Ductile Iron Manhole Cover with Different Sizes for Construction and Mining

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 110 set

- Supply Capability:

- 4300 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

1) Designs: based on EN124 standard and according to customer's drawing or

samples.

2) Applications: water supply and drainage, fire engineering, natural

3) Inspection: in-house or the third party as per customer's request.

Advantages

Good compressive, bending and impact strength, anti-corrosion, not rust, long service life (at least 30 years).

The quality meets the same kinds cast ion manhole covers but the cost is 30% lower than.

Contain no metal and no recovery value, anti-theft.

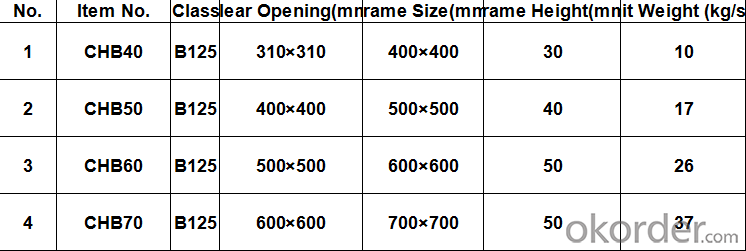

Specifications

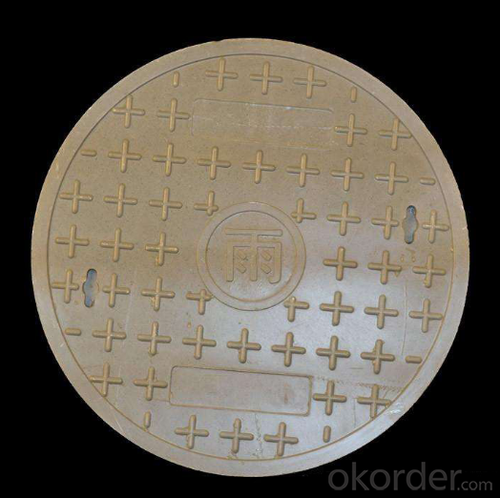

Double triangle ductile iron manhole cover

1.Standard:ISO 9001 EN124 D400

2.Service:OEM

3.High quality

4.Made of ductile

Pictures

FAQ

Why imported Composite Manhole cover/Grating fromChina?

1. Very competitive price, it will save you third or even half cost;

2.Good quality, don't worry much about the quality, actually, most of the building materials you buy from Miami, Dubai ,Italy, South Africa or your local market are imported from China. So why not buy direct from China. The key point is to find a reliable supplier who is honest and professional to take care of the quality and delivery time.

3.Chinahas full range of Manhole covers which Follow En124 for your market, like A15,B125,C250,D400.

- Q: What are the factors affecting the machining process of the casting material and structure?

- The impact on the machining is obvious, it should be the material and heat treatment of the castingCarbon steel parts should be treated by heat treatment (annealing) without special conditions. It can effectively prevent the uneven hardness and hard points. It is easy to turn.

- Q: Casting parts need to be subjected to the kind of heat treatment after the weldment is finished

- 1, gray cast iron: General graphite annealing, to be heat treatment annealing, surface hardening etc.; ductile iron can be various: annealing, normalizing, quenching and isothermal quenching, surface treatment, chemical heat treatment.2. Pouring liquid metal into the casting cavity which adapts to the shape of parts. After cooling and solidification, the casting method is called casting. Castings obtained by casting are called castings. Casting structure design: ensure the working performance and mechanical performance requirements, consider the technical requirements and performance of alloy casting casting casting structure, casting structure design is reasonable or not, the casting quality, productivity and cost has a great influence.3. Heat treatment is a metal hot working process in which the material is in solid state by means of heating, heat preservation and cooling to obtain desired microstructure and properties

- Q: Domestic large steel castings factory which is better, recommend!

- Do the casting manufacturer of large steel castings, Hunan Jinsha heavy industry science and technology limited company, heard that their professional only more than 1 tons of steel castings, anyway, 150T just big, the company won a lot of foundry industry patents should be good.

- Q: Why do cheap cars like stamping parts instead of casting parts?

- We usually say that the stamping is usually refers to the cold stamping parts, for example, a piece of iron, wants to turn it into a fast food dish, it must design a set of mold, mold is working face plate shape, the pressure plate mold, it becomes you want the dishes, this is the cold stamping die stamping is the direct use of metal materials.Automobile stamping parts are mainly classified according to process, and can be divided into two major parts: separation process and forming process.

- Q: Casting parts by shot blasting, spray painting, baking after the formation of very small rust spots, how to solve ah?

- The first process is very important. Shot blasting must be thorough. The solution is to wipe the surface of the paint with a release. Re shot

- Q: What is the reason for 304 stainless steel precision casting parts to be changed?

- Steel deformation control is one of the most common problems in the metal processing industry. Any process will occur. The casting is the largest deformation and the least fine. It is generally used to produce blank blanks

- Q: As shown, how do I achieve the tightness test of this product, and achieve industrial production? Seek expert advice.

- Precise and tight sealing of the surface to which the test piece is to be tested, equipped with an airtight test instrument, and an electrical control system. You can complete automated testing equipment

- Q: Where is the precision casting factory?

- The National Precision Casting Factory is generally distributed in Shandong, Ji'nan, Jiangsu, Wuxi, Changzhou, Zhejiang, Guangdong, Panyu, Dongguan.The above are only the main distribution, many of Shandong are made supercharger, and Guangdong to jewelry industry based.

- Q: Younger brother is to do casting valve, precision casting parts, the valve internal sand serious, but the appearance is very standard, this is why, for God answers, thank you!

- Increase the refractoriness and looseness of core sand

- Q: How to solve casting defect casting?

- Different defects, different solutions, some shortcomings, the current domestic level can not be resolved

Send your message to us

Ductile Iron Manhole Cover with Different Sizes for Construction and Mining

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 110 set

- Supply Capability:

- 4300 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches