DUCTILE IRON PIPE DN125 K7

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 30000Tons m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

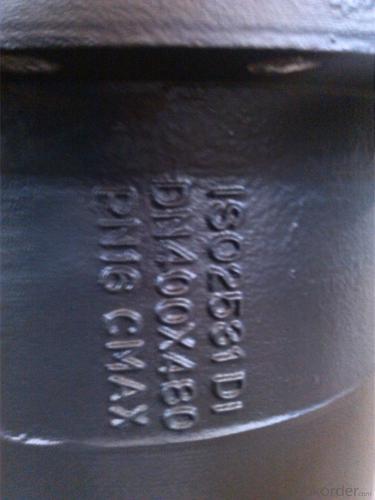

CNBM ductile iron pipe ranges from DN80-DN1600mm (T-Type, Class K9), effective length 6m, comply with ISO2531 Standard

Company Profile

CNBM International Corporation is the leading production base and renowned supplier of Ductile Iron Water Pipe systems of both potable and waste water in China. We are constantly looking to develop high quality products to ensure the longest service life and wonderful performance.

CNBM Pipelines regard quality as the essential factor leading to successful business. Every pipe is tested in accordance with BS EN545 (water application) or BS EN598 (sewer application). CNBM Pipelines products comply with and are tested according to the relevant European and International Standards. Our pipes are manufactured under the quality management system BS EN ISO 9001. After years of efforts, CNBM Pipelines has built up great reputation in terms of quality and service among customers worldwide

Product Introduction

CNBM ductile iron pipe ranges from DN80-DN1600mm (Tyton, T-Type, Class K7/K8/K9), effective length: 6m, complying with BS EN545/EN598/ISO2531/BS4772.

Specification& Payment terms

Internal lining: Pipes shall have an internal cement mortar lining in acc with ISO4179.

External coating: Pipes shall be externally coated with metallic zinc spray plus a further layer of resin painting to ISO8179.

Gasket: 100% SBR/NBR/EPDM gasket in accordance with ISO4633.

Packing: Pipes from DN100 to DN300 be bundled with steel belts, the others are in bulk.

Payment term: By 30% T/T advance payment + 70% Irrevocable L/C at sight.

Packing: In bulk vessel or in container.

- Q: How is ductile iron pipe installed?

- Ductile iron pipe is typically installed using a process called trenchless technology or open-cut method. In the trenchless technology approach, a hole is drilled into the ground and the ductile iron pipe is then pushed or pulled into the hole using hydraulic jacks or winches. This method minimizes disruptions to the surrounding environment and reduces the need for extensive excavation. In the open-cut method, a trench is excavated to the required depth and width for the ductile iron pipe. The trench is then prepared by removing any debris or obstructions and ensuring a stable base. The pipe is then lowered into the trench and aligned properly using laser or surveying equipment. After the pipe is positioned, joints are connected using a rubber gasket or mechanical joint. The joints are typically sealed to prevent leakage. Backfill material is then carefully placed around the pipe, ensuring proper compaction to provide stability and support. The backfill is typically done in layers to avoid excessive settlement. Once the installation is complete, the pipe is tested for leaks and pressure to ensure its integrity. This may involve hydrostatic testing, where the pipe is filled with water and monitored for any signs of leakage or pressure loss. Overall, the installation of ductile iron pipe requires careful planning, excavation, alignment, joint connection, backfilling, and testing. It is essential to follow industry standards and guidelines to ensure a successful and reliable installation that meets the required specifications.

- Q: What is the expected joint flexibility of ductile iron pipes?

- The expected joint flexibility of ductile iron pipes is typically high due to their inherent material properties. Ductile iron is known for its excellent ductility, which refers to its ability to deform without fracturing. This characteristic allows ductile iron pipes to withstand external loads, ground movement, and pressure fluctuations without major damage. The joints in ductile iron pipes are typically designed to provide additional flexibility and accommodate movement. The most common joint type used in ductile iron pipes is the push-on joint, which allows for angular deflection and axial movement. These joints consist of a rubber gasket that creates a watertight seal and allows for slight movement between pipe sections. The expected joint flexibility depends on various factors, including the pipe diameter, joint type, and installation methods. Generally, ductile iron pipes can accommodate angular deflection up to a certain degree, typically ranging from 5 to 10 degrees, depending on the joint design. Axial movement can also be accommodated to some extent, allowing for expansion and contraction of the pipe system. It is important to note that joint flexibility may vary depending on the specific manufacturer and product specifications. Therefore, it is recommended to consult the manufacturer's guidelines and specifications for the expected joint flexibility of a particular ductile iron pipe product.

- Q: What is the K9 standard pressure for ductile iron pipes?

- Ductile weakness: ductile cast iron pipes connected by human factors such as the operation level of responsibility, influence, construction not convenient. The advantages of PE PE PE pipe has good corrosion resistance and its anti inorganic performance than that of the metal pipe is much stronger in the buried without corrosion, construction convenient. Small diameter PE pipe in the price performance ratio is better than that of steel and ductile iron.PE tube have disadvantages: benzene, gasoline, carbon tetrachloride and other organic solvents have certain effect on pe. If the organic solvent is infiltrated into the polyethylene, the swelling will occur, and its physical properties will be decreased. Its pressure resistance and temperature resistance are poor.

- Q: What are the different joint types available for ductile iron pipe?

- The different joint types available for ductile iron pipe include push-on joints, mechanical joints, restrained joints, and flanged joints.

- Q: Are ductile iron pipes suitable for use in saltwater environments?

- Yes, ductile iron pipes are suitable for use in saltwater environments. Ductile iron is highly resistant to corrosion and can withstand the corrosive effects of saltwater, making it a reliable choice for piping systems in such environments.

- Q: There are several forms of flexible interfaces for Spigot Cast Iron Pipes

- At present, the flexible interfaces include slip type rubber ring interface, R rubber ring interface, flexible mechanical interface, A type and flexible mechanical interface, K type.1. slip in rubber ring interfaceRubber ring and pipe are supplied by supply factory. A rubber ring is installed before the socket in the working surface and no tower water supply equipment Jack working surface cleaned, the rubber ring embedded concave socket tip in the rubber ring, and the exposed surface and the socket of the working face, coated with lubricant has no influence on the quality of the rubber ring. The water supply equipment socket end chamfering and rubber ring even after contact with special tool socket socket will push, push people to mark depth should be set in advance, before the festival, before the two push interface depth and review has been.

- Q: What is the difference between flexible joint mechanism and seismic cast iron pipe DN100 and ductile iron pipe?

- Nodular cast iron has high strength and strong plasticity. The tensile strength of ductile iron is twice that of gray iron, and the yield strength even exceeds that of cast steel.

- Q: How are ductile iron pipes protected against erosion caused by high-velocity flow?

- Ductile iron pipes are protected against erosion caused by high-velocity flow through various methods. One common approach is to apply an internal lining to the pipe, which can be made of materials such as cement mortar or polyethylene. This lining provides a smooth surface that reduces the friction and turbulence of the flowing water, thus minimizing the erosion potential. Additionally, external coatings, such as bitumen or epoxy, can be applied to protect the outer surface of the pipe from erosion caused by external factors like soil movement or abrasive materials. Regular inspection and maintenance of the pipes also play a crucial role in identifying and addressing any erosion-related issues to ensure their long-term durability.

- Q: The plug connection DN800 ductile iron pipe has been installed. "Shall I think so?"

- Ductile iron pipes are defined as pipes made by casting more than 18 of casting molten iron by adding a spheroidal agent and then centrifugally centrifugally cast by a centrifugal nodular cast iron machineDuctile iron pipe ([span]Ductile Cast Iron Pipes), referred to as ball pipe, ductile iron pipe and ductile iron pipe etc..

- Q: Is the ambient temperature at minus 20 degrees better with grey cast iron or ductile iron?

- Ductile iron is good, its tensile properties are destined to withstand low temperatures, gray cast iron is a little bit worse.

Send your message to us

DUCTILE IRON PIPE DN125 K7

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 30000Tons m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords