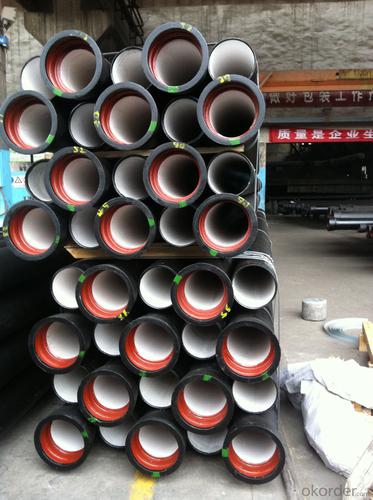

DUCTILE IRON PIPE AND PIPE FITTINGS K9 CLASS DN250

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 3000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Material : Ductile Cast Iron

Size Range : DN 80mm to DN 2000mm

Unit Effective Length : 6m or 5.7m

Manufacture Standard: ISO 2531:1998/ EN 545:2006/EN 598:2007

Annual capacity : 200,000 tons

Coating Exterior: Zinc 130g/m2 according to ISO 8179-1 and bitumen coating 70 microns.

Cement Interior: Portland Cement/ High Alumina Cement/ Sulphate Resisting Cement Lining according to ISO 4179

Special requirements on external coating and internal lining can be applied

We also provide accessories such as SBR/EPDM rubber gaskets, lubricant paste, pipe caps, PE sleeves, etc.

Additional Parts:

Each pipe is strictly inspected according to related standard to ensure permanently high performance.

Easy Installation at site and service free for life

Long Service Lifespan

Quotation will arrive you within 24hours once we get your inquiry.

We guarantee offering you a competitive price.

A copy of original inspection reports of pipes will be offered after shipment.

Photos of loading process will be sent to the customer after shipment effect.

We will follow-up the delivery progress after shipment effect and update to the customer on weekly basis.

- Q: What are the specifications for the installation of water ball iron pipes?

- Groove support: according to the groove soil, groundwater, slotted cross section, load conditions and other factors, the design requirements are firm and reliable, to prevent landslides, support, shall not impede the lower pipe and stable pipe.

- Q: How does ductile iron pipe resist internal corrosion?

- The resistance of ductile iron pipe to internal corrosion is achieved through a combination of distinct material properties and the use of protective coatings. To start, ductile iron, also known as nodular cast iron, is created by incorporating magnesium into molten iron, resulting in a graphite structure that is nodular or spherical in shape. This unique structure enhances the material's flexibility and elasticity, reducing the likelihood of cracking or fracturing when subjected to stress. Moreover, ductile iron possesses a dense microstructure with a high carbon content, serving as a barrier that prevents corrosive elements from penetrating the surface of the pipe. This inherent resistance to corrosion makes ductile iron pipe suitable for transporting various fluids, including water, sewage, and chemicals, without the risk of deterioration over time. Additionally, ductile iron pipes are often lined with protective coatings internally, further augmenting their resistance to corrosion. These coatings, such as cement mortar or epoxy, form a barrier between the pipe's surface and the fluid it carries, minimizing direct contact and decreasing the likelihood of corrosion. These linings are implemented during the manufacturing process, ensuring consistent and durable protection along the entire length of the pipe. In conclusion, ductile iron pipe successfully resists internal corrosion due to its material composition, including the nodular graphite structure and high carbon content, as well as the application of protective coatings. This combination of factors guarantees the longevity and dependability of ductile iron pipes in various applications, even in environments prone to corrosion.

- Q: Can the underground cast iron pipes be connected with clamps to form buttress?

- Best not to, because the use of clamp connection way to connect the poor integrity of the pipeline, the base treatment is not in place or uneven settlement, it is easy to produce deformation, resulting in pipe bending deformation, easily leaked from the junction.

- Q: What is the expected sound attenuation of ductile iron pipes?

- Several factors can affect the expected sound attenuation of ductile iron pipes. Generally, these pipes have good sound attenuation properties due to their dense construction and thick walls. The density of the material helps absorb and dampen sound waves, reducing noise transmission. Additionally, the thickness of the pipe walls adds an extra barrier for sound to pass through, contributing to sound attenuation. However, it's important to consider other factors that can influence the specific sound attenuation of ductile iron pipes. These factors include pipe diameter, wall thickness, installation method, and the surrounding environment. For example, larger diameter pipes may have slightly lower sound attenuation compared to smaller diameter pipes due to their increased surface area. Additionally, variations in wall thickness can affect the sound insulation properties. During installation, the presence of joints or fittings in the pipeline can create points where sound can transmit, reducing sound attenuation. Therefore, it is recommended to use proper installation techniques that minimize the use of joints and fittings to enhance sound attenuation. The surrounding environment also plays a role in sound attenuation. For instance, if the pipes are buried in soil, the composition and density of the soil can affect sound transmission properties. Moreover, the presence of other structures or materials nearby may influence the overall sound attenuation performance. To determine the specific expected sound attenuation of ductile iron pipes for a particular application, it is advisable to consult manufacturer specifications or seek assistance from acoustic engineering professionals. They can consider all relevant factors and conduct specific tests or simulations to provide accurate predictions.

- Q: What are the typical joint restraint requirements for ductile iron pipes in seismic zones?

- The typical joint restraint requirements for ductile iron pipes in seismic zones include using flexible mechanical joints, such as push-on joints or restrained joints. These joints are designed to allow movement and flexibility during seismic events, reducing the risk of pipe failure or damage. Additionally, proper anchoring and bracing of the pipes at critical locations, such as bends or changes in direction, is necessary to prevent excessive movement and ensure the integrity of the pipeline system.

- Q: Can centrifugal cast iron pipe be galvanized or coated with asphalt which is good for corrosion prevention?

- The centrifugal ductile iron pipe has the advantages of zinc coating and asphalt coating, and it is used in combination with two. By spraying zinc and epoxy coal tar coating of ductile iron pipe wall (or epoxy resin paint, polyurethane, etc.) wall using Portland cement (or epoxy powder, epoxy, polyurethane, ceramics etc.) wall coating can effectively active substances in soil and the formation of an insoluble zinc salt protection tube, the internal coating can inhibit corrosion of pipe body fluid medium.

- Q: How is ductile iron pipe protected against external corrosion?

- Ductile iron pipe is protected against external corrosion through a process called external coating. This involves applying a layer of protective coating, such as asphaltic or epoxy, on the outside surface of the pipe. The coating acts as a barrier, preventing moisture and corrosive substances from coming into contact with the iron, thus reducing the risk of corrosion. Additionally, cathodic protection methods, such as applying sacrificial anodes or using impressed current systems, may be employed to further enhance the corrosion resistance of the ductile iron pipe.

- Q: How are ductile iron pipes protected against external impact or loading?

- Ductile iron pipes undergo various methods and measures to safeguard them against external impact or loading, guaranteeing their durability and integrity. Several common approaches are employed to protect ductile iron pipes, including: 1. Adequate Thickness and Strength: Ductile iron pipes are designed with ample wall thickness and high strength to withstand external loads and impacts. This design feature ensures that the pipes can endure heavy loads without deforming or cracking. 2. Implementation of Coatings: Ductile iron pipes are typically coated with protective layers to create an additional barrier against external impact. These coatings may comprise cement mortar lining, polyethylene encasement, or epoxy coatings. They not only grant impact resistance but also safeguard against corrosion. 3. Utilization of Proper Bedding and Backfilling Techniques: Proper techniques for bedding and backfilling are crucial in protecting ductile iron pipes from external loads. The correct placement of pipes within suitable materials, such as compacted granular bedding and backfill, helps distribute external loads evenly and minimizes the risk of pipe damage. 4. Consideration of Trench Design: The design of the trench in which ductile iron pipes are installed plays a vital role in safeguarding them against external impact. The dimensions of the trench, slope stability, and proper compaction of the backfill are all taken into account to reduce the likelihood of damage caused by external loads. 5. Implementation of Effective Pipe Layout and Support: Appropriate pipe layout and support are essential for protecting ductile iron pipes from external impact. Sufficient support mechanisms, including thrust blocks, pipe anchors, and pipe restraints, are utilized to absorb and distribute external loads, preventing any damage to the pipes. 6. Installation of Protective Structures: In areas where the risk of external impact is higher, additional protective structures are installed to safeguard ductile iron pipes. These structures may include concrete encasements, bollards, or reinforced concrete slabs, which act as physical barriers against potential impacts. In conclusion, a combination of factors, including pipe strength, coatings, proper installation techniques, and support measures, work together to ensure the protection of ductile iron pipes against external impact or loading. These measures enhance the longevity and reliability of the pipes, guaranteeing efficient performance in various applications.

- Q: Are ductile iron pipes suitable for use in wastewater treatment plants?

- Ductile iron pipes are indeed a suitable option for utilization in wastewater treatment plants. This is due to the fact that ductile iron possesses immense strength and durability, enabling it to endure the harsh and corrosive environment commonly found in such facilities. Furthermore, it boasts exceptional resistance against abrasion, corrosion, and chemical assaults, rendering it a dependable choice for the conveyance of wastewater and the handling of diverse chemicals and substances encountered in the treatment process. Another advantage of ductile iron pipes lies in their high tensile strength, allowing them to withstand both high-pressure conditions and the weight of the surrounding soil. Moreover, these pipes are renowned for their flexibility, affording them protection against ground movement and settlement, thus ensuring long-lasting performance and dependability within wastewater treatment plants.

- Q: Which is good for water polo cast iron pipe steel pipe?

- Flexible seamless steel pipe is good toughness, good processing, better than ductile iron corrosion resistance, the price is slightly higher;

Send your message to us

DUCTILE IRON PIPE AND PIPE FITTINGS K9 CLASS DN250

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 3000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords