Electrolytic Tinplate of Prime Quality for Chemical Industrial Use 0.34mm Thickness

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Electrolytic Tinplate of Prime Quality for Chemical Industrial Use 0.34mm Thickness Description

Electrolytic Tinplate is a thin steel sheet coated by tin. It has an extremely beautiful metallic luster as well as excellent properties in corrosion resistance, solder ability, and weld ability.

2.Main Features of the Electrolytic Tinplate of Prime Quality for Chemical Industrial Use 0.34mm Thickness

Appearance – Tinplate is characterized by its beautiful metallic luster. Products with various kinds of surface roughness are produced by selecting the surface finish of the substrate steel sheet.

Paintability and printability – Tinplates have excellent paintability and printability. Printing is beautifully finished using various lacquers and inks.

Formability and strength – Tinplates have got very good formability and strength. By selecting a proper temper grade, appropriate formability is obtained for different applications as well as the required strength after forming.

Corrosion resistance – Tinplate has got good corrosion resistance. By selecting a proper coating weight, appropriate corrosion resistance is obtained against container contents. Coated items should meet 24 hour 5 % salt spray requirement.

Solderability and weldability – Tinplates can be joined both by soldering or welding. These properties of tinplate are used for making various types of cans.

Hygienic – Tin coating provides good and non toxic barrier properties to protect food products from impurities, bacteria, moisture, light and odours.

Safe – Tinplate being low weight and high strength makes food cans easy to ship and transport.

Eco friendly – Tinplate offers 100 % recyclability.

Tin is not good for low temperature applications since it changes structure and loses adhesion when exposed to temperatures below – 40 deg C.

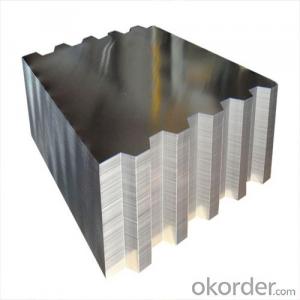

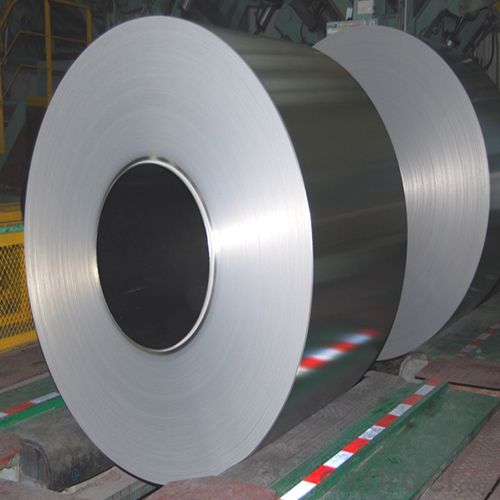

3. Electrolytic Tinplate of Prime Quality for Chemical Industrial Use 0.34mm Thickness Images

4.Electrolytic Tinplate of Prime Quality for Chemical Industrial Use 0.34mm Thickness Specification

Standard: ISO 11949 -1995

Material: MR

Thickness:0.34mm

Width: 600mm

Temper: T3

Annealing: BA

Coil Inner Diameter: 508mm

Weight: 6-10 tons/coil 1~1.7 tons/sheets bundle

Passivation:311

Oil: DOS

Surface: Finish

5.FAQ of Electrolytic Tinplate of Prime Quality for Chemical Industrial Use 0.34mm Thickness

- How are the tinplates specified?

The tinplates are specified as per the steel base, extent of tempering, the coating weight, annealing method and the surface finish.

- How many types there are for base steels?

The base steels are of three types: Type MR, L, D

- Q: How does tinplate perform in terms of lightness and portability?

- Tinplate performs exceptionally well in terms of lightness and portability. It is a lightweight material that allows for easy handling and transportation, making it highly suitable for various applications requiring mobility.

- Q: Is tinplate safe for food contact?

- Yes, tinplate is safe for food contact. It is commonly used for food packaging as it is non-toxic, resistant to corrosion, and provides an effective barrier against moisture, oxygen, and light.

- Q: What are the advantages of using tinplate for paint cans?

- There are several advantages of using tinplate for paint cans. Firstly, tinplate is highly resistant to corrosion, ensuring that the paint cans remain durable and do not rust over time. Secondly, tinplate has excellent sealing properties, preventing any leakage or evaporation of the paint. Additionally, tinplate is lightweight and easy to handle, making it convenient for transportation and storage. Lastly, tinplate is a sustainable choice as it is recyclable, contributing to environmental conservation efforts.

- Q: What are the main applications of tinplate in the photography industry?

- Tinplate is commonly used in the photography industry for the production of film canisters and film backing, which are essential components for storing and protecting photographic film. Tinplate's durability, lightness, and ability to provide airtight protection make it an ideal material for these applications. Additionally, tinplate can also be used for the production of photographic chemicals and toners, ensuring their safe and efficient storage.

- Q: How is tinplate protected during transportation and storage?

- Tinplate is protected during transportation and storage through various measures such as applying protective coatings, using packaging materials like wooden crates or pallets, and ensuring proper handling and storage conditions to prevent damage from moisture, corrosion, and physical impact.

- Q: What are the properties of tinplate?

- Tinplate is a type of steel coated with a thin layer of tin, which gives it several advantageous properties. It is highly corrosion resistant, making it ideal for packaging food and beverages. Tinplate is also malleable, allowing it to be easily formed into various shapes and sizes. It has excellent solderability, enabling tight and secure seals. Additionally, tinplate offers good heat resistance, electrical conductivity, and is lightweight.

- Q: How does tinplate perform in extreme temperatures?

- Tinplate performs well in extreme temperatures due to its high melting point and excellent heat resistance properties. It remains stable and maintains its mechanical strength even under extreme heat or cold conditions, making it a reliable material for various applications in extreme temperature environments.

- Q: What are the different ways to stack tinplate cans?

- There are several different ways to stack tinplate cans, including the straight stack, pyramid stack, interlocking stack, and the crisscross stack. Each method offers its own advantages and considerations in terms of stability, space efficiency, and ease of access.

- Q: Can tinplate be used for shipping containers?

- Yes, tinplate can be used for shipping containers. Tinplate is a type of steel coated with a thin layer of tin, which provides corrosion resistance and durability. This makes it suitable for shipping containers as it helps protect the container from rust and external damage during transportation and storage.

- Q: How does tinplate packaging contribute to product protection against oxidation?

- Tinplate packaging provides a protective barrier against oxidation due to its inherent properties. The tin coating on the steel surface acts as a barrier, preventing oxygen from coming into direct contact with the product inside the packaging. This barrier effectively slows down or prevents the oxidation process, preserving the quality and shelf-life of the product. Additionally, tinplate packaging is resistant to corrosion, ensuring the integrity of the package and further safeguarding against oxidation.

Send your message to us

Electrolytic Tinplate of Prime Quality for Chemical Industrial Use 0.34mm Thickness

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords