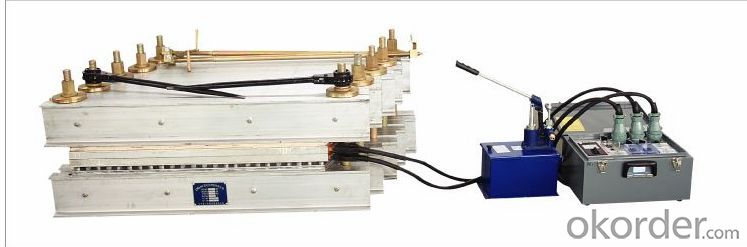

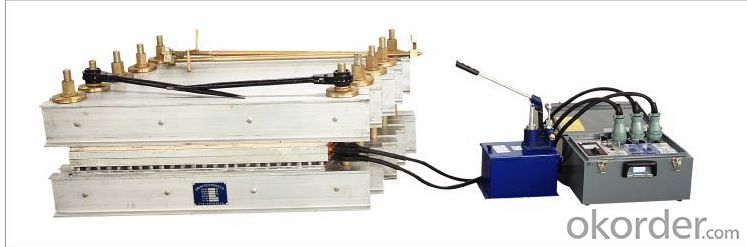

DW Electrical Conveyor Belt Vulcanizer

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

DW Electrical Conveyor Belt Vulcanizer

Details:Description

DW series of Electrical Conveyor Belt Vulcanizers (or vulcanizing press, hot vulcanizer machine) are special equipments for belt joint in conveyor machine field. The machine is made of light aluminum alloy materials, and with small size, light weight, ordinary three-phase current power supply, temperature uniformity of heating plate, uniform pressure (1.0 ~ 2.0 MPa) of water supply system. It is equipped with light Automatic Electronic Control Cabinet, which is connected with mainframe by integrative plug-in and multi-core cable. It's reliable and convenient to operate. At the same time, it has the merits of fast warming, uniform temperature, high thermal efficiency, etc. It is ideal belt joint equipment for rubber conveyor belt in the conveyor machine field. The quality of the belt joint will influence the working efficiency and service life of belts directly, especially for the long distance and high-strength conveyor belts. Therefore, CGLHJ vulcanizer is the necessary auxiliary equipment for belt conveyor.

Application

The vulcanizers are widely used in vulcanizing and belt joint of canvas, nylon, steel cord, conveyer belt at spot in metallurgy, mining, power plants, ports, building materials, chemical industry, etc, where are without sufficient explosive gases and the harmful gases which can corrupt metal. It can also be applied to the vulcanizing joints of belts of special features, such as anti-corrosion, thermal-protection, etc.

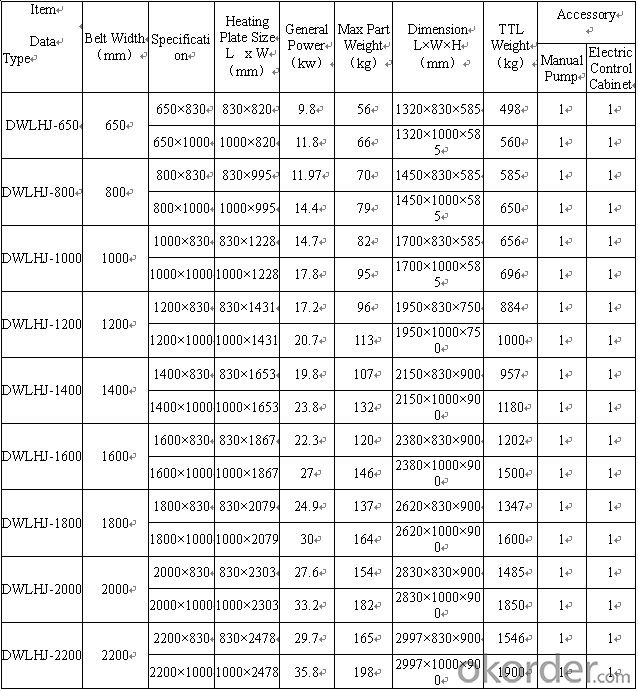

Technical Parameters

a) Vulcanization pressure: 1.0 ~ 2.0 Mpa;

b) Vulcanization temperature: 145 ℃;

c) Difference in surface temperature of vulcanized plate: ± 5 ℃;

d) Heating time (from normal temperature to 145 ℃): ≤30 mins;

e) Power supply voltage: 380V; 50Hz;

f) Output power of Electronic Control Cabinet: 36 KW;

g) Temperature adjustment range: 0 to 200 ℃;

h) Timing adjustment range: 0 to 99 min;

i) After the pressurization of 0.8 MPa, the gap between top and bottom heating plates is not more than 0.4 mm. Attached 1.

Vulcanizer Specification

- Q: What is rubber processing?

- From the 1950s onwards, on the basis of plastic processing, the development of the mold curing (see transfer molding) and pressure vulcanization (see injection molding). The two methods are characterized by the use of injection press, the compound directly into the mold for vulcanization, for the production of footwear and large quantities of model products.

Send your message to us

DW Electrical Conveyor Belt Vulcanizer

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot Searches

Related keywords