Electrolytic Tinplate of Prime Quality for Chemical Use 0.32mm Thickness

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Electrolytic Tinplate of Prime Quality for Chemical Use 0.32mm Thickness Description

Electrolytic Tinplate, is one thin steel sheet with a coating of tin applied by electrolytic deposition. Tinplate made by this process is essentially a sandwich in which the central core is strip steel. This core is cleaned in a pickling solution and then fed through tanks containing electrolyte, where tin is deposited on both sides. As the strip passes between high-frequency electric induction coils, it is heated so that the tin coating melts and flows to form a lustrous coat.

2.Main Features of the Electrolytic Tinplate of Prime Quality for Chemical Use 0.32mm Thickness

The salient feature of DR Tinplate is the combination of higher strength and sufficient ductility, which enables much thinner Tinplate to be used, compared to Single Reduced Tinplate resulting in Substantial economic savings.

According to the steel chemistry and annealing process, the second reduction (DR08) can be between 27% to 40%, thereby producing strengths upto 550 +/-50 N/mm2, whereas single reduced material has strength less than 450 N/mm2 &DR 09 (Hard DR) is produced at temper mill with reduction % in range of 27-35 % & will strength upto 690 N/mm2 to the produced material.

Tinning is the process of thinly coating sheets of wrought iron or steel with tin, and the resulting product is known as tinplate. It is most often used to prevent rust.

While once more widely used, the primary use of tinplate now is the manufacture of tin cans. Formerly, tinplate was used for cheap pots, pans and other holloware.

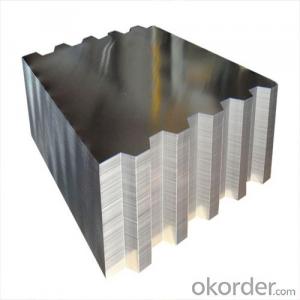

3.Electrolytic Tinplate of Prime Quality for Chemical Use 0.32mm Thickness Images

4.Electrolytic Tinplate of Prime Quality for Chemical Use 0.32mm Thickness Specification

Standard: ISO 11949 -1995, GB/T2520-2000,JIS G3303,ASTM A623, BS EN 10202

Material: MR

Thickness:0.32mm

Width: 600mm -1150mm

Temper: T1-T5

Annealing: BA & CA

Coil Inner Diameter: 508mm

Weight: 6-10 tons/coil 1~1.7 tons/sheets bundle

Passivation:311

Oil: DOS

Surface: Finish,bright,stone,matte,silver

5.FAQ of Electrolytic Tinplate of Prime Quality for Chemical Use 0.32mm Thickness

- How are the tinplates specified?

The tinplates are specified as per the steel base, extent of tempering, the coating weight, annealing method and the surface finish.

- How many types there are for base steels?

The base steels are of three types: Type MR, L, D

- Q: How is tinplate coated for paint cans?

- Tinplate is typically coated for paint cans by applying a thin layer of protective material, such as lacquer or polymer, onto the surface of the tinplate. This coating acts as a barrier to prevent the metal from coming into direct contact with the paint, ensuring the can remains corrosion-resistant and the paint remains uncontaminated.

- Q: Can tinplate be used for automotive components?

- Yes, tinplate can be used for automotive components. Tinplate is a type of steel coated with a thin layer of tin, which provides corrosion resistance and aesthetic appeal. It is commonly used in the automotive industry for various components such as fuel tanks, oil pans, and engine covers.

- Q: Can tinplate be used for kitchenware?

- Yes, tinplate can be used for kitchenware. Tinplate is a type of steel coated with a thin layer of tin, which provides corrosion resistance and makes it suitable for food contact applications. It is commonly used for making cans, containers, and other kitchen utensils due to its durability, easy cleaning, and ability to keep food fresh.

- Q: How does tinplate packaging contribute to product protection against pests?

- Tinplate packaging provides a strong barrier against pests due to its durability and resistance to punctures or tears. It effectively prevents insects, rodents, and other pests from accessing the products inside, safeguarding them against potential contamination or damage.

- Q: How does tinplate compare to glass in terms of packaging applications?

- Tinplate has several advantages over glass in terms of packaging applications. Firstly, tinplate is much lighter than glass, making it easier and cheaper to transport. Additionally, tinplate is more durable and less prone to breakage than glass, reducing the risk of product damage during handling and shipping. Moreover, tinplate provides a better barrier against air, moisture, and light, ensuring the preservation and quality of the packaged goods. Lastly, tinplate is more cost-effective than glass, making it a preferred choice for many packaging applications.

- Q: How does tinplate perform in terms of moisture resistance?

- Tinplate performs exceptionally well in terms of moisture resistance. The tin coating on the steel substrate acts as a barrier, preventing moisture from coming into contact with the metal and causing corrosion. This makes tinplate highly suitable for packaging applications where moisture protection is crucial, ensuring the preservation and integrity of the contents.

- Q: What are the different testing methods for tinplate packaging?

- Some of the different testing methods for tinplate packaging include visual inspection for defects or damage, measuring the thickness of the tinplate using a micrometer, performing drop tests to assess the durability and impact resistance of the packaging, conducting leakage tests to ensure the integrity of the seals, conducting corrosion resistance tests to evaluate the tinplate's resistance to rust or corrosion, and conducting performance tests to assess the packaging's ability to withstand various environmental conditions and mechanical stresses.

- Q: How does tinplate perform in terms of fire resistance?

- Tinplate has poor fire resistance as it is made of thin steel coated with a layer of tin, which can easily melt or deform under high temperatures, making it susceptible to fire.

- Q: What are the main applications of tinplate in the sports equipment industry?

- Tinplate is commonly used in the sports equipment industry for various applications such as packaging and protection for items like tennis balls, golf balls, and other small accessories. It provides durability, corrosion resistance, and a visually appealing finish, making it ideal for packaging and keeping these items in optimal condition.

- Q: Can tinplate be used for energy storage applications?

- No, tinplate is not typically used for energy storage applications. It is more commonly used for packaging purposes due to its ability to protect contents from external elements.

Send your message to us

Electrolytic Tinplate of Prime Quality for Chemical Use 0.32mm Thickness

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords