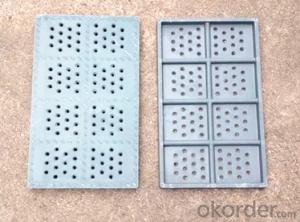

Ductile Iron Manhole Cover B125 for Industry in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

1) Designs: based on EN124 standard and according to customer's drawing or samples.

2) Color: black, Grey, green, blue and Marble , etc.

3) Applications: water supply and drainage, fire engineering, natural

4) Inspection: in-house or the third party as per customer's request.

Specification

| Item No. | Class | Clear Opening(mm) | Frame Size(mm) | Frame Height(mm) | Unit Weight (kg/set) |

| D80 | D400 | 700*700 | 800*800 | 100 | 92 |

| D70 | D400 | 600*600 | 703*703 | 100 | 77 |

Advantages:

Good compressive, bending and impact strength, anti-corrosion, not rust, long service life

(at least 30 years). The quality meets the same kinds cast ion manhole covers but the cost is 30% lower than. Contain no metal

and no recovery value, anti-theft.

Packaging & Shipping

Packaging: Details Pallet with bubble film, Carton or with pallet,

Delivery Detail: 8 days if your order is 20"container

Our Services

1. Sample is available for free.

2. OEM and ODM are welcome.

3. Free charge of design labels and cartons.

4. Our products: produced by the hydraulic Press. Meanwhile, a number of experienced workers do the strictly Quality control and have production tracking program.

5. Our price: we are the factory, we provide the most competitive price with good quality, and large order quantity will get big support by us!

6. Professional technical support with free charge.

7. After the cooperation: Any of your problem will be solved within 24 hours.

FAQ

1. How about your price?

A: As one of famous manufacturers of Ductile iron products inChina, Our prices are very favorable and competitive. The customers from all-over the world.

2. Can I request to change the form of packaging and transportation?

A: Yes, We can change the form of the packaging and transportation according to your requirement, but it maybe let your purchasing cost changed also.

- Q: Domestic large steel castings factory which is better, recommend!

- At least spend money on research and development, then the quality should be all right.

- Q: Why do cheap cars like stamping parts instead of casting parts?

- Separation process is also called blanking, the purpose is to make the stamping parts along a certain contour line from the sheet metal separation, at the same time guarantee the quality requirements of the separation section. Stamping is a highly efficient production methods, the use of compound die, especially the multi station progressive die stamping process can be completed in a multi machine, realized by belt uncoiling, leveling, punching, forming and finishing automatic production. High production efficiency, good working conditions, low production costs, can produce hundreds of parts per minute. The purpose of forming processes is to allow the sheet to undergo plastic deformation without breaking the billet and to make the desired shape and size. In actual production, a variety of processes are often applied to a workpiece. Blanking, bending, shearing, drawing, bulging, spinning, and straightening are the main types of stamping machines.

- Q: What kind of casting process is used for cast iron parts? And what are the cast steel parts adopted?

- Corundum sand: the main mineral composition is corundum alpha -Al2O3, used for investment casting, ceramic mold casting shell materials. The olivine sand: the main mineral composition of olivine (MgFe) 2SiO4, used in cast iron, non-ferrous alloy castings and high manganese steel casting molding sand and the core sand. Silica resources in nature resources, but suitable for casting with high SiO2 content of natural silica sand is not too much. Since 1951, China has carried out a general survey of the casting sand resources in the territory, but mainly limited to the main traffic lines and major industrial cities. Survey results show that Chinese can be used for natural silica sand casting is very rich in resources, a wide range of distribution. Inner Mongolia Zhelimumeng, natural silica sand reserves amounted to hundreds of millions of tons, the particle shape close to the circular, the content of SiO2 is about 90%. Fujian, Jinjiang Dongshan sea sand, the content of SiO2 is 94 to 98%, with a low volume of mud, are good natural silica sand. Are Duchang, Yongxiu Jiangxi County Xingzi, a large number of Quaternary lacustrine deposition of silica sand, the content of SiO2 is about 90%, low iron content, alkaline oxide less, uniform size, is a good lake sand. Guangzhou, Hunan and other places have abundant easily broken weathered sandstone, processing artificial silica sand, the content of SiO2 in more than 96%, can be used for the production of steel castings. Jiangsu Nanjing red sand, sandy mud pure, moderate, strong permeability, good viscosity, high silica content, less water, fine particles, pulls out the casting is smooth, stable quality, can be made of cast iron and non-ferrous metal parts of the sand and core sand

- Q: What is the reason for 304 stainless steel precision casting parts to be changed?

- 304 stainless steel is easier to change than ordinary steel. Because the 304 heat conductivity is lower than that of the low doped steel, the temperature is even more uneven, and 20% of the non ferrous elements also make the distribution of internal and external elements more uneven, hard and soft inside. Each of these two produces greater internal stresses, resulting in a variant.

- Q: The difference between cement sand castings, resin sand castings and vacuum casting parts

- Our country or international, in all casting production in 60 ~ 70% by sand casting is produced, of which about 70% is used in the production of clay sand. The main reason is that the cost of sand casting is low compared with other casting method, simple production process and short production cycle. So as the car engine cylinder body the cylinder head, crankshaft castings are produced using clay wet sand molding process. When the wet type can not meet the requirement to consider the use of clay sand table dry sand, dry sand mold or other sand.

- Q: What is the casting material?

- Kdl1588n said in detail, casting a lot of material, steel, iron, aluminum, copper, zinc, etc. can be, valuable, as well as gold and silver, the most common on cast steel and cast iron, cast aluminum and so on.

- Q: Which surface is coarser for cast iron or cast steel castings? Why?

- The surface of the steel is more rough, because the coating sand cast steel cast iron particles compared with graphite coating degree, the other one is to get a better air permeability and collapsibility of sand, the compaction degree is smaller than iron. Roughness mainly depends on the surface roughness on the surface of the sand.

- Q: When the blank is a casting, the margin is evenly distributed, how should rough machining?Please help friends from mechanical classes.There is another problem: in the NC milling plane contour machining, when the rough margin is large, how to deal with.Who can help in time, add 20 reward. Urgently!!

- Personal advice:Because of the large margin, your outline is easy to guarantee;So the key is to consider the assembly and aesthetics of the casting. You have to find the machining criteria;Rough the datum so that it can be machined;After the outline, turn back to the finishing line.If the casting requirement is not high, the benchmark can be directly processed; (not recommended)Over

- Q: Which master knows how the casting tolerances for malleable iron, gray iron and ductile iron should be chosen? Hurry up, thank youCan you provide a tolerance scale for castings, please?

- Our country has a national standard for casting tolerance levels. This national standard applies to you in malleable iron, grey cast iron, and ductile iron.

- Q: Is 316 casting better than 304 casting?

- The degree of difficulty in the process of casting depends mainly on the structure, precision requirements, and hardness of the casting.

Send your message to us

Ductile Iron Manhole Cover B125 for Industry in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches