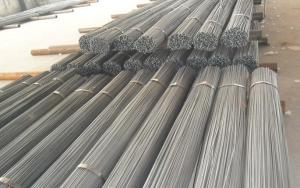

Eleven mm Cold Rolled Steel Rebars with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Eleven mm Cold Rolled Steel Rebars with High Quality:

Name | Eleven mm Cold Rolled Steel Rebars with High Quality | |

Diameter | 5mm, 5.5mm, 6mm, 6.5mm, 7mm, 8mm, 9mm, 10mm, 11mm, 12mm, | |

Length | 6M, 9M, 12M or as required | |

Price | Keep lower operating costs so as to offer competitive price for our clients | |

Label | to be specified by customer, generally, each bundle has 1-2 labels | |

Application | Building, construction | |

Invoicing | Actual or Theoretical Weight Basis as buyer’s request. | |

Theoretical weight and section area of each diameter of Eleven mm Cold Rolled Steel Rebars with High Quality as below for your information:

Diameter(mm) | Section area (mm²) | Mass(kg/m) | Weight of 12m (kg) | Pcs/ton |

11 | 95.0 | 0.746 | 8.952 | 111.71 |

Packaging & Delivery of Eleven mm Cold Rolled Steel Rebars with High Quality:

Packaging Detail: products are packed in bundle and then shipped by container or bulk vessel, deformed bar is usually naked strapping delivery, when storing, please pay attention to moisture proof. The performance of rust will produce adverse effect.

Each bundle weight: 2-3MT, or as required

Payment terms: TT payment in advance or Irrevocable LC at sight.

Trade terms :FOB, CFR, CIF

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The shipping date is dependent upon the quatity, how many sizes you want and the plan of production, but is typically 1 month to 2 month days from the beginning of production.

Images of Eleven mm Cold Rolled Steel Rebars with High Quality:

- Q: What are the different types of steel rebars used in foundation construction?

- There are several different types of steel rebars that are commonly used in foundation construction. These include: 1. Mild Steel Rebars: Also known as black bars, mild steel rebars are the most commonly used type of rebars in foundation construction. They have a low carbon content and are easy to work with. Mild steel rebars provide good tensile strength and are cost-effective. 2. High Yield Strength Rebars: These rebars have a higher carbon content and are heat-treated to increase their strength. They are commonly used in areas where extra strength is required, such as in high-rise buildings or in seismic zones. High yield strength rebars offer superior resistance to tensile and compressive forces. 3. Epoxy-Coated Rebars: Epoxy-coated rebars are coated with epoxy resin to protect them from corrosion. They are commonly used in areas where the foundation is exposed to moisture or chemicals, such as in marine or industrial environments. The epoxy coating acts as a barrier, preventing water and other corrosive substances from reaching the steel and causing it to rust. 4. Galvanized Rebars: Galvanized rebars are coated with a layer of zinc to protect them from corrosion. The zinc coating provides excellent resistance to moisture and chemicals, making galvanized rebars suitable for use in areas with high humidity or in contact with concrete that contains chloride ions. They are commonly used in coastal areas or in structures such as bridges and parking garages. 5. Stainless Steel Rebars: Stainless steel rebars are highly corrosion-resistant and are used in environments where other types of rebars may fail due to corrosion. They are commonly used in structures that are exposed to aggressive environments, such as in chemical plants or wastewater treatment facilities. Stainless steel rebars are also used in areas with a high risk of corrosion, such as in coastal or humid regions. Overall, the choice of steel rebars for foundation construction depends on factors such as the specific requirements of the project, the environmental conditions, and the level of corrosion resistance needed. It is important to select the appropriate type of rebar to ensure the longevity and strength of the foundation.

- Q: How are steel rebars made?

- Steel rebars, also known as reinforcing bars, are made through a process called hot rolling. First, steel billets are heated to extremely high temperatures and then passed through a series of rollers, which shapes them into long, cylindrical bars. These bars are then cooled and cut into desired lengths to form the steel rebars, which are widely used in construction to reinforce concrete structures and provide strength and durability.

- Q: What are the different types of surface finishes available for steel rebars?

- Some of the different types of surface finishes available for steel rebars include black or plain, epoxy-coated, galvanized, and stainless steel.

- Q: How do steel rebars affect the crack width in reinforced concrete?

- Steel rebars can help to control and limit crack width in reinforced concrete structures. The presence of rebars provides reinforcement and increases the tensile strength of the concrete. This enhanced strength helps to distribute and redistribute the stresses caused by loads, reducing the likelihood and width of cracks forming in the concrete. Additionally, the rebars act as a barrier, preventing cracks from propagating and limiting their width.

- Q: Can steel rebars be bent or shaped during construction?

- Yes, steel rebars can be bent or shaped during construction. They are commonly used in reinforced concrete structures and can be bent to fit the required design, shape, or structure.

- Q: How do steel rebars affect the constructability of projects in remote locations?

- Steel rebars can have a significant impact on the constructability of projects in remote locations. Due to their weight and bulkiness, transporting rebars to remote sites can be challenging and expensive. Additionally, the availability of rebars in remote areas may be limited, leading to delays in construction timelines. However, the presence of steel rebars is crucial for reinforcing concrete structures, ensuring their strength and durability. Therefore, careful planning and coordination are necessary to overcome logistical obstacles and ensure the successful implementation of projects in remote locations.

- Q: What specifications should be used for the three - step steel electroslag pressure welding electrode?

- The electrode (coveredelectrode), is the metal coating in the welding core (coating), uniform centripetal pressure applied to core. The core metal cored electrode, in order to ensure the quality and performance of the weld, there are strict rules on the contents of metal elements in the core, especially for harmful impurities (such as sulfur, phosphorus content, etc.) should be strictly restricted, better than the base metal. The electrode consists of two cores and coating composition. The different cores are also different. The core components directly affect the composition and properties of the weld metal, so the harmful elements in the welding core to as little as possible.

- Q: Can steel rebars be used in structures with high sulfate content in soil or water?

- Steel rebars should generally not be used in structures with high sulfate content in soil or water. Sulfates can react with the steel and cause it to corrode rapidly, leading to structural damage and potential failure. To mitigate this risk, alternative materials such as stainless steel or fiber-reinforced polymer rebars may be recommended for use in such environments.

- Q: Are there any alternative materials to steel rebars?

- Yes, there are alternative materials to steel rebars. Some examples include fiberglass, carbon fiber, and basalt rebar. These materials offer advantages such as higher strength-to-weight ratios, corrosion resistance, and better durability in certain environments. However, the selection of alternative materials depends on specific project requirements and cost considerations.

- Q: What is the impact of steel rebars on the overall sustainability of a structure?

- Steel rebars have a significant impact on the overall sustainability of a structure. By reinforcing concrete and improving its strength, steel rebars help to increase the lifespan of the structure, reducing the need for frequent repairs or replacements. This not only enhances the long-term durability of the building but also reduces the consumption of resources and energy required for construction. Additionally, steel rebars can be recycled, making them an environmentally friendly choice. Overall, the use of steel rebars in a structure enhances its sustainability by promoting longevity, reducing waste, and minimizing environmental impact.

Send your message to us

Eleven mm Cold Rolled Steel Rebars with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords