Electtic Resistance Welded steel Pipe ERW Oil Pipes Factory

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of Seamless Pipe ASTM A106/53:

Seamless pipe is formed by drawing a solid billet over a piercing rod to create the hollow shell. As the manufacturing process does not include any welding, seamless pipes are perceived to be stronger and more reliable. Historically seamless pipe was regarded as withstanding pressure better than other types, and was often more easily available than welded pipe.

carbon seamless steel pipes are widely used in gas, water and oil, transpotation;constructions;Bridge,highway,windows of model steel door; building materials;fences;heating facilities Fluid Pipe;conduit pipe,scaffolding pipe.etc.

Payment Terms: L/C D/A D/P T/T

Packing and shipment

Packaged in bundles,as per customers' requirements, it can also bepackagesd as beveled ends, typed marking, black painting, plastic caps protection,woven bags packing

For 20" container the max length is 5.8m; For 40" container the max length is 12m. other options are available based on customer requests. Please discuss when placing orders.

2、Main Features of the Seamless Pipe ASTM A106/53:

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Reasonable price

3、Seamless Pipe ASTM A106/53 Specification:

| Thickness: | 1.5 - 14 mm | Section Shape: | Round | Outer Diameter: | 21 - 219 mm |

Place of Origin: | Tianjin China (Mainland) | Secondary Or Not: | Non-secondary | Application: | Structure Pipe |

| Technique: | Cold Rolled | Certification: | ISO | Surface Treatment: | oiled |

Special Pipe: | EMT Pipe | Alloy Or Not: | Non-alloy | Wall thickness: | thin wall pipe |

| Grade: | Q195,Q195-Q345 | Standard: | BS ,JIS G3101,DIN 2444,BS,JIS,DIN,API 5L |

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of Seamless Pipe ASTM A106/53:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

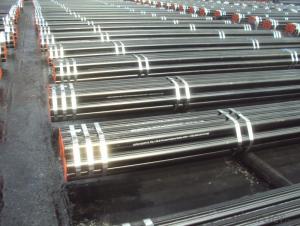

6、Seamless Pipe ASTM A106/53 Images:

- Q: How are steel pipes recycled at the end of their life cycle?

- Steel pipes are typically recycled at the end of their life cycle by first being collected and sorted at recycling facilities. They are then cleaned and processed to remove any contaminants. The pipes are further broken down into smaller pieces and melted in a furnace. Once the molten steel is formed, it can be used to create new steel products, such as pipes or other construction materials. This recycling process helps reduce the demand for new steel production and conserves valuable resources.

- Q: What is the typical length of a steel pipe?

- The typical length of a steel pipe can vary depending on its purpose and application. However, standard lengths for steel pipes often range from 20 feet to 40 feet.

- Q: What is the maximum length of steel pipes available?

- The maximum length of steel pipes available can vary depending on the manufacturer and the specific requirements. However, standard lengths for steel pipes typically range from 18 to 24 feet.

- Q: How are steel pipes measured?

- Steel pipes are typically measured by their outer diameter (OD) and wall thickness. The OD is measured using a caliper or tape measure, while the wall thickness is determined using specialized tools like ultrasonic gauges or micrometers. These measurements are crucial for determining the pipe's size, strength, and suitability for various applications.

- Q: Seamless steel tube with the tube with what is the difference?

- Seamed tube can withstand the maximum pressure is generally less than 20 kg, which is the most secure use. It is generally used in water, gas, compressed air and other low-pressure fluid;

- Q: Can steel pipes be used for culvert applications?

- Yes, steel pipes can be used for culvert applications. Steel pipes are commonly used for culverts due to their strength, durability, and resistance to corrosion. They are capable of handling heavy loads and can withstand harsh environmental conditions, making them suitable for various culvert applications such as road and railway crossings, drainage systems, and stormwater management.

- Q: What is the role of steel pipe manufacturers in sustainable development?

- The role of steel pipe manufacturers in sustainable development is to promote environmental responsibility and resource efficiency throughout the production process. They play a crucial role in reducing carbon emissions by adopting cleaner technologies, optimizing energy consumption, and implementing waste management strategies. Additionally, steel pipe manufacturers can contribute to sustainable development by prioritizing the use of recycled materials, supporting recycling initiatives, and ensuring their products have a long lifespan to minimize waste generation. By embracing sustainable practices, steel pipe manufacturers can help create a more sustainable future for the construction and infrastructure industries.

- Q: Can steel pipes be used for conveying solid materials?

- Yes, steel pipes can be used for conveying solid materials. Steel pipes are commonly used in industries such as construction, oil and gas, and mining to transport solid materials such as ores, coal, grains, and various other solid substances. The durability and strength of steel make it suitable for handling the weight and pressure of solid materials during transportation.

- Q: What are the different grades of steel used in manufacturing pipes?

- There are several grades of steel used in manufacturing pipes, including carbon steel, alloy steel, stainless steel, and duplex steel. Each grade has distinct properties and characteristics that make it suitable for different applications and environments.

- Q: How do steel pipes handle chemical substances?

- Steel pipes are highly resistant to chemical substances due to their inherent strength and durability. They can effectively handle a wide range of chemical substances without corroding or degrading. Additionally, steel pipes can be further protected by coatings or linings to enhance their resistance to specific chemicals.

Send your message to us

Electtic Resistance Welded steel Pipe ERW Oil Pipes Factory

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords