Electric Aluminium Work Platform(six masts)-JAMWP6000

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

| Model | JAMWP18-6000 | JAMWP20-6000 | ||

| Safe working load | kg | 160 | ||

| Extending platform safe working load | kg | 120 | ||

| (forbidden when lifting) | ||||

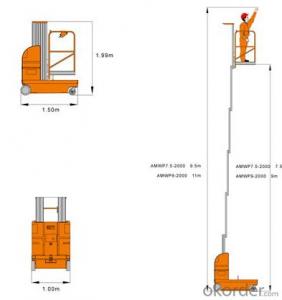

| Maximum working height | mm | 18000 | 20000 | |

| Max platform height | mm | 16000 | 18000 | |

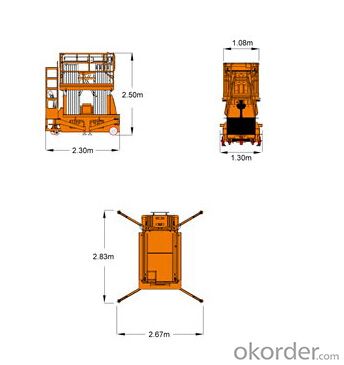

| Overall length | mm | 2300 | ||

| Overall width | mm | 1300 | ||

| Overall height | mm | 2500 | ||

| Working platform size | mm | 1600×1080 | ||

| Platform extending Length | mm | 750×1080 | ||

| Minimum ground clearance | mm | 100 | ||

| Wheelbase | mm | 1790 | ||

| Min turning radius inner/outer wheel | mm | 2.5/4.6 | ||

| Driving motor | 24VDC/1.5KW | |||

| Lifting motor | four masts | 24VDC/3KW | ||

| dual masts | 24VDC/1.5KW | |||

| Travel Speed | km/h | 4 | ||

| Lifting/ descending speed | sec | 110/80 | 120/90 | |

| Accumulator | 4×6V/250Ah | |||

| Lifting | four masts | 4×6V/250Ah | ||

| dual masts | 2×12V/120Ah | |||

| Charger | 24V/15-30A | |||

| Gradeability | % | 15 | ||

| Driving wheel | mm | Ф254×80 | ||

| Front wheel | in | 10 | ||

| Rear wheel | in | 6 | ||

| Overall weight | kg | 2310 | 2380 | |

Standard Configuration

-Emergency stop button

-Charge indicator

-Double brakers

-Voltage display

-Strut bar for safe overhaul

-Emergency descending button

-Driving motor overtemperature protection

-Overload limit

-High capacity traction battery

- Q: How much is the 8 square meter tatami mat

- Wants to see you with what kind of wood, to make what kind of structure, whether or not to do lifting platform, finally, custom matching straw mat, ranging from several thousand to tens of thousands of, I will ask carpenter in my attic made a simple platform of more than 20 cm from the ground to add a row of little cupboard (pictured)

- Q: What about the platform of southworth?

- With more than 120 years of experience in equipment design and manufacturing, sotheby's has become a leader in the global elevator industry. Shanghai sotheby voss now completely using the quality control and technical standards in the United States, hydraulic parts, valve block key accessories all imports from the United States, such as steel structure USES the best of the domestic steel production, the greatest degree of guarantee the product quality and stability.

- Q: There are several reasons for the hydraulic cylinder oil leak on the elevator

- The sealing part of the seal is worn out to buy two oil seals according to oil cylinder model to change to be good also a few dollars

- Q: Hydraulic platform repair work instruction book, trouble which big man helps to provide

- The maintenance system of elevators is maintained every month. Roller, intermediate shaft and bearing, oil cylinder pin shaft and bearing, arm hinge shaft and bearing, etc. All parts are filled with lubricating oil to extend the life of the bearing.

- Q: How to use the ball screw platform?

- Second, heyman screw can see lu, platform settled on first use, carefully to see if there are any more abnormal hydraulic parts, electrical appliances, layout, to ensure that no more than about geomagnetic held before commissioning, no-load again after 3 ~ 5 times a load test.

- Q: Can the stepping motor drive the hydraulic platform?

- The hydraulic platform is driven by an oil cylinder, and the motor drive is a completely different way through mechanical means (screw, chain, gear, rack, etc.). In addition to mechanical means, depending on the power size, the step motor usually means that the equivalent power is not much, the maximum is a few hundred watts. The hydraulic platform is generally heavy, so it's unlikely. Or do you use a step motor to drive the hydraulic pump? It can, but also to consider the power problem, said earlier, smaller power stepping motor, if the original motor is a few kilowatts, certainly not.

- Q: The advantages and disadvantages of using diesel engine as an engine

- The fuel consumption is significantly lower than the steam engine power plant. Economical and practical, diesel fuel is low in the same kind of fuel, so it is easy to accept.

- Q: What happens when the platform comes up and the power goes out.

- In pump station oil outlet on the right side with a nut, the nut off, is within the six-party of the screw, counterclockwise, the platform can fall, fall after what must tighten screw clockwise, the back nut, so that next time can normal use

- Q: How to maintain the platform?

- My company has, our brand: niu power Throughout guangdong, there are 57 dealers across the country. Check it online, it's ok to buy it, but at least it will give you advice and contrast!

- Q: The hydraulic cylinder with hydraulic platform is changed to whether the cylinder is feasible

- As long as your cylinder size is large enough, theoretically! But in practice, it's not feasible to think about space and so forth.

Send your message to us

Electric Aluminium Work Platform(six masts)-JAMWP6000

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches