Electrolytic Tinplate Coils of Prime Quality for Chemical Industrial Use 0.34mm Thickness

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Electrolytic Tinplate Coils of Prime Quality for Chemical Industrial Use 0.34mm Thickness Description

Electrolytic Tinplate, is one thin steel sheet with a coating of tin applied by electrolytic deposition. Tinplate made by this process is essentially a sandwich in which the central core is strip steel. This core is cleaned in a pickling solution and then fed through tanks containing electrolyte, where tin is deposited on both sides. As the strip passes between high-frequency electric induction coils, it is heated so that the tin coating melts and flows to form a lustrous coat.

2.Main Features of the Electrolytic Tinplate Coils of Prime Quality for Chemical Industrial Use 0.34mm Thickness

The origin of tinplate is from Bohemian, from 14th century, the people there began to produce tinplate. Also known as electrolytic tinplate, which stand for tin coating on the surface of cold rolled coil for preventing rust. The unique characteristics of tinplate steel decides its comprehensive range of application in international tinplate packaging industry. With the abundance extend of CC and DR steel material, and tin free steel, which enhance the development of technology of packaging industrialization, the innovation is ubiquitous in tinplate steel.

The feature of anti-oxidation, various kinds and beauty in printing enable tinplate enjoys widely usage in food can package, pharmaceutical package, daily application packing, apparatus package and industrial pack.

From the first food can to be produced in the year of 1810 in British, the development trend of tinplate has become thinner thickness and less tin coating to adjust the change of can industry and save cost.

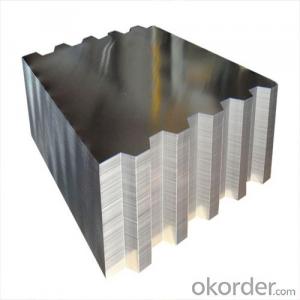

3. Electrolytic Tinplate Coils of Prime Quality for Chemical Industrial Use 0.34mm Thickness Images

4.Electrolytic Tinplate Coils of Prime Quality for Chemical Industrial Use 0.34mm Thickness Specification

Standard: ISO 11949 -1995

Material: MR

Thickness:0.34mm

Width: 600mm

Temper: T3

Annealing: BA

Coil Inner Diameter: 508mm

Weight: 6-10 tons/coil 1~1.7 tons/sheets bundle

Passivation:311

Oil: DOS

Surface: Finish

5.FAQ of Electrolytic Tinplate Coils of Prime Quality for Chemical Industrial Use 0.34mm Thickness

- How are the tinplates specified?

The tinplates are specified as per the steel base, extent of tempering, the coating weight, annealing method and the surface finish.

- How many types there are for base steels?

The base steels are of three types: Type MR, L, D

- Q: What are the main applications of tinplate in the furniture industry?

- Tinplate is widely used in the furniture industry for various applications such as decorative elements, hardware components, and protective coatings. It provides a durable and corrosion-resistant surface finish, making it ideal for metal furniture pieces. Tinplate is also commonly used in the production of metal furniture frames, as it offers excellent strength and stability. Additionally, tinplate can be utilized for intricate designs and embossing, enhancing the aesthetic appeal of furniture items.

- Q: How does tinplate compare to tin-free steel in terms of properties and applications?

- Tinplate and tin-free steel have distinct properties and applications. Tinplate, which is steel coated with a thin layer of tin, offers excellent corrosion resistance, formability, and solderability. It is commonly used in the food and beverage industry for making cans, containers, and closures due to its ability to preserve the product's quality and prevent contamination. On the other hand, tin-free steel, also known as electrolytic chromium-coated steel, provides superior paint adhesion, scratch resistance, and weldability. It finds applications in manufacturing various products like aerosol cans, automotive parts, and appliances that require durability and aesthetic appeal. Ultimately, the choice between tinplate and tin-free steel depends on the specific requirements of the application at hand.

- Q: Can tinplate be used for packaging medical devices?

- Yes, tinplate can be used for packaging medical devices. Tinplate is a strong and durable material that provides excellent protection and barrier properties to ensure the safety and integrity of medical devices. It is also resistant to corrosion and can be easily sterilized, making it suitable for packaging in the medical industry.

- Q: Can tinplate be recycled?

- Yes, tinplate can be recycled. It is made of steel coated with a thin layer of tin, and both steel and tin can be recycled indefinitely without losing their properties. Recycling tinplate helps conserve resources and reduce waste.

- Q: What are the benefits of using tinplate for electrical components?

- Using tinplate for electrical components offers several benefits. Firstly, tinplate is highly corrosion-resistant, which helps protect the components from moisture and other environmental factors that can cause damage. Additionally, tinplate has excellent electrical conductivity, ensuring efficient and reliable performance of the electrical components. Moreover, tinplate is lightweight and durable, making it suitable for various applications. Lastly, tinplate is cost-effective, as it is readily available and its production process is relatively inexpensive. Overall, these advantages make tinplate a preferred choice for electrical components.

- Q: What are the different types of tinplate printing techniques?

- The different types of tinplate printing techniques include offset lithography, screen printing, and digital printing.

- Q: What are the main factors influencing the supply of tinplate?

- The main factors influencing the supply of tinplate are the availability and cost of raw materials such as tin, steel, and other alloys, the production capacity and efficiency of tinplate manufacturers, government regulations and policies, fluctuations in demand from industries such as packaging, automotive, and electronics, and global economic conditions and trade dynamics.

- Q: Why tin tin plating?

- In nature, tin is seldom free, so there are few pure metallic tin. The most important tin ore is cassiterite, chemical composition of two tin oxide. This copper smelting tin, iron, aluminum is easy, as long as the cassiterite together with burning charcoal, charcoal will be put out in cassiterite tin reduction. Obviously, the ancient people tin place if there is fire burning when grilled wild animals, the earth would be charcoal reduction of cassiterite, tin silver and melted will flow out. Because of this, tin was discovered long ago.

- Q: How does tinplate packaging contribute to product protection against oxidation?

- Tinplate packaging provides a protective barrier against oxidation due to its inherent properties. The tin coating on the steel surface acts as a barrier, preventing oxygen from coming into direct contact with the product inside the packaging. This barrier effectively slows down or prevents the oxidation process, preserving the quality and shelf-life of the product. Additionally, tinplate packaging is resistant to corrosion, ensuring the integrity of the package and further safeguarding against oxidation.

- Q: Tinplate why have white and yellow, tin plating should be white ah, yellow is how to return a responsibility?

- Usually on the surface of a layer of oil, light oil, or iron; gold oil is golden; white is white, yellow magnetic, if printing, of course is yellow; usually tinplate can print color (color or 4C file).

Send your message to us

Electrolytic Tinplate Coils of Prime Quality for Chemical Industrial Use 0.34mm Thickness

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords