Tin Free Steel MR Grade for Oil Can Packaging

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 30000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Products: Tin Free Steel

Tinplate and TFS are widely used for making all types of containers such as artistic cans, tea cans, painting cans, chemical package cans and metal printing etc. Its applications are not limited to containers; recently, they have also been used for making electrical machinery parts and many other products.

2. Specification:

Our goods enjoyed high quality both at home and abroad. We can supply tin free steel as follows:

Technical standard | JISG3315 and GB/T24180 - 2009 (BS EN 10202:1990) |

Steel Type | MR / SPCC |

Thickness | From 0.15mm to 0.50mm (Tolerance +/- 0.01mm) |

Width | Normally 600-1050mm (Tolerance +3/-0 mm) |

Coating | Total chromium min 30mg/m2 max 140mg/m2 |

Temper & Annealing | T1-T5, DR7-8, TS230-TH435, T49-T65(+/- 4) |

Surface Treatment | Bright & Fine Stone & Stone & Silver & Matt |

Payment terms | Letter of Credit (L/C), Telegraphic transfer (T/T) |

Price terms | CFR & CIF price term |

Delivery time | Within 60 days after received L/C or T/T down payment |

Packing | High quality shipping packing which contains thin plastic film, rust-proof paper, metal cover, metal angles and strap sand pallet. |

Minimum order Quantity(MOQ) | 25 metric tons (1X 20'' container) |

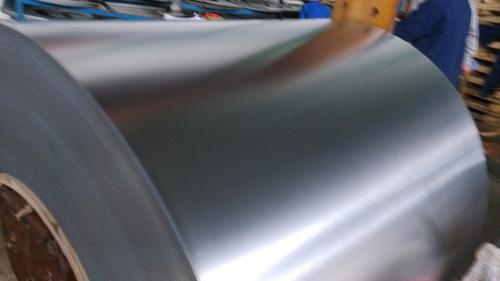

3. Pictures:

4. Features of the factory price/ tin free steel/tinplate/tfs/tmbp/etp/spte:

Beautiful Appearance

Excellent Paintability & Printability

Excellent Formability & Strength

Excellent Corrosion Resistance

Excellent Solderability & Weldability

5. FAQ:

We are one of the main producers in China for tinplate, tin free steel and also TMBP. At present, our productivity is more than 450000 MT/year.

For more information about our products or company, pls contact us freely.

- Q: How does tinplate perform in terms of resistance to humidity?

- Tinplate performs exceptionally well in terms of resistance to humidity. The tin coating on the steel substrate provides a protective barrier that prevents moisture from reaching the metal, thus minimizing the risk of rust and corrosion. This makes tinplate an ideal packaging material for products that are sensitive to moisture, ensuring their integrity and longevity.

- Q: What are the advantages of using tinplate?

- There are several advantages of using tinplate. Firstly, tinplate is highly durable and resistant to corrosion, making it ideal for packaging and storage purposes. Additionally, tinplate is lightweight and easily formable, allowing for versatility in design and easy transportation. It also provides a high level of protection to the contents, preventing spoilage or contamination. Moreover, tinplate is recyclable and environmentally friendly, contributing to sustainability efforts. Lastly, tinplate has excellent printability, allowing for attractive and eye-catching designs, enhancing product visibility and branding.

- Q: Is tinplate safe for food contact?

- Yes, tinplate is safe for food contact. It is commonly used for food packaging as it is non-toxic, resistant to corrosion, and provides an effective barrier against moisture, oxygen, and light.

- Q: Can tinplate be used for promotional and gift items?

- Yes, tinplate can be used for promotional and gift items. Tinplate is a versatile material that can be easily molded into various shapes and sizes, making it suitable for creating unique and customized promotional and gift items. Additionally, tinplate offers excellent printing capabilities, allowing for vibrant and eye-catching designs, making it an ideal choice for branding purposes.

- Q: How does tinplate packaging contribute to product portion control?

- Tinplate packaging contributes to product portion control by providing a sturdy and reliable container that can be designed and manufactured in specific sizes. This allows manufacturers to package their products in predetermined portions, making it easier for consumers to control their intake and avoid overconsumption. Additionally, the durability of tinplate packaging ensures that the portioned products remain intact and fresh until they are consumed, further promoting portion control.

- Q: How is tinplate stored and transported?

- Tinplate is typically stored and transported in rolls or sheets. It is commonly packaged in coils and secured with strapping or wrapping to prevent damage during transportation. These coils or sheets are then loaded onto trucks, ships, or trains for distribution to manufacturers and consumers. Additionally, proper handling and storage conditions are crucial to maintain the quality of tinplate, such as protecting it from moisture, extreme temperatures, and physical impact.

- Q: How to open cans

- Swiss Army knife, it has opened the canned fruits with tools under the hook can cover the exterior edge of front edge force canned fruit like a ring, groove cover on the edge of... The pressure inside a circle, do not pay attention to the head word screwdriver pressed in, or it may have wear. Under the hook can cover the exterior edge of front edge force under pressure can, like a ring groove on the side of the roof... Pressed in a circle, do not pay attention to the head word screwdriver pressed in, or you may wear. This tool is also very easy to use.

- Q: What are the advantages of using tinplate for household appliances?

- There are several advantages of using tinplate for household appliances. Firstly, tinplate is highly resistant to corrosion, making it ideal for appliances that come in contact with water or other liquids. This corrosion resistance ensures the longevity of the appliance, reducing the need for frequent replacements. Secondly, tinplate has excellent heat resistance properties, making it suitable for appliances that generate high temperatures. This heat resistance allows for efficient heat transfer and prevents warping or damage to the appliance. Additionally, tinplate is lightweight yet sturdy, making it easy to handle and transport while maintaining durability. Lastly, tinplate is a sustainable material as it is 100% recyclable, reducing environmental impact and promoting a circular economy.

- Q: How is tinplate tested for quality control?

- Tinplate is tested for quality control through various methods such as visual inspection, chemical analysis, and mechanical testing. Visual inspection involves checking for any defects or imperfections on the surface of the tinplate, ensuring it meets the required standards. Chemical analysis is performed to determine the composition of the tinplate, ensuring it contains the appropriate levels of tin and other alloying elements. Mechanical testing involves subjecting the tinplate to various stress tests to assess its strength, ductility, and resistance to corrosion. These quality control measures help ensure that tinplate meets the necessary standards for its intended use.

- Q: What are the common printing and decoration techniques for tinplate?

- Some common printing and decoration techniques for tinplate include lithography, offset printing, embossing, and metalizing. Lithography involves transferring an image onto the tinplate using a printing plate. Offset printing is a similar technique that uses a rubber blanket to transfer the image. Embossing creates raised or recessed patterns on the tinplate, adding texture and depth. Metalizing involves coating the tinplate with a thin layer of metal, such as aluminum or gold, to create a reflective surface. These techniques are commonly used to enhance the visual appeal and branding of tinplate products.

Send your message to us

Tin Free Steel MR Grade for Oil Can Packaging

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 30000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords