DUCTILE IRON PIPE C DN 700

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 30000Tons m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

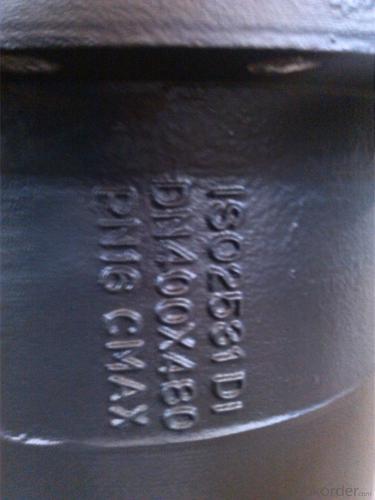

CNBM ductile iron pipe ranges from DN80-DN1600mm (T-Type, Class K9), effective length 6m, comply with ISO2531 Standard

Company Profile

CNBM International Corporation is the leading production base and renowned supplier of Ductile Iron Water Pipe systems of both potable and waste water in China. We are constantly looking to develop high quality products to ensure the longest service life and wonderful performance.

CNBM Pipelines regard quality as the essential factor leading to successful business. Every pipe is tested in accordance with BS EN545 (water application) or BS EN598 (sewer application). CNBM Pipelines products comply with and are tested according to the relevant European and International Standards. Our pipes are manufactured under the quality management system BS EN ISO 9001. After years of efforts, CNBM Pipelines has built up great reputation in terms of quality and service among customers worldwide

Product Introduction

CNBM ductile iron pipe ranges from DN80-DN1600mm (Tyton, T-Type, Class K7/K8/K9), effective length: 6m, complying with BS EN545/EN598/ISO2531/BS4772.

Specification& Payment terms

Internal lining: Pipes shall have an internal cement mortar lining in acc with ISO4179.

External coating: Pipes shall be externally coated with metallic zinc spray plus a further layer of resin painting to ISO8179.

Gasket: 100% SBR/NBR/EPDM gasket in accordance with ISO4633.

Packing: Pipes from DN100 to DN300 be bundled with steel belts, the others are in bulk.

Payment term: By 30% T/T advance payment + 70% Irrevocable L/C at sight.

Packing: In bulk vessel or in container.

- Q: Are ductile iron pipes suitable for oil and gas pipeline applications?

- Indeed, oil and gas pipeline applications can benefit greatly from the suitability of ductile iron pipes. With a multitude of properties that make them ideal for such uses, ductile iron pipes are a wise choice. First and foremost, the high tensile strength possessed by ductile iron pipes enables them to effectively handle the immense pressure and stress associated with oil and gas transmission. This ensures their ability to withstand the rigorous conditions and maintain their structural integrity over time. Additionally, ductile iron pipes exhibit exceptional resistance to corrosion. Given that oil and gas pipelines are exposed to various corrosive elements, such as water, chemicals, and salts, ductile iron pipes are equipped with a protective lining, typically composed of cement mortar or polyethylene. This lining effectively combats corrosion and prolongs the lifespan of the pipes. Moreover, ductile iron pipes boast impressive durability and longevity. With a service life typically spanning from 50 to 100 years, depending on specific conditions and maintenance practices, they prove to be a reliable choice for oil and gas pipeline applications. Consequently, the need for frequent replacements is reduced, resulting in minimized downtime. Furthermore, the flexibility inherent in ductile iron pipes allows them to endure ground movement and absorb shocks and vibrations. This flexibility is especially crucial in oil and gas pipeline applications, where the pipes must adapt to ever-changing terrain and environmental conditions. Lastly, ductile iron pipes offer a cost-effective alternative to other commonly used materials in oil and gas pipelines, such as steel. Striking a favorable balance between performance and price, they emerge as a practical choice for pipeline projects of varying scales. In summary, the combination of high tensile strength, corrosion resistance, durability, flexibility, and cost-effectiveness renders ductile iron pipes highly suitable for oil and gas pipeline applications.

- Q: What are the different types of ductile iron pipe joints?

- There are several different types of ductile iron pipe joints commonly used in various applications. These joints are designed to provide a strong and reliable connection between pipes, ensuring efficient fluid transfer and preventing leaks. Some of the most common types of ductile iron pipe joints include: 1. Push-on Joint: This type of joint is easy to install, as it does not require any special tools or equipment. The spigot end of one pipe is inserted into the bell end of another pipe, creating a tight seal. A rubber gasket is usually used to enhance the joint's resistance to leaks. 2. Mechanical Joint: Mechanical joints are commonly used in water and wastewater applications. They consist of a gland, a rubber gasket, and a follower gland. The pipe ends are pushed into the gland, and the follower gland is tightened, compressing the rubber gasket and creating a secure connection. 3. Restrained Joint: Restrained joints are specifically designed to withstand high internal and external forces such as water pressure or soil loadings. These joints typically use a rubber gasket and a restraining mechanism, such as a bolt or wedge, to prevent the pipe from moving or separating under stress. 4. Flanged Joint: Flanged joints are commonly used in large diameter pipes or applications requiring frequent disassembly. Each pipe end is equipped with a flange, which is then bolted together with the use of gaskets to create a strong connection. Flanged joints provide easy access for maintenance or repairs. 5. Welded Joint: Welded joints involve heating the pipe ends and fusing them together to form a permanent connection. This type of joint is commonly used in high-pressure applications where a reliable and leak-free connection is crucial. Welded joints require skilled labor and specialized equipment. It is important to choose the appropriate type of joint based on the specific application, pipe size, and operating conditions to ensure the integrity and longevity of the ductile iron pipe system. Consulting with a professional engineer or pipe manufacturer can help determine the most suitable joint for a particular project.

- Q: Are ductile iron pipes suitable for potable water distribution systems?

- Yes, ductile iron pipes are suitable for potable water distribution systems. Ductile iron pipes have excellent corrosion resistance, high strength, and durability, making them a reliable choice for transporting drinking water. They are also widely used in water infrastructure due to their ability to withstand high pressures and external loads.

- Q: What quota can be used for the installation of DN300 ductile iron pipes?

- Moreover, the ball tube is generally 5.5 meters long or 6 meters, if the length of the bridge is too long, to use the casing, the casing must also be fixed, and so on.

- Q: How do ductile iron pipes handle soil movement?

- Ductile iron pipes are renowned for their exceptional strength and durability, rendering them highly adept at managing soil movement. These pipes are engineered to withstand the external loads and pressures arising from soil settlement, ground shifting, or other environmental elements. A significant characteristic of ductile iron pipes lies in their flexibility. Unlike inflexible materials such as cast iron or concrete pipes, ductile iron pipes possess a certain degree of elasticity, enabling them to endure soil movement without succumbing to cracks or fractures. This flexibility empowers the pipes to absorb the stresses imposed by the soil, effectively preventing any substantial harm to the pipeline system. Furthermore, ductile iron pipes exhibit remarkable tensile strength, allowing them to resist the pulling forces that arise from soil movement. The pipes can endure the expansion and contraction of the surrounding soil, thereby diminishing the likelihood of pipe deformation or failure. Additionally, ductile iron pipes are frequently installed using proper bedding and backfilling techniques to further enhance their capacity to handle soil movement. Adequate bedding materials, such as crushed stone or sand, are utilized to deliver stable support to the pipes and distribute the external loads uniformly. This serves to minimize the impact of soil movement on the pipes and uphold their structural integrity. In conclusion, ductile iron pipes are purposefully designed to proficiently manage soil movement by virtue of their flexibility, high tensile strength, and appropriate installation methods. These pipes can effectively endure the stresses generated by soil settlement, ground shifting, or other soil-related factors, ensuring dependable and long-lasting performance in a variety of environmental conditions.

- Q: What are the different types of joints used with ductile iron pipe?

- The different types of joints commonly used with ductile iron pipe include push-on joints, mechanical joints, restrained joints, flanged joints, and welded joints. Each type of joint offers different benefits and is used depending on the specific requirements of the installation.

- Q: DN300 what's the price of the ductile iron pipe / the weight and the price of one meter?

- Ductile iron pipe is a kind of cast iron. It is an alloy of iron, carbon and silicon.

- Q: What is the expected thrust restraint method for ductile iron pipes?

- Typically, to achieve the expected thrust restraint for ductile iron pipes, mechanical joint restraints are employed. These restraints are designed to counteract the axial forces or thrust caused by the fluid pressure within the pipe. Thrust blocks, tie rods, and harness restraints are the most commonly used types of mechanical joint restraints for ductile iron pipes. Thrust blocks are concrete structures strategically placed around the pipe joints to resist the thrust forces. They are typically constructed at bends, tees, and other directional changes to prevent pipe movement. Tie rods, on the other hand, are another frequently used method of thrust restraint. These involve steel rods that are anchored to the pipe and securely fastened to an immovable structure to counter the thrust forces. Harness restraints, however, are constituted by a series of steel rods or cables that encircle the pipe and are anchored to the ground on both sides. These restraints effectively distribute the axial forces along the pipe's length, preventing movement and ensuring stability. The choice of a specific thrust restraint method for ductile iron pipes may vary depending on various factors such as pipe diameter, fluid pressure, soil conditions, and local regulations. It is vital to consult industry standards, engineering guidelines, and local authorities to determine the appropriate thrust restraint method for a particular application.

- Q: Are ductile iron pipes suitable for use in agricultural applications?

- Indeed, agricultural applications can benefit from the utilization of ductile iron pipes. Renowned for their remarkable strength and durability, these pipes are well-suited to endure the substantial loads and pressures frequently encountered in agricultural operations. Furthermore, their exceptional resistance to corrosion proves invaluable in agricultural settings where pipes may come into contact with chemicals or fertilizers. Additionally, the long lifespan of ductile iron pipes diminishes the necessity for frequent replacements, thereby minimizing maintenance expenses. In summary, the dependable choice of ductile iron pipes stems from their resilient nature and capacity to meet diverse agricultural demands.

- Q: Can ductile iron pipes be used for dam construction?

- Indeed, dam construction can utilize ductile iron pipes. Renowned for their robustness, longevity, and resistance to corrosion, these pipes prove apt for various purposes, including the construction of dams. They exhibit remarkable resilience under intense pressure, rendering them perfect for transporting water and other fluids throughout the dam's framework. Moreover, their capacity to withstand external forces and ground shifts establishes them as a dependable option for dam construction. Furthermore, the relative ease of installation and maintenance of ductile iron pipes enhances their appropriateness for dam construction endeavors.

Send your message to us

DUCTILE IRON PIPE C DN 700

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 30000Tons m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords