ductile iron pipe k7 DN600 Socket Spigot pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1) The standard of pipe: ISO2531:1998, EN545:2006,K9 K8

2) Effective length: 6m/5.7m

3) Inner cement line: Portland cement lineas per ISO4179

4) Zinc coating: at least 130g/m2 as per ISO8179

5) Bitumen painting: at least 70μm as per ISO8179

6)With 102% quantity of NBR, SBR, or EPDM ring asper ISO4633

7) DN80-DN1200

8) Highstrength, lighter than grey iron, good corrosion resistance, no furring, smallflow resistance, easy fixing, long life tome about 100 yeas

9)Checked by automatic inspection equipment

10) Composition:

Chemical composition | |||

Chemical composition | Ductile Cast Iron Pipe (%) | Grey iron pipe (%) | Steel pipe (%) |

C | 3.5-4.0 | 3.2-3.8 | 0.1-0.2 |

Si | 1.9-2.6 | 1.4-2.2 | 0.15-0.4 |

Mn | 0.15-0.45 | 0.4-0.6 | 0.3-0.6 |

P | ≤0.06 | ≤0.3 | 0.02-0.03 |

S | ≤0.02 | ≤0.1 | 0.02-0.03 |

Mg | 0.03-0.06 |

|

|

11) Feature:

Mechanical properties | |||

| Ductile Cast Iron Pipe | Grey Iron Pipe | Steel Pipe |

Tensile Strength(Mpa) | ≥420 | 150-260 | ≥400 |

Yield Strength(Mpa) | ≥300 | No Confirmation | No Confirmation |

Bending Strength(Mpa) | ≥590 | 200-360 | ≥400 |

Elongation (%) | ≥10 | Neglected | ≥18 |

Brinell Hardness(HBS) | ≤230 | ≤230 | About 140 |

12) T type mechanical joint

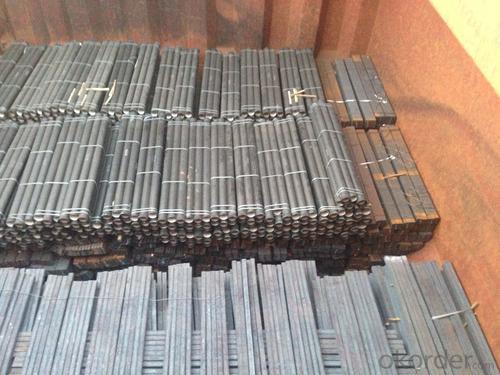

13) Packing: in bulk or container

PACKING: 1) Pipesare bundled together with the steel belt.

2) Wooden pieces are put between the pipes.

- Q: What are the different types of coatings available for ductile iron pipe?

- There are several different types of coatings available for ductile iron pipe, each with unique properties and advantages. 1. Cement Mortar Coating: This is a commonly used coating for ductile iron pipe. It involves applying a layer of cement mortar to the interior and exterior surfaces of the pipe. This coating provides protection against corrosion and abrasion, as well as improving the hydraulic efficiency of the pipe. 2. Polyethylene Encasement: Another popular coating for ductile iron pipe is polyethylene encasement. This involves wrapping the pipe with a layer of polyethylene material. This coating provides excellent corrosion resistance and is particularly effective in protecting against soil and water contaminants. 3. Fusion-Bonded Epoxy (FBE) Coating: FBE coating involves applying a layer of epoxy powder to the pipe surface, which is then heated to create a strong bond. This coating provides excellent corrosion resistance and is commonly used in aggressive environments such as wastewater treatment plants and chemical processing facilities. 4. Zinc Coating: Zinc coating, also known as galvanization, involves applying a layer of zinc to the surface of the ductile iron pipe. This coating provides excellent corrosion resistance and is often used in outdoor applications where the pipe is exposed to moisture and humidity. 5. Bituminous Coating: Bituminous coating is a black, tar-like substance that is applied to the surface of the pipe. It provides protection against corrosion and is commonly used in underground applications where the pipe is in contact with soil or water. 6. Polyurethane Coating: Polyurethane coatings provide excellent resistance to abrasion, impact, and chemical corrosion. They are often used in aggressive environments such as oil and gas pipelines. These are just a few examples of the different types of coatings available for ductile iron pipe. The choice of coating depends on factors such as the intended application, environmental conditions, and the level of corrosion protection required. It is important to consult with industry experts and adhere to relevant standards and specifications when selecting a coating for ductile iron pipe.

- Q: Are ductile iron pipes suitable for industrial water systems?

- Yes, ductile iron pipes are suitable for industrial water systems. Ductile iron pipes are known for their strength, durability, and corrosion resistance, making them an ideal choice for transporting water in industrial settings. They can withstand high-pressure and heavy-duty applications, making them suitable for conveying water in large-scale industrial facilities such as power plants, factories, and chemical plants. Additionally, ductile iron pipes have the ability to handle a wide range of temperatures, making them suitable for both hot and cold water systems. Their inherent flexibility allows for easy installation and maintenance, further adding to their suitability for industrial water systems. Overall, ductile iron pipes are a reliable and cost-effective solution for industrial water transportation needs.

- Q: What is the typical pressure rating of ductile iron pipes?

- The typical pressure rating of ductile iron pipes ranges from 150 to 350 PSI (pounds per square inch), depending on the diameter and class of the pipe.

- Q: What is the relationship between continuous cast iron pipe and ductile iron pipe?

- Continuous cast iron pipes are usually grey cast iron pipes. Its tensile strength and elongation are much lower than those of nodular cast iron. In chemical composition, grey cast iron has less carbon content than nodular cast iron. According to the organization, the graphite form of gray iron is flaky, and the graphite form in spheroidal graphite cast iron is spherical.

- Q: Can ductile iron pipe be used for bridge crossings?

- Yes, ductile iron pipe can be used for bridge crossings. Ductile iron pipe is known for its strength, durability, and flexibility, making it suitable for various applications, including bridge crossings. Its high tensile strength allows it to withstand heavy loads and vibrations, making it ideal for supporting bridges and handling the weight of traffic. Additionally, ductile iron pipe's flexibility allows it to absorb movements and deformations caused by temperature changes, settling, and other factors, reducing the risk of structural damage and ensuring the longevity of the bridge crossing. Furthermore, ductile iron pipe is resistant to corrosion, making it a reliable choice for bridge crossings where exposure to moisture, chemicals, and other corrosive elements is common. Overall, ductile iron pipe's properties make it a suitable and reliable material for bridge crossings.

- Q: Can ductile iron pipes be used for railway bridges?

- Yes, ductile iron pipes can be used for railway bridges. They are commonly used in bridge construction due to their high strength, durability, and resistance to corrosion. Additionally, ductile iron pipes can withstand heavy loads and provide excellent structural support, making them suitable for railway bridge applications.

- Q: What are the typical joint restraint requirements for ductile iron pipes under pressure?

- The typical joint restraint requirements for ductile iron pipes under pressure include the use of mechanical joint restraining devices such as bolts, gaskets, and thrust blocks. These restraints are necessary to prevent the pipes from separating or moving due to the internal pressure of the fluid being transported. Additionally, proper alignment and anchoring of the pipes are essential to ensure the integrity and stability of the pipeline system.

- Q: What is the expected thrust restraint method for ductile iron pipes?

- The expected thrust restraint method for ductile iron pipes is typically achieved through the use of thrust blocks or restraints, which are designed to counteract the forces generated by the fluid pressure within the pipeline. These blocks or restraints are typically made of concrete or other sturdy materials and are strategically placed at bends, tees, and other locations where changes in direction occur. They help to anchor the pipes and prevent them from moving or being displaced due to the thrust forces.

- Q: Are ductile iron pipes resistant to abrasion or wear?

- Yes, ductile iron pipes are highly resistant to abrasion or wear due to their inherent strength and durability.

- Q: Can ductile iron pipe be used for hydroelectric power generation?

- Yes, ductile iron pipe can be used for hydroelectric power generation. Ductile iron is a type of cast iron that exhibits high strength, durability, and excellent corrosion resistance. These properties make it suitable for various applications, including the construction of hydroelectric power generation systems. Ductile iron pipes can be used for water conveyance in hydroelectric power plants. They are commonly used for penstocks, which are large pipes that carry water from the reservoir to the turbines. Penstocks are typically subjected to high pressure and flow rates, and ductile iron pipes can withstand these conditions. Furthermore, ductile iron pipes are resistant to corrosion, which is crucial in hydroelectric power generation. The water used in the power generation process can be highly corrosive due to its composition and the presence of impurities. Ductile iron's corrosion resistance ensures that the pipes remain robust and durable over time, reducing maintenance and replacement costs. Additionally, ductile iron pipes can be easily joined using various methods such as flanged, mechanical, or push-on joints. This allows for efficient and reliable installation, ensuring the integrity of the water conveyance system in hydroelectric power plants. In summary, ductile iron pipe is a suitable choice for hydroelectric power generation due to its strength, durability, corrosion resistance, and ease of installation. Its use in penstocks and other water conveyance systems contributes to the efficient and reliable operation of hydroelectric power plants.

Send your message to us

ductile iron pipe k7 DN600 Socket Spigot pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords