Mosaic Fiberglass Mesh - e-glass Fiberglass Wall Mesh for Architectural Material

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 3000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Mesh for Construstion Material

Product Description

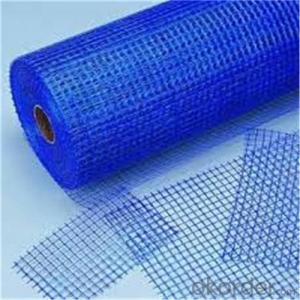

Fiberglass Mesh Made of C or E glass fiber yarn through special weaving technique,

then coated by the anti-alkali and reinforcing agent and treated by high temperature heat finishing.

It is ideal engineering material in construction and decoration industry!

fiberglass mesh High Quality

1. Coating glue: our coating glue is produced by Germany BASF which can keep more than 70% after 28 days NaoH test.

2. Our fiberglass yarn is supplied by Jushi Group which is the largest producer of fiberglass yarn in the world like Saint Gobain, it is more 20% strong strength and beauty surface than normal fiberglass yarn.

fiberglass mesh Application

1.Fiberglass mesh is Wall reinforced material (such as fiberglass wall mesh, GRC wall panels, EPS insulation with the wall board, gypsum board, bitumen)

2. Reinforced cement products.

3. Used for Granite, mosaic, marble back mesh etc.

4.Waterproof membrane fabric, asphalt roofing.

Certificates to guarantee quality.

Passed in ISO9001:2000 certificate , IQ net, China National test, ROSH,Europe ETAG certificate

Company information :

Advantage:

1.CNBM International is a subsidiary of the CNBM Group

2.The largest building materials and equipment group in China

3.Government owned compny

4.Owned our logistics parkand in Dubai

Our service :

1.Any time you can contact with us

2.Free sample

3.If you place order ,we will update the new production process to you

4.Every order,we will make professtional inspecting

5.If you have any feedback , we will first time to make it for you

6.We will all stand your side to consider everything

Fiberglass mesh Payment:

T/T 30% in advance, T/T 70% against B/L copy.

FAQ:

Q: What are we doing?

A: we offer the best fiberglass mesh with the right price, we make the best ones , and also offer sourcing service for many products

Q: What are we making in our own factory?

A: we are one of the best fiberglass mesh supplier in China. We own and co-own the best fiberglass mesh factory, and we also make many accessories in our own factory, So we have many exclusive products that is only available from us.

Q: How is our customer service?

A: All our sales representatives can speak fluent English. They will answer all of your questions within 24 hours.

Q: What others can we offer?

A: Based on the wide products range, we offer the best one-step sourcing services. We will definitely save you a lot of time and money, and based on our quantity of shipment, we can get the best shipping service from the best forwarders. This will help you to save a lot on shipment.

- Q: The difference between glass wool and mineral wool insulation

- Centrifugal glass wool is glass as the main raw material according to certain proportion and various other materials mixed into the glass melting furnace fully melted, the solution is good after melting into the bushing out of the centrifuge. In the centrifuge speed driven, centrifugal high-speed operation is thrown into the glass glass flow in high temperature and high speed flame under the effect of glass fiber tensile trickle further, and then applying the spray adhesive, in the negative wind effect of cotton belt, attached to the resin bonding agent fiber deposition in motion the mesh belt, formed a uniform cotton blanket, and then by the constant temperature oven curing, the curing process is complete, the product type, shape after cutting became a predetermined product, and then packaged.Rock wool products with exquisite is basalt as main raw materials, by high temperature melting, made of inorganic fiber by centrifugal equipment, and then adding a special binder and dust-proof oil by swinging through the special equipment and fiber felt the changes of fiber arrangement structure, the new light finally made by the setting and thermal insulation materials. According to the different uses can be processed into rock wool board rock wool, blanket, rock wool pipe shell and other products.

- Q: How to DIY the setting adhesive of glass fiber gridding cloth?

- With glass fiber woven fabric as base material, gridding cloth is dipped in and coated with highly resistant polymer emulsion, thus featured by good alkali resistance, flexibility and high tensile resistance in the bidirection of warp and weft. It is widely used for thermal insulation, water proofing and crack resistance of internal and external walls of buildings. The glass fiber gridding cloth mainly adopts alkali glass fiber yarn (with silicate, stability as main components) and made by high-temperature heat setting such as anti alkali liquid and strengthening agent of the special organization structure - lace stitch.

- Q: Dust screen can really dust-proof? Dust screen window shopping tips

- Sold on the market. The texture is polyester mesh and nuclear pore membrane, the former is a filter material production, which is a new type of microporous membrane developed abroad in 70s, so can prevent air pollution and dust screen PM2.5 to a certain extent, keep indoor air fresh.

- Q: How to choose glass fiber filter cartridge

- Then the adhesive, adhesive dust filter must choose special bonding glue quality, and glue injection amount must be sufficient, it is different from the air filter of automobile relative strength requirement is not too high, there will be dust filter pulse cleaning pressure kept throughout the cartridge 6 kg at work so, the glue is not good or too little amount of glue injection cartridge cover is easy to fall off.

- Q: Alkali resistant products of gridding cloth

- With middle-alkali or alkali-free glass fiber gridding cloth as base material, glass fiber gridding cloth is made by processing with alkali resistant coating. It is featured by high strength, good alkali resistance and crack resistance. It plays an important role in insulation system. Due to its excellent excellent resistance to corrosion of chemicals such as acid and alkali and high tensile resistance in the bidirection of warp and weft, it can evenly disperse stress of external wall insulation system and prevent the deformation of the whole insulation structure caused by shock and squeezing of external force, thus making it featured by high shock resistance and easy construction and control. Therefore, it plays a role of soft rebar in insulation system.

- Q: When the outer insulation lacquer decorative glass fiber cloth can do it

- Can not even produce tiny cracks cause surface cracking phenomenon of stress using the grid cloth to prevent precausions mortar contraction.

- Q: Is there a difference between a textile knife and a chemical fiber knife and a fiberglass cutter?

- Fiber length, thickness, whiteness, gloss and other properties can be adjusted in the production process. And with excellent light fastness, wear resistant and easy to clean and no mildew, moth eaten etc.. Widely used in the manufacture of clothing fabric, cloth, conveyor belts, hoses, ropes, nets, electrical insulation, medical suture line, tire cord and parachute etc.. In general, polymers can be made into solutions or melts, extruded from the pores of the spinneret, and then solidified into fibers. The product can be without stop filament, cut to length of staple fibers or without cutting tow etc.. Chemical fiber product name, China Interim Provisions "all synthetic staple fiber" (e.g., nylon, polyester), short cellulose fiber are "fiber" (for example, viscose fiber, copper ammonia), filament in Matsuo Kachi "silk", or "Lun", "fiber", instead of "silk".

- Q: Which is better, glass fiber yarn mesh and high density nylon yarn net?

- (1) high tensile strength and small elongation (3%).Glass fiber yarn cutting(2) high elasticity and good rigidity.(3) the elongation within the elastic limit is large and the tensile strength is high, so the impact energy is large.(4) for inorganic fiber, with non flammable, chemical resistance.(5) water absorption is small.

- Q: What is mesh bag

- smearing 70 mm wide mesh at the mash bag part and the position close to door window and hole opening is the mesh uncontinued position, the mesh on the big faced wall needs to lap, and the pasted mesh should take the turning or covering protective measures of finished product, and the polymer mortar should be 2mm thick, and the mesh uncontinued position is easy to produce the stress and crack.

- Q: What is the purposes of epoxy resin mesh?

- Epoxy resin mesh is widely used in casting dry-type transformer coils and reactor coils with filler, which mainly uesed in the inner and outer cladding and layer insulation. It is connected closely with epoxy resin of casting coils to reinforce anti-cracking performance of casting coil. The function of mesh is same to the rebar of concrete, which can prevent cracking at the coil insulation layer due to the effect of hot and cold and huge electric power caused by sudden coil short circuit, greatly improving the overall mechanical coil strength. The mesh for inter-layer insulation of coils is a major insulation between the layers, which can improve the thoroughness and integration of resin casting, and prevent the coil internal faults and cracks, improved insulation and mechanical strength of the coil

Send your message to us

Mosaic Fiberglass Mesh - e-glass Fiberglass Wall Mesh for Architectural Material

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 3000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords