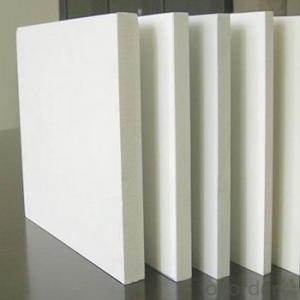

Plastic Sheets - Economic PVC Sheet, PVC Foam Board & WPC Board

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

We are specialized in manufacturing PVC foam board.

Standard Size We Provide as below:

-1220*2440mm,Thickness:1mm-25mm

-1560*3050mm,Thickness:1mm-20mm

-2050*3050mm,Thickness:1mm-18mm

Applications :

-Advertising Signs

-Displays

-Exhibition Stands

-Point of Sale

-Interior Designs

-Bathroom Fittings

-Models & Prototypes

-Panels & Cabins

-Embossing & Engraving

-Thermoforming

-Lumber

-Trimboard

Features:

1. Waterproofing of pvc foam board .

2. Fire retardant and self-extinguishing of pvc foam board .

3. Heat preservation of pvc foam board .

4. Sound-insulated.

5. Insulation of pvc foam board .

6. Non-corrosion.

7. Non-toxic.

8. Tough, rigid with the high impact strength.

9. Stable color retention.

10. Dampproof.

11. Anti - deformed pvc foam board .

PVC Foam Board Feature:

1. waterproof, fire retardant, acid and alkali, moth, light, heat, noise, vibration characteristics;

2. equal and wood processing, and processing performance is far superior to wood;

3. wood, aluminum, composite board ideal alternative;

4. crust plate surface is very smooth, high hardness, not easy scratches, commonly used in the production of cabinets, furniture;

Picture

- Q: I have an idea for something I would like to make and sell. I would like to be able to stamp or cut a fairly simple shape out of flexible plastic sheets, a bit like margarine tub plastic. What machine/device/tool would I need to be able to cut or stamp this shape (and yes, I know scissors would work, but I would like to be able to make quite a few)

- A die cutter is one method. You can see simple versions at craft stores, it is like a cookie cutter with a sharpened edge. However, these cost a bit to have custom made, and they get dull. A CNC milling machine or Laser cutter could cut these out. A computer controlled engraving machine with the right bit could do this, too. The drawback is that it isn't incredibly fast, but you can change the shape at any time. CNC stands for Computer Numerical Control, what that means is that, like a Laser cutter you draw it on the computer. Then it uses a small spinning bit to cut out the plastic. Engraving machines are purpose-built CNC milling machines.

- Q: filled bubbles. the lenses in these sheets are advertised to focus heat from the sun into the water and raise its temperature. do you think the lenses of such sheets do in fact direct more solar energy into the water?

- No those can no longer via fact the whole component of the lenses isn't grater then the pool the whole image voltaic that falls on the pool maintains to be comparable, or perhaps much less via fact some gentle is absorbed in sheet. yet sheet can help in heating the water via fact it do no longer enable water to unfastened warmth via evaporation It acts as like a greenhouse shelter

- Q: What are the bending capabilities of plastic sheets?

- The bending capabilities of plastic sheets depend on various factors such as the type of plastic, thickness, and temperature. Generally, plastic sheets can be easily bent or formed into various shapes when heated to their specific temperature range. This process is known as thermoforming. However, some plastics have higher rigidity and may require more heat or additional techniques like scoring or using a bending machine to achieve the desired bend.

- Q: as thick as ,5mm to 1.2mmdon't say try google or something stupid like that(a webstore please)

- Find a hospital supply store also there are drugs to take to stop bed wetting. See your doctor for more info.

- Q: What are the different types of plastic used in plastic sheets?

- There are various types of plastic used in plastic sheets, including acrylic, polycarbonate, polyethylene, polypropylene, and PVC (polyvinyl chloride). Each type of plastic has its own unique properties and characteristics, making them suitable for different applications such as signage, packaging, construction, and more.

- Q: Can plastic sheets be used for noise reduction barriers?

- Yes, plastic sheets can be used for noise reduction barriers. They are often used in construction projects or industrial settings to minimize noise transmission and provide a relatively cost-effective solution for noise control.

- Q: Are plastic sheets resistant to staining?

- Yes, plastic sheets are generally resistant to staining due to their non-porous nature, which prevents liquids or substances from penetrating the surface and causing permanent discoloration.

- Q: Port Richey, FL area dealer for Lexan plastic sheets, 4'x8'.?

- Too expensive, buy approved metal shutters.

- Q: Can plastic sheets be used for packaging materials?

- Yes, plastic sheets can be used as packaging materials. They are commonly used in various industries for packaging products due to their durability, flexibility, and ability to protect against moisture and contamination. Plastic sheets can be molded or formed into different shapes and sizes to accommodate various packaging needs.

- Q: How do you clean plastic sheets?

- To clean plastic sheets, start by wiping off any loose dirt or debris with a soft cloth or sponge. Then, mix a mild detergent with warm water and gently scrub the sheets using a soft brush or cloth. Rinse thoroughly with clean water and allow them to air dry. Avoid using harsh chemicals or abrasive materials that can damage the plastic.

Send your message to us

Plastic Sheets - Economic PVC Sheet, PVC Foam Board & WPC Board

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords