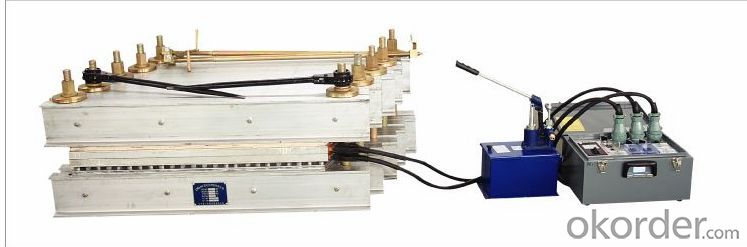

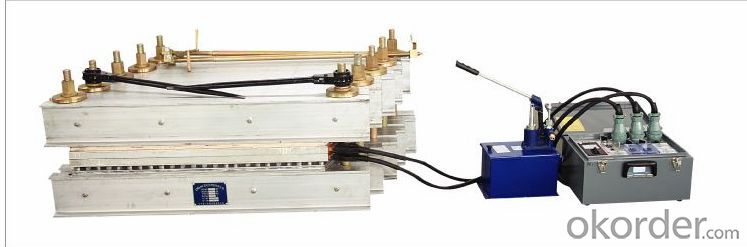

Electric conveyor belt vulcanizing press machine rubber vulcanizer

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description DW Series of Electrical Water Cooling Belt Vulcanizer (or vulcanizing press, hot vulcanizer machine) own small bulk, light in weight, ordinary three-phase current power supply, temperature uniformity of heating plate, uniform pressure (1.0 ~ 2.0 MPa) of water supply system. It is equipped with light automatic Electronic Control Cabinet, which is connected with mainframe by integrative plug-in and multi-core cable .It's reliable and convenient to operate. Presently the devices are widely used in vulcanizing and adhesive joint of canvas, nylon, steel cord, conveyer belt at spot in metallurgy, mining, power plants, ports, building materials, chemical industry around where are without sufficient explosive gases and the harmful gases which can corrupt metal. It can also be applied to the vulcanizing joints of belts of special features, such as anti-corrosion, thermal-protection, etc.

The device can cool heating plates quickly through water as long as there is ordinary water supply at the scene after vulcanization. It can greatly improve efficiency and enhance the quality of belt joints, generally cooling from the curing temperature to 60 ℃, 10 minutes, cooling water pressure ≥ 0.2 MPa.

Water Cooling Belt vulcanizer with light weight, can be moved by manpower easily. Please consider the facility of electricity and water before installation. Please put through the water sources with upper and lower heating plate, cooling water pipe by specialized water pipe, but not to discharge water for the time being. Then begin to maintain constant temperature until finish vulcanization, then open water supply at this time instill water into hot plates. When the temperature drops to preset technical value, discharging water and disassembling equipments are allowed, and the vulcanization is finished.

- Q: What are the rubber processing machinery companies?

- Jiangsu Rubber Processing Machinery Company, Jiangsu Rubber Processing Machinery Factory, Jiangsu Rubber Processing Machinery Yellow Pages

Send your message to us

Electric conveyor belt vulcanizing press machine rubber vulcanizer

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords