Ductile Iron Pipe DN500-DN1000 ISO2531 In Bulk Vessel

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 300000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Ductile Iron Pipe Description :

1) Pipes confirm to ISO2531,K9 class,T type joint,6m long,with inside cements lining conform to ISO4179, outside Zinc

spraying(130g/m2) and bitumen coating(70μm) conform to ISO8179.

2) Pipe ends: Spigot and socket ends, with 100% SBR rubber gaskets accoding to ISO4633

3) we can do third party inspection according to customer's request.

2.Main Features of the Ductile Iron Pipe:

1. Material: Ductile iron grade 500-7/ 450-10 in accordance with ISO1083

2. Standard: ISO 2531, EN545, EN598, ANSI, AWWA

3. Certificate: ISO9001, ISO14001, SGS, NSF, WRAS

4. Test: In accordance with ISO 2531 / EN 545 / EN598 and 100% water pressure test

5. Length: 6m or cut into 5.6m, 5.7m, 5.8m

6. Internal Lining: Cement, conform to ISO4179

7. External coating: Zinc + Bitumen, conform to ISO8179

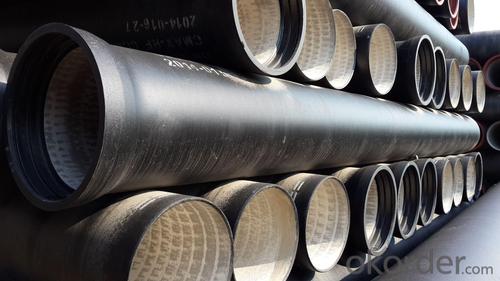

3.Ductile Iron Pipe Images:

4.Ductile Iron Pipe Specification:

Place of Origin: China (Mainland)

Model Number: DN80-1600

Length: 6M/5.7M/NEGOTIATED

Standard: ISO2531 / EN545

Application: Potable/Sewage Water

Diameter: DN80-1600

Shape: Round

Hardness: 230

Pipe Wall Thickness: standerd

Pull Strength: 420

Yield (≥ MPa): 300

5.FAQ:

We have organized several common questions for our clients,may help you sincerely:

1.Q: Why would you choose ductile iron pipe rather than other pipe materials?

A:The reasons are obvious for that not only ductile iron pipe possesses the inherent strength and flexibility of ductile

iron, combined with proven corrosion protection systems, but also the cost savings can be achieved from design to

installation and commissioning.

2.Q:Why can you guarantee the inner of pipes can’t be corroded?

A: High alumina cement mortar lining and sulphate-resistant cement mortar lining. These two special linings are applicable

to inner anti-corrosion for sewage pipes, improving resistance to erosion of the sewage components.

- Q: How is ductile iron pipe different from cast iron pipe?

- Ductile iron pipe and cast iron pipe are commonly used in plumbing and drainage applications, but they have differences in composition, strength, and flexibility. To begin with, ductile iron pipe is made from a different iron alloy than cast iron pipe. Ductile iron contains more carbon and silicon, which gives it increased strength and durability. On the other hand, cast iron pipe is made from gray iron, which has higher carbon content but lacks the flexibility of ductile iron. Moreover, ductile iron pipe is renowned for its superior strength and resistance to impact. It can withstand higher pressures and is less likely to crack or break under heavy loads or external forces. Cast iron pipe, although strong, is more brittle and prone to fractures and failures. Another significant distinction is the flexibility of ductile iron pipe. It possesses greater flexibility and can endure bending and deformation without fracturing. This flexibility facilitates easier installation, particularly in areas with uneven terrain or where ground movement may occur. In contrast, cast iron pipe is less flexible and more rigid, making it unsuitable for applications that require flexibility. Additionally, ductile iron pipe has a smoother interior surface compared to cast iron pipe. This smoothness reduces friction, enhances flow efficiency, and minimizes the accumulation of sediment and deposits within the pipe, resulting in improved water flow and reduced maintenance needs. In conclusion, ductile iron pipe sets itself apart from cast iron pipe due to its composition, strength, flexibility, and smooth interior surface. Ductile iron offers superior strength, impact resistance, and flexibility, making it the preferred choice in various plumbing and drainage applications.

- Q: How do ductile iron pipes compare to PVC pipes in terms of strength?

- Ductile iron pipes are generally considered to be stronger than PVC pipes. Ductile iron is a type of cast iron that has been treated with trace amounts of magnesium to give it enhanced strength, flexibility, and ductility. This makes ductile iron pipes highly resistant to cracking and breaking under pressure, making them suitable for a wide range of applications including water and wastewater transportation. On the other hand, PVC pipes are made from a type of plastic called polyvinyl chloride. While PVC pipes are relatively strong and durable, they are not as strong as ductile iron pipes. PVC pipes are more prone to cracking and breaking under high pressure or when exposed to extreme temperature fluctuations. They are often used for low-pressure applications such as irrigation and drainage systems. In terms of strength, ductile iron pipes have a higher tensile strength and can withstand higher internal and external pressures compared to PVC pipes. Ductile iron pipes also have a higher impact resistance, making them less susceptible to damage from external forces such as heavy machinery or accidental impacts. However, it is important to note that the choice between ductile iron and PVC pipes ultimately depends on the specific requirements of the project. Factors such as cost, installation ease, corrosion resistance, and the nature of the fluid being transported should all be considered when deciding between these two materials.

- Q: How do ductile iron pipes handle dynamic loads?

- Ductile iron pipes possess remarkable strength and durability, enabling them to effectively manage dynamic loads. These pipes exhibit a high resistance to bending and can endure the pressure and stress exerted on them when exposed to dynamic loads, such as water hammer or ground movement. The distinctive composition of ductile iron, which includes a small amount of carbon and the addition of magnesium, produces a structure that is both robust and flexible. This combination allows the pipes to flex when impacted by dynamic loads, rather than fracturing or breaking like other materials. Moreover, ductile iron pipes demonstrate a superior impact resistance, enabling them to absorb and distribute the energy generated by dynamic loads throughout their structure. This capability to dissipate energy effectively minimizes the risk of pipe failure and ensures the longevity of the pipeline system. Additionally, ductile iron pipes exhibit excellent stress distribution properties, ensuring that the load applied to the pipes is evenly dispersed along their length. This feature serves to prevent localized stress concentrations and reduces the likelihood of damage or failure. To summarize, ductile iron pipes are specially designed to handle dynamic loads with utmost efficiency. Their strength, flexibility, impact resistance, and stress distribution properties make them highly suitable for applications where dynamic loads are a concern, guaranteeing the reliability and longevity of the pipeline system.

- Q: Can ductile iron pipe be used for underground storage tank systems?

- Certainly, underground storage tank systems can utilize ductile iron pipe. Renowned for its robustness and potency, ductile iron pipe proves itself adaptable for diverse purposes, including underground storage tanks. Its exceptional tensile strength and immunity to corrosion render it a superb selection for confining and conveying liquids or gases in subterranean settings. Furthermore, ductile iron pipe exhibits remarkable resistance to external pressures and endures substantial burdens, establishing it as a dependable choice for underground storage tank systems.

- Q: Can ductile iron pipes be used for underground utilities?

- Underground utilities can indeed utilize ductile iron pipes. Renowned for their robustness, strength, and ability to withstand external pressure, ductile iron pipes prove to be a fitting option for subterranean applications demanding remarkable load-bearing capacity, such as utility installations. Furthermore, these pipes exhibit resistance to corrosion, a crucial attribute for underground environments that subject the pipes to dampness and soil conditions. Moreover, ductile iron pipes surpass alternative materials in terms of service life, thereby reducing the necessity for frequent replacements and maintenance. Consequently, ductile iron pipes find widespread application in underground utilities, encompassing water distribution, sewage systems, and gas pipelines.

- Q: Are ductile iron pipes resistant to chemicals?

- Generally, ductile iron pipes exhibit resistance to chemicals. Ductile iron, a variety of cast iron, is fortified with small amounts of magnesium to enhance its strength and ductility. This alloying process effectively heightens its ability to withstand corrosion and chemical attack. Ductile iron pipes have found extensive use in multiple applications, such as water supply, wastewater treatment, and industrial piping systems, where they may encounter a range of chemicals. Nevertheless, it is crucial to acknowledge that the resistance of ductile iron pipes to chemicals can vary based on the specific type and concentration of the chemical in question. Thus, it is advisable to seek guidance from the manufacturer or a qualified engineer to ascertain the suitability of ductile iron pipes for a particular chemical application.

- Q: Are ductile iron pipes resistant to hydrogen sulfide corrosion?

- Yes, ductile iron pipes are generally resistant to hydrogen sulfide corrosion. Ductile iron is a type of cast iron that has been treated with magnesium to create a more flexible and durable material. This treatment significantly enhances its resistance to corrosion, including corrosion caused by hydrogen sulfide. The magnesium in the ductile iron forms a protective layer on the surface, preventing the penetration of hydrogen sulfide and other corrosive agents. However, it is important to note that the resistance of ductile iron pipes to hydrogen sulfide corrosion can still be influenced by factors such as the concentration and duration of exposure to the corrosive environment. Therefore, proper maintenance, regular inspection, and appropriate protective measures should still be implemented to ensure the long-term durability and performance of ductile iron pipes in the presence of hydrogen sulfide.

- Q: Why does the cast iron pipe always run off when testing?

- The pipeline is installed, straight section of each pipe will be added pier, concrete pipe, elbow, three links should also have concrete pier, specific installation method according to GB Atlas 03SS515, and the straight pipe to soil, pipeline interface will be exposed, easy to check.

- Q: How does ductile iron pipe compare to steel pipe in terms of durability?

- Ductile iron pipe and steel pipe possess distinct characteristics, but when it comes to durability, ductile iron pipe holds several advantages over its steel counterpart. To begin with, ductile iron pipe boasts exceptional resistance to corrosion. It incorporates a protective layer of zinc or cement lining that safeguards it against rust and corrosion, enhancing its durability and reducing the likelihood of leaks or failures. Conversely, steel pipe is vulnerable to corrosion, particularly when exposed to moisture or specific chemicals. This susceptibility can lead to structural problems and diminish its overall durability. Furthermore, ductile iron pipe exhibits remarkable impact resistance. It can endure substantial loads and external pressures without cracking or breaking, rendering it suitable for applications in high-traffic areas or situations where the pipe may be subject to accidental impacts. Steel pipe, despite its strength, can be more brittle and prone to fractures under similar circumstances. Moreover, ductile iron pipe boasts a longer service life compared to steel pipe. With proper maintenance, it has been known to endure for over a century, making it a dependable and long-lasting choice for infrastructure projects. Steel pipe, although still durable, may necessitate more frequent inspections and maintenance to ensure its longevity. In conclusion, ductile iron pipe surpasses steel pipe in terms of durability due to its corrosion resistance, impact resistance, and extended service life. Nevertheless, the selection between the two ultimately depends on the specific application, budgetary constraints, and other project requirements.

- Q: Can the sealing ring of ductile iron pipe be reused?

- The sealing ring is hard to install and take off. I have been in this line for six years. I haven't seen it removed. The rubber ring itself is not expensive. It is not necessary to reuse it.

Send your message to us

Ductile Iron Pipe DN500-DN1000 ISO2531 In Bulk Vessel

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 300000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords