Electronical Hot Rolled Galvanized Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Electronical Hot Rolled Galvanized Steel

1、QUALITY

GB/T343 and other standards.

2、 ZINC COATING

GB/T15393 and other standards.

3、RAW MATERIAL

A、WIRE ROD: 1006、1008、1018、Q195

ZINC WITH 99.995% purity.

4、TENSILE STRENGTH RANGE

(mm)size | (mpa)tensile strength |

0.24—1.60 | 290--550 |

1.61—5.00 | 400--1200 |

5、APPLICATION

Detonator lead、artware、 redrawing, toy, etc.

6、Packing

(mm) size | Coil size | Spool packing | big coil packing | |

(mm)ID | (mm)OD | |||

0.24—0.45 | 8 | 1—100㎏ | ||

0.46—0.60 | 8、12 | 1—100㎏ | ||

0.61—1.60 | 12、14、16 | 1—100㎏ | 250-400 | 400-770 |

1.61—5.00 | 450 | 800 | ||

7、 ZINC COATING

mm SIZE | (g/㎡)Min. zinc coating | |||||||

A | AB | B | C | D | E | F | ||

A1 | B2 | |||||||

≤0.25 | 18 | 15 | 12 | 5 | ||||

〉0.25-0.40 | 25 | 20 | 12 | 5 | ||||

〉0.40-0.50 | 25 | 20 | 15 | 8 | ||||

〉0.50-0.60 | 25 | 20 | 15 | 8 | ||||

〉0.60-0.80 | 20 | 15 | 10 | |||||

〉0.80-1.20 | 25 | 18 | 10 | |||||

〉1.20-1.60 | 25 | 18 | 12 | |||||

〉1.60-1.80 | 100 | 70 | 40 | 30 | 20 | |||

〉1.80-2.20 | 105 | 80 | 50 | 40 | 20 | |||

〉2.20-2.50 | 110 | 80 | 55 | 40 | 25 | |||

〉2.50-3.00 | 120 | 90 | 70 | 45 | 25 | |||

〉3.00-4.00 | 100 | 85 | 60 | 30 | ||||

〉4.00-5.00 | 110 | 95 | 70 | 40 | ||||

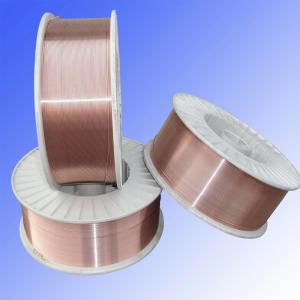

Picture

- Q: How is steel used in the production of tools and hardware?

- Steel is commonly used in the production of tools and hardware due to its strength, durability, and versatility. It can be forged, shaped, and tempered to create various types of tools such as wrenches, hammers, screwdrivers, and saw blades. Steel's hardness allows it to withstand heavy use and resist wear and tear, making it ideal for tools that require high strength and toughness. Additionally, steel can be easily machined and sharpened, enabling the production of precise cutting edges and intricate designs, further enhancing its utility in the manufacturing of tools and hardware.

- Q: What are the different types of steel bars and their uses?

- There are several types of steel bars, each with its own unique properties and uses. Some common types include carbon steel bars, alloy steel bars, stainless steel bars, and tool steel bars. Carbon steel bars are widely used in construction and general manufacturing due to their strength and affordability. Alloy steel bars are known for their exceptional strength and durability, making them suitable for applications requiring high strength and resistance to wear and tear. Stainless steel bars are corrosion-resistant and commonly used in food processing, architectural structures, and medical equipment. Tool steel bars are specifically designed for toolmaking, offering high hardness, toughness, and heat resistance. Overall, the different types of steel bars cater to a wide range of industries and applications.

- Q: What are the different types of steel products used in the manufacturing of toys and games?

- There are various types of steel products used in the manufacturing of toys and games, including steel wires, steel sheets, and steel rods. These materials are commonly used to create structural components, such as frames or supports, as well as smaller parts like connectors or joints. The steel used in toy and game manufacturing is often chosen for its strength, durability, and ability to withstand wear and tear.

- Q: How are steel products used in the manufacturing of consumer goods?

- Steel products are used in the manufacturing of consumer goods in various ways, such as in the production of appliances like refrigerators, washing machines, and ovens, as well as in the construction of automobiles, bicycles, and furniture. Steel's durability, strength, and versatility make it an ideal material for these applications, providing stability, safety, and longevity to the final products.

- Q: How are steel products used in the construction of residential buildings and housing complexes?

- Steel products are extensively used in the construction of residential buildings and housing complexes due to their strength, durability, and versatility. They are commonly employed in the structural framework, such as beams, columns, and trusses, providing a sturdy and stable support system. Steel is also used for reinforcing concrete, increasing the strength and resistance of the building against various forces. Additionally, steel is utilized in the construction of roofing systems, wall panels, stairs, and balconies, offering aesthetic appeal and long-lasting performance. Overall, steel products play a crucial role in ensuring the safety, stability, and longevity of residential buildings and housing complexes.

- Q: How is steel used in the production of storage tanks?

- Steel is commonly used in the production of storage tanks due to its durability, strength, and resistance to corrosion. It provides a reliable and long-lasting storage solution for various substances, including liquids and gases, as it can withstand high pressures and harsh environmental conditions. The steel is typically formed and welded to create the desired tank shape, and its properties ensure the containment and safe storage of materials over an extended period of time.

- Q: How is steel used in the construction of wastewater treatment plants?

- Steel is extensively used in the construction of wastewater treatment plants due to its durability, strength, and corrosion resistance. It is used for various applications such as structural supports, tanks, pipes, and equipment. The steel structures can withstand the harsh environment and chemicals found in wastewater, ensuring the longevity and reliability of the treatment plant.

- Q: How is steel pipe welded for structural applications?

- Steel pipe is typically welded for structural applications using one of several methods, such as arc welding, resistance welding, or oxyfuel welding. The specific method used depends on factors such as the pipe diameter, wall thickness, and the desired strength and quality of the weld. Welding processes like electric arc welding involve the use of an electric current to generate intense heat, melting the edges of the pipe together. Welding techniques and equipment are carefully selected to ensure a strong and durable bond, meeting the requirements of structural applications.

- Q: How is steel used in the construction of high-rise buildings?

- Steel is commonly used in the construction of high-rise buildings due to its strength, durability, and flexibility. It is used as the primary structural material, providing a sturdy framework that can withstand the weight and forces exerted on tall buildings. Steel beams and columns are used to support the floors, walls, and roof, allowing for open and spacious interior designs. Additionally, steel is utilized in the construction of elevator shafts, stairwells, and other critical components of high-rise buildings, ensuring their stability and safety.

- Q: What are the applications of steel forgings in the oil and gas industry?

- Steel forgings have numerous applications in the oil and gas industry. They are commonly used in critical components such as valves, flanges, wellheads, and drilling equipment. The high strength and durability of steel forgings make them ideal for withstanding extreme operating conditions, including high pressure and temperature environments. Additionally, steel forgings offer excellent resistance to corrosion, erosion, and fatigue, ensuring the long-term reliability and safety of oil and gas facilities.

Send your message to us

Electronical Hot Rolled Galvanized Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords