reflection, refraction effect can enhance the blocking capacity.

- Q: Lighting board and sunshine board which is good?

- This can not say which is better, can only say which product is suitable for you to use, the general enterprise plant lighting with lighting panels, and some flower room on the temperature requirements of the more stringent must use sun panels and shade net supporting the use.

- Q: Can the sun board cover the bedroom?

- Sun panels can cover the bedroom, the sun board mainly by the PC / PET / PMMA / PP material production. English is sunlight, referred to as hollow board, pc sun panels to polycarbonate as the main raw material manufacturing. Sunshine board in the mid-80s into the building materials quickly.

Send your message to us

Embossed Polycarbonate Solid PC Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords