TIN FREE STEEL SHEET

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

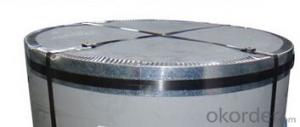

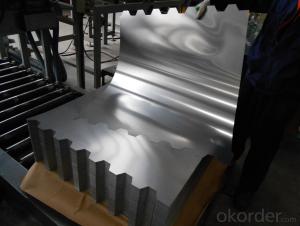

TIN FREE STEEL SHEET

1.Standard:JIS G3315-2008;GB/T24180-2009

2.Thickness:0.15-0.36mm

3.Tin Coating:2.8/2.8,5.6/5.6g/㎡

4.Width:600-1050mm

5.Temper:T2,T3,T4,T5,DR8

7.Annealing:CA,BA

8.Packing:Exported Package

9.End Use:used for tea cans,paint cans,easy-open ends,food cans,stationary and office supply,electrolytic cables

- Q: How thick is tinplate?

- Tinplate typically has a thickness ranging from 0.13mm to 0.49mm.

- Q: What are the common defects found in tinplate packaging?

- Common defects found in tinplate packaging include: 1. Corrosion: Tinplate can be prone to corrosion, resulting in rust spots or holes in the packaging. This can compromise the integrity of the packaging and affect the quality and safety of the product inside. 2. Dents and scratches: During handling or transportation, tinplate packaging can get dented or scratched. These defects can be purely cosmetic, but in some cases, they may lead to leaks or damage to the product. 3. Poor sealing: Improper sealing of tinplate packaging can lead to leaks or contamination of the product. This can occur due to faulty machinery or inadequate quality control during the packaging process. 4. Print defects: Tinplate packaging often includes printed information or branding. Common defects in this area include misalignment, smudging, fading, or incomplete printing. These defects can affect the visual appeal of the packaging and the overall product presentation. 5. Manufacturing defects: Tinplate packaging can sometimes have manufacturing defects such as uneven edges, poor welds, or misaligned seams. These defects may weaken the packaging structure or cause sharp edges that could potentially harm consumers. It is important for manufacturers to have strict quality control measures in place to identify and rectify these defects, ensuring the safety, functionality, and aesthetics of tinplate packaging.

- Q: What are the key properties of tinplate?

- The key properties of tinplate include excellent corrosion resistance, high strength, good formability, and the ability to be easily soldered and welded.

- Q: What are the welding methods used for tinplate?

- The welding methods commonly used for tinplate are spot welding, seam welding, and resistance welding. These methods ensure a strong and durable bond between tinplate sheets, making them suitable for various applications such as food cans and packaging materials.

- Q: Can tinplate be shielded?

- With the production of mobile phone shielding materials I know the ocean (Cupronickel), copper, tin phosphor bronze (TIN), these three kinds of material weldability are very good, because the surface of tin!

- Q: Can tinplate be embossed?

- Yes, tinplate can be embossed.

- Q: What are the advantages of using tinplate for shipping containers?

- There are several advantages of using tinplate for shipping containers. Firstly, tinplate is highly durable and provides excellent protection against corrosion, ensuring the safety and integrity of the goods being transported. Secondly, tinplate is lightweight yet strong, making it easier to handle and transport containers efficiently. Additionally, tinplate is easily recyclable, making it an environmentally friendly choice. Lastly, tinplate has a smooth surface which can be easily cleaned and sanitized, reducing the risk of contamination during shipping.

- Q: Can tinplate packaging be used for frozen or refrigerated goods?

- Yes, tinplate packaging can be used for frozen or refrigerated goods. Tinplate is a durable material that provides excellent protection against moisture and temperature changes, making it suitable for storing and transporting perishable items. It helps to maintain the freshness and quality of frozen or refrigerated goods, making it a popular choice in the food industry.

- Q: Can tinplate be used for automotive applications?

- Yes, tinplate can be used for automotive applications. Tinplate is a type of steel coated with a thin layer of tin, which provides corrosion resistance and enhances the appearance of the material. Its properties, such as strength, formability, and weldability, make it suitable for various automotive components like body panels, fuel tanks, and battery enclosures. Additionally, tinplate is lightweight, which helps improve fuel efficiency in vehicles.

- Q: Can tinplate be used for petrochemical packaging?

- Yes, tinplate can be used for petrochemical packaging. Tinplate is a commonly used material in the packaging industry due to its excellent properties such as corrosion resistance, durability, and ability to preserve the quality of the contents. It is suitable for packaging various products, including petrochemicals, as it provides a protective barrier against moisture, oxygen, and other contaminants. Additionally, tinplate can be easily shaped into different forms, making it versatile for packaging different shapes and sizes of petrochemical products.

Send your message to us

TIN FREE STEEL SHEET

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords