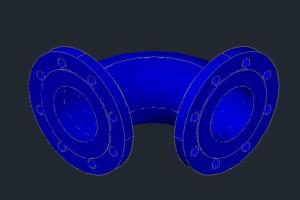

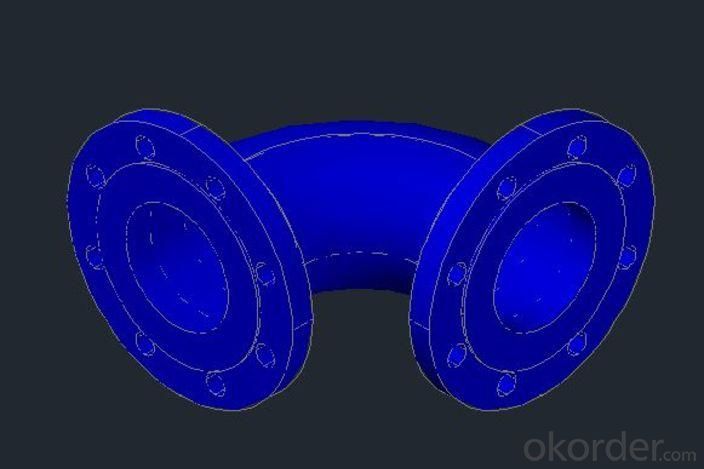

Ductile Iron Bend

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 50,000 Ton Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

90° Double Socket Bend

K12

Available in T Type and K Type;

Size: DN80-2000

Angle: 11.25, 22.5, 45, 90 DEG

We are involved in the manufacture and supply of the ductile iron Double Socket Bend. We manufacture these with the premium quality raw materials. Our Double Socket Bends ensure high durability and strength. Our range of Double Socket Bends caters to various industrial requirements. We offer these Double Socket Bend in different sizes and lengths in order to meet the various requirements of our esteemed clients.

Nominal Diameter DN | L | Mass(kg) | |

T Type | K Type | ||

80 | 100 | 8.6 | 12.0 |

100 | 120 | 11.5 | 15.6 |

150 | 170 | 20.5 | 27.5 |

200 | 220 | 33 | 40.0 |

250 | 270 | 48.5 | 55.5 |

300 | 320 | 68 | 81.5 |

350 | 370 | 83 | 105 |

400 | 420 | 143 | 134 |

450 | 470 | 156 | 166 |

500 | 520 | 183 | 202 |

600 | 620 | 273 | 290 |

700 | 720 | 455 | 408 |

800 | 820 | 605 | 544 |

900 | 920 | 813 | 720 |

1000 | 1020 | 1045 | 935 |

1200 | 1220 | 1508 | 1444 |

1400 | 1220 | 2419 | 1918 |

1600 | 1290 | 3382 | 2543 |

1800 | 1320 | 3616 | 3229 |

2000 | 1360 | 4516 | 4033 |

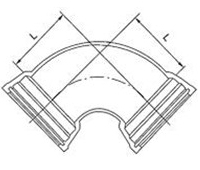

45° Double Socket Bend

K12

Available in T Type and K Type;

Size: DN80-2000

Angle: 11.25, 22.5, 45, 90 DEG

We are involved in the manufacture and supply of the ductile iron Double Socket Bend. We manufacture these with the premium quality raw materials. Our Double Socket Bends ensure high durability and strength. Our range of Double Socket Bends caters to various industrial requirements. We offer these Double Socket Bend in different sizes and lengths in order to meet the various requirements of our esteemed clients.

Nominal Diameter DN | L | Mass(kg) | |

T Type | K Type | ||

80 | 55 | 7.7 | 11.1 |

100 | 65 | 10.1 | 14.3 |

150 | 85 | 17.5 | 24.0 |

200 | 110 | 27 | 34.0 |

250 | 130 | 38.5 | 45.5 |

300 | 150 | 53 | 66.0 |

350 | 175 | 70 | 83.5 |

400 | 195 | 89 | 104 |

450 | 220 | 117 | 124 |

500 | 240 | 139 | 150 |

600 | 285 | 202 | 209 |

700 | 330 | 282 | 289 |

800 | 370 | 378 | 373 |

900 | 415 | 496 | 488 |

1000 | 460 | 635 | 628 |

1200 | 550 | 986 | 943 |

1400 | 515 | 1273 | 1223 |

1600 | 565 | 1740 | 1647 |

1800 | 610 | 2296 | 2166 |

2000 | 660 | 2970 | 2791 |

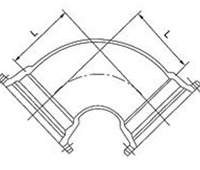

22.25° Double Socket Bend

K12

Available in T Type and K Type;

Size: DN80-2000

Angle: 11.25, 22.5, 45, 90 DEG

We are involved in the manufacture and supply of the ductile iron Double Socket Bend. We manufacture these with the premium quality raw materials. Our Double Socket Bends ensure high durability and strength. Our range of Double Socket Bends caters to various industrial requirements. We offer these Double Socket Bend in different sizes and lengths in order to meet the various requirements of our esteemed clients.

Nominal Diameter DN | L | Mass(kg) | |

T Type | K Type | ||

80 | 40 | 7.5 | 10.7 |

100 | 40 | 9.5 | 13.5 |

150 | 55 | 15.9 | 22.5 |

200 | 65 | 24 | 30.5 |

250 | 75 | 33.5 | 40.5 |

300 | 85 | 44.5 | 58.0 |

350 | 95 | 58 | 71.0 |

400 | 110 | 74 | 88.0 |

450 | 120 | 95.0 | 105 |

500 | 130 | 111 | 123 |

600 | 150 | 157 | 164 |

700 | 175 | 217 | 223 |

800 | 195 | 287 | 281 |

900 | 220 | 373 | 364 |

1000 | 240 | 470 | 463 |

1200 | 285 | 716 | 671 |

1400 | 260 | 933 | 882 |

1600 | 280 | 1259 | 1167 |

1800 | 305 | 1663 | 1533 |

2000 | 330 | 2114 | 1965 |

11.25° Double Socket Bend

K12

Available in T Type and K Type;

Size: DN80-2000

Angle: 11.25, 22.5, 45, 90 DEG

We are involved in the manufacture and supply of the ductile iron Double Socket Bend. We manufacture these with the premium quality raw materials. Our Double Socket Bends ensure high durability and strength. Our range of Double Socket Bends caters to various industrial requirements. We offer these Double Socket Bend in different sizes and lengths in order to meet the various requirements of our esteemed clients.

Nominal Diameter DN | L | Mass(kg) | |

T Type | K Type | ||

80 | 30 | 7.1 | 10.5 |

100 | 30 | 8.9 | 13.1 |

150 | 35 | 14.8 | 21.5 |

200 | 40 | 22 | 29.0 |

250 | 50 | 30.5 | 37.5 |

300 | 55 | 40.5 | 54.0 |

350 | 60 | 52 | 65.5 |

400 | 65 | 65 | 79.0 |

450 | 70 | 83.5 | 93.5 |

500 | 75 | 96 | 108 |

600 | 85 | 134 | 141 |

700 | 95 | 181 | 187 |

800 | 110 | 239 | 234 |

900 | 120 | 305 | 297 |

1000 | 130 | 381 | 375 |

1200 | 150 | 568 | 524 |

1400 | 130 | 747 | 697 |

1600 | 140 | 1007 | 914 |

1800 | 155 | 1331 | 1200 |

2000 | 165 | 1702 | 1522 |

Packaging & Delivery of Ductile Iron Bend

Packaging Detail: | wooden cases with plastic layer , wooden pallets with plastic layer , steel strip. |

Delivery Detail: | 30days after the order confirmed. |

Specifications of Ductile Iron Bend

MATERIAL:Ductile iron grade 500-7/ 450-10 in accordance with ISO 1083.

STANDARD: ISO 2531/EN 545/EN598

FLANGE: PN10, PN16 or PN25 drilling in accordance with ISO 7005-2/EN 1092-2.

COATING:

a. Zinc coating +bitumen painting;

b. Liquid epoxy painting;

c. Epoxy applied by FBE;

d. Other coating as your requirement

Test:Dimensions and testing in accordance with ISO 2531/EN 545 and 100% water pressure test.

Note: The gaskets, bolts & nuts are supplied respectively as your special requirement.

Usage:

It is a connection is commonly used in pipe installation with fitting, connect two of the same or different nominal diameter pipes.

- Q: Apart from the air-conditioning, the high-pressure pipe is not tight enough. What shall I do?

- Will affect the cooling effect, it is recommended to cut off the connector, and then use reaming device to expand after re installation. Charges will not be too high, dozens of blocks enough to be careful to be pit.

- Q: Fire alarm during heart surgery?

- It is a copy of the catalog I mentioned.

- Q: i use it on t-mobile. i can make calls, receive them and any text messages. but no picture or web browsing.

- Turbo works better with fuel injected engines. I would go with a supercharger for that engine if I was going to do it. A supercharger is easier and mostly bolt on anyways. A turbo has to have a lot of precise welding and requires a lot more time and money, and you will get better results with a supercharger.

- Q: Has anyone ran these tires before?How they work in snow/mud/ice/slush/off road?They are studdable so do i really have to have them studded? If I get them studded for the winter months, then in the spring is it possible to get the studs removed?

- No not at all, go ahead drive and park your burning car next to a fire hydrant. It just might be in the way of the firefighters trying to attach the hose to the hydrant so take caution to leave a little space. .good luck o_0

- Q: How far from a fire hydrant can you park in NJ?

- 1 Nominal Pipe Size [edited] - I knew I should have written a longer answer. nominal means exactly that - in name only. In order to make life easier for everybody, all 1 PVC pipe has the same outside diameter - 1.315. This makes it possible to interchange fittings and to switch pipe sizes when needed. The wall thickness does vary and so, for sch 40, 80, 120 in that order the inside diameter is: 1.029, .936, and .891. You might ask why anyone would mix sizes since either the size you choose can take the pressure or it can't. Often Schedule 80 is used to stiffness rather than pressure. Many sprinkler systems are sched 40 underground but switch to sched 80 for risers where the strength is important.

- Q: I like vaping in my house. But if I vape in a room with a smoke detector will I set it off? I usually vape in my living room which doesn't have a smoke detector. I also have an office in my house with a smoke detector, if I vape in there will I set it off?

- I can't speak to the girl tech as I deal in guy tech. :) Your mouse problem may be simpler than you think to solve. Turn the mouse upside down and undo the plate that holds the ball in. Clean out any accumulated dust and dirt that's in there and I think you'll find an amazing difference. I clean out my trackball mouse about once every 2 weeks and it has what look like little dust bunny pancakes around the parts that the ball moves. And if that doesn't work, you can pick up a trackball mouse for about $20 at most Office Depot type places. It will take you a few days to get used to but it's an option for you while you're waiting for wireless. Hope that helps and good luck!

- Q: How long the battery last on the phone? Give me your reviews

- They might make you retake it if you were out there for a long time, but a few minutes really won't mean anything. You teachers should have instructed you not to talk at all while outside. They might do an investigation, but I doubt they would make you retake it unless many people complained.

- Q: Need to heat the house and looking for a more responsible alternative. Current stove burns wood and coal. If I replace it with oil burning stove, will that pollute less? What about toxic fumes in the house? Or should I just go with burning wood in the 50-year old wood/coal stove?

- PLEASE take your daughter back to the doctors, hassle them if you have to!!! Last november I got a call from alder hey childrens hosp saying I had to take my son to them ASAP as he needed emergency surgery, because his bladder kidneys were so enlarged through blocked urine. I had my son back forward to the doctors at least 30 times b/c my son was bed wetting almost every night sometimes during the day, and he kept saying it was just a phase!!! It was only when my sons school go involved arranged an appointment with a paediatrician who in turn arranged my son to have bladder kidney scans. Just by chance a consultant from Alder Hey seen the scans thats when he called me, telling me to take Steven ASAP. What was happening was he wasnt passing urine properly (only drips at a time) and the rest of the urine was travelling back up to his bladder kidneys making them very inlarged. So when my son was relaxed sleeping the urine was trickling out, making him wet the bed. His kidneys were so damaged that he was weeks away from total kidney failure. I'm not trying to scare or frighten you, but PLEASE keep hassling your doc for scans etc.just in case!!! Hope things get sorted soon for you your daughter :D

- Q: I'm looking for a good pair of running tights without any bells and whistles. I'm not interested in any of this tech stuff, so no mesh behind the knees, no zippers on the calves, no reflective material, just basic black spandex. I'd like relatively heavy/sturdy spandex to keep me warm in 40F weather, and I might consider the fleece-lined type also.Could anyone suggest a brand and style? I'm a fan of Nike bottoms (their tops are awful!), so I looked at their website a bit and couldn't find anything as simple as what I want, so maybe I'm just missing something? I'd be happy with men's or women's styles.About 8 years ago, I bought some really simple men's Nike spandex and they were perfectafter seven years, they still felt like new. Unfortunately, I lost them and I'm trying to replace them. Thanks for any help!

- Screw it ask your parents. This looks like a quiz or test so y would I giv u the answers?

- Q: Must have all of theseleather seatsheated/cooling seatsSunroof/or the double onePush to start, or can live withoutKeyless entryawd (all wheel drive)V8 enginearound 300 horsepower at leastTriple climate control (one for the front passenger, one for the driver and one for the rear passengers)Blindspot detectorAuto-Parallel parkNoise cancellation sensors (outside noises or sounds cannot be heard in the cabin)Anti-Microbial vents (that means the bacteria and germs are sucked out when A/C or fan is used)Mahogany wood in the interior (lots of shine in polish)at least 10 airbagsAt least 240 mph as top speedat least 7 speed automatic transmission, preferably 8 speed auto transmissionWi-fi present always in interior (so rear and side passengers can use internet on laptop)

- if u use other than code approved fittings and pipe and have a fire etc your homeowners insurance will not cover u

1. Manufacturer Overview

| Location | Liaoning, China |

| Year Established | 1994 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | Mid East, Africa, Europe |

| Company Certifications | ISO 9001:2008; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 30% |

| No.of Employees in Trade Department | 500 People |

| Language Spoken: | English; Chinese; Spain; Alabic |

| b) Factory Information | |

| Factory Size: | Above 5,000 square meters |

| No. of Production Lines | 2 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Ductile Iron Bend

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 50,000 Ton Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords