Scotch 3850 Heavy Duty Packaging Tape - Double Sided Antistatic Tissue Tape for Multiple Use

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1800 m²

- Supply Capability:

- 120000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Product Description

Desc | Double Sided Tissue Tape Antistatic Multiple Use | |

Item No. | DT-22 | |

18G/Backing | 18g tissue | |

Thickness | 120mic | 140mic |

Tack | ≥20# | ≥24# |

180° Peeling | ≥16N/25mm | ≥20N/25mm |

Holding power | ≥8hrs | |

Temperature resistance | 60℃ | |

Color | Clear/Yellow | |

Usage | Embroidery | |

2.Packaging & Delivery

Packaging Details:

Polybag package or customized package

Jumbo roll: max length: 800m

Max width: 1260mm (usable 1240mm); 1040mm (usable 1020mm)

Slit roll: width/length available upon request

Delivery Detail: 10-25 working days after deposite receiptDelivery Detail:

Shipped in 15-25 working days after payment

3.Usage

1) adhere posters, photoes, public notes and envelopes

2) Fixing of ornament hook or signboard

3) Decoration

4) Shoe and leather industry

5) Computerized embroidery

4.Product Show

5.Company Information

CNBM International Corporation (CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.

CNBM is a professional adhesive tape supplier engaged in adhesive tape manufacturing , project technical support and adhesive design.

We specilized in Duct tape, Masking tape, Double sided tissue tape, PET tape, Foam tape, PVC tape, Warning tape, Fiberglass tape…Now we have exported our products to over 30 countries and regions like Europe ,South / North America ,Southeast Asia etc and gained customer's respect and continued businesses. Based on our good quality , reasonable price, good after-sale service, we enjoyed good reputation in the international market.

Warmly welcome your any inquiries or request ! You will be impressed by our superior quality, quick delivery date and attractive price. Contact us now!

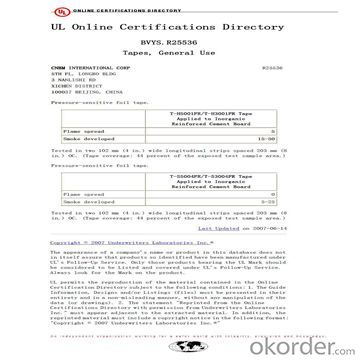

6.Certification and Factory

7.Why choose Us

• Good quality control in production process, ISO9001:2008,SGS.

• Excellent quality and Competitive price, OEM is available.

• Available in an extensive range of stock or custom size.

• The whole process from material to finished products can be traced.

8.FAQ:

Q1: May I have samples?

A: Yes, Free samples available and freight collect by DHL,FEDEX,TNT,UPS,SF,ect.

Q2: Are you manufacturer or trading company?

A: We are professional Manufacturer/factory .

Q3: Can I use our own designing?

A: Yes, size, color, printing, logo, paper core, carton box can be customized.

- Q: Are there any regulations or standards for packaging tape?

- Packaging tape is subject to regulations and standards in various countries, like the United States and European Union, to guarantee its safety and effectiveness in securing packages. These regulations encompass material composition, adhesive properties, thickness, tensile strength, and overall durability. Their purpose is to ensure that packaging tape meets specific quality and performance criteria, enabling it to withstand the challenges of transportation and handling without compromising the package's integrity. Furthermore, certain industries may have additional requirements for packaging tape, such as temperature resistance or tamper-evident features. Consequently, manufacturers and users of packaging tape must be aware of and comply with these regulations and standards to ensure the proper functioning and safety of their packaging materials.

- Q: Are there any special considerations when using packaging tape for fragile items?

- Yes, there are special considerations when using packaging tape for fragile items. It is recommended to use a high-quality and strong packaging tape specifically designed for fragile items. Additionally, it is important to apply multiple layers of tape to ensure secure and stable packaging. Bubble wrap or foam padding should also be used to provide extra protection and cushioning. Proper labeling indicating the fragile nature of the package is also crucial to alert handlers to exercise caution during handling and transportation.

- Q: Can packaging tape be used for sealing PVC pipes?

- Using packaging tape to seal PVC pipes is not recommended. PVC pipes need a specialized sealant that can bond with the PVC material and create a tight seal to prevent water leakage. Packaging tape is not suitable for this task and may not offer a reliable and durable seal. To ensure a proper and long-lasting seal, it is advised to use sealants or plumber's tape specifically designed for PVC pipes.

- Q: Is packaging tape safe to use on photographs?

- Packaging tape can be safely used on photographs when applied correctly and handled with care. Nevertheless, it is not advisable to use packaging tape on valuable or irreplaceable photographs. This is due to the potential risks of leaving residue or adhesive marks on the photos, which could lead to damage or deterioration of the image over time. It is recommended to opt for archival-quality materials that are specifically designed for preserving photographs, like acid-free photo corners or photo-safe adhesive. These alternatives guarantee the long-term safety and preservation of the photographs without causing any harm.

- Q: Can packaging tape be used for sealing packages with irregular shapes?

- Yes, packaging tape can be used for sealing packages with irregular shapes. Packaging tape is designed to be flexible and adhesive, making it suitable for securing packages of various shapes and sizes. Its strong adhesive properties enable it to stick to different surfaces, including irregular or uneven surfaces, ensuring that the package remains securely sealed during transit. Additionally, packaging tape is typically durable and tear-resistant, providing an extra layer of protection for the package. Therefore, whether the package has irregular shapes or not, packaging tape is an effective and reliable option for sealing it securely.

- Q: How do you choose the right packaging tape for your needs?

- When choosing the right packaging tape for your needs, it is important to consider a few key factors. First, assess the weight and durability of the items you will be packaging to determine the necessary strength of the tape. Additionally, consider the type of surface you will be sealing, as some tapes adhere better to certain materials. Furthermore, think about the environment in which your packages will be stored or shipped, as temperature and humidity can affect tape performance. Lastly, consider any special requirements you may have, such as tamper-evident or easy-to-tear tape. By considering these factors, you can select the most suitable packaging tape for your specific needs.

- Q: How does packaging tape perform on high-gloss surfaces?

- Packaging tape performs well on high-gloss surfaces. The adhesive used in packaging tape is designed to stick to a variety of materials, including glossy surfaces such as plastic, glass, or coated paper. The tape provides a strong bond, ensuring that the package remains securely sealed. It adheres firmly to the high-gloss surface, preventing the tape from peeling off or sliding around during transport or storage. Additionally, packaging tape is typically resistant to moisture, which further enhances its performance on glossy surfaces. Overall, packaging tape is a reliable choice for sealing packages on high-gloss surfaces, providing a secure and professional packaging solution.

- Q: What are the alternatives to packaging tape?

- Some alternatives to packaging tape include adhesive-free packaging solutions like interlocking flaps, self-sealing envelopes, or Velcro straps. Additionally, eco-friendly options like paper-based or biodegradable tapes can be used.

- Q: Can packaging tape be used for sealing construction materials or tools?

- Yes, packaging tape can be used for sealing construction materials or tools, but it may not provide as strong or durable of a seal as other specialized tapes designed specifically for construction purposes.

- Q: The tape is left on the door. The glue has dried for a long time. What chemicals can be used to remove it without damaging the paint?

- Chemicals or organic solvents are bound to damage the paint. If the glue is dry, it is recommended to put on a rubber, and generally go down.

Send your message to us

Scotch 3850 Heavy Duty Packaging Tape - Double Sided Antistatic Tissue Tape for Multiple Use

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1800 m²

- Supply Capability:

- 120000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches