Packaging Tape Brisbane - Double Sided Tissue Adhesive Multiple Use Tape Antistatic

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6800 m

- Supply Capability:

- 500000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Product Description

Desc | Double Sided Tissue Tape Antistatic Multiple Use | |

Item No. | DT-22 | |

18G/Backing | 18g tissue | |

Thickness | 120mic | 140mic |

Tack | ≥20# | ≥24# |

180° Peeling | ≥16N/25mm | ≥20N/25mm |

Holding power | ≥8hrs | |

Temperature resistance | 60℃ | |

Color | Clear/Yellow | |

Usage | Embroidery | |

2.Packaging & Delivery

Packaging Details:

Polybag package or customized package

Jumbo roll: max length: 800m

Max width: 1260mm (usable 1240mm); 1040mm (usable 1020mm)

Slit roll: width/length available upon request

Delivery Detail: 10-25 working days after deposite receiptDelivery Detail:

Shipped in 15-25 working days after payment

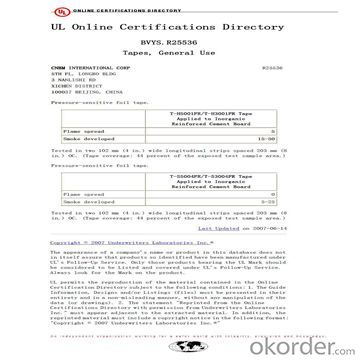

3.Certification and Factory

4.Our service

(1)24 hours prompt reply by email or telephone or messenger.

(2)Standard size have stock, immediately delivery once your purchase

(3)10 days delivery containers for out of stock

(4)Can combine containers with multiple insulation products for your different demand

(5)No quantity limit, from 1 rolls to full container, at your choose and demand!

5.FAQ:

1.Q:What's your payment terms?

A:L/C

2.Q:When could you send me the samples

A:2-3days

3.Q:Can I customize the strip length?

A: Yes

4.Q:Do you also sell other kinds led lights?

A:Yes, we also supply PVC tape, Warning tape, Fiberglass tape, Kraft adhesive tape, Aluminum Foil Tape, Foam double side adhesive tape etc.

- Q: How do I prevent packaging tape from tearing during removal?

- To avoid tearing when removing packaging tape, consider the following strategies: 1. Applying heat proves effective. Utilize a hairdryer or heat gun to warm the tape. The adhesive softens, facilitating tear-free removal. Exercise caution to prevent overheating or scorching. 2. A cutting tool, such as a utility knife or scissors, can be employed when tape removal becomes challenging. Carefully cut through the tape to prevent tearing, opting for smaller, manageable sections. 3. Adopt a patient and deliberate approach. Remove the tape gradually and at a low angle, exerting gentle pressure to avoid tearing. If met with resistance, pause and attempt different angles or apply heat to loosen the adhesive. 4. If the tape proves stubborn, seek assistance from a solvent like rubbing alcohol or adhesive remover. Apply a small amount to a cloth or cotton ball and gently rub the tape to dissolve the adhesive. Test the solvent on a discreet area first to ensure it doesn't damage the surface. 5. Make an informed tape selection. Opt for high-quality packaging tape with strong adhesion and good tensile strength. Reinforced or heavy-duty tapes are less prone to tearing. By employing these techniques cautiously, you can successfully remove packaging tape without tearing it.

- Q: Is packaging tape safe for use on photos or artwork?

- Yes, packaging tape is generally safe for use on photos or artwork, but it is not the ideal choice. Packaging tape is designed for securing boxes and packages, and it may not be archival quality, meaning it may not provide long-term protection for photos or artwork. Using packaging tape on photos or artwork can potentially damage the surface or leave residue when removed. It may also yellow or discolor over time, affecting the appearance of the artwork or photo. For preserving the integrity and longevity of photos or artwork, it is recommended to use acid-free archival tape specifically designed for this purpose. Archival tape is made with materials that are safe for use on delicate surfaces, and it is designed to be easily removable without causing any damage. In conclusion, while packaging tape can be used in a pinch, it is advisable to use archival tape to ensure the best protection for your valuable photos or artwork.

- Q: Is packaging tape safe to use on photographs?

- No, packaging tape is not safe to use on photographs as it can leave adhesive residue, damage the surface, or cause discoloration over time. It is recommended to use archival-quality photo-safe tapes or alternative methods for preserving and protecting photographs.

- Q: Is packaging tape resistant to oil or grease?

- Packaging tape is known for its general resistance to oil and grease. Its main purpose is to securely seal boxes and packages, offering protection to the contents during transportation. Usually, these tapes are manufactured using materials like polypropylene or PVC, which possess properties that make them resistant to different substances, including oil and grease. This resistance plays a significant role in preventing the tape from deteriorating or losing its adhesion when exposed to oils or greases commonly found in industrial or commercial environments. Nevertheless, it should be noted that the level of resistance may differ depending on the type and quality of the packaging tape employed.

- Q: Can packaging tape be used for sealing pet supplies or accessories?

- Yes, packaging tape can be used for sealing pet supplies or accessories. It provides a strong and secure seal, ensuring that the items are protected and contained during transportation or storage.

- Q: Can packaging tape be used for sealing metal boxes?

- Yes, packaging tape can be used for sealing metal boxes. Packaging tape is designed to provide a secure and durable seal on various surfaces, including metal. It offers a strong adhesive that can effectively stick to metal surfaces, ensuring that the box remains sealed during transportation or storage. However, it is important to choose a packaging tape that is suitable for heavy-duty applications and can withstand the weight and pressure that may be exerted on the metal box. Additionally, it is recommended to clean the metal surface before applying the tape to ensure proper adhesion.

- Q: Can packaging tape be used for sealing wooden furniture?

- Yes, packaging tape can be used for sealing wooden furniture. While it may not be the most conventional or aesthetically pleasing option, packaging tape can effectively seal gaps or cracks in wooden furniture, preventing dust, moisture, or insects from entering. However, it is important to note that packaging tape is not a long-term solution, as it may not provide the same level of durability or stability as other sealing methods specifically designed for wooden furniture, such as wood glue or epoxy. Therefore, it is recommended to use packaging tape as a temporary fix until a more appropriate sealing method can be applied.

- Q: Is packaging tape resistant to chemicals or solvents?

- Generally, chemicals and solvents do not pose a threat to packaging tape. Packaging tapes are typically composed of materials like polypropylene or polyvinyl chloride (PVC), which possess excellent chemical resistance. These materials are specifically engineered to endure exposure to a broad array of chemicals and solvents commonly found in industrial or commercial settings. Nevertheless, it is crucial to acknowledge that the resistance of packaging tape may differ depending on factors such as the brand, type, and quality of the tape. Consequently, it is advisable to review the product specifications or seek guidance from the manufacturer to obtain detailed information regarding the chemical resistance of a particular tape.

- Q: Is packaging tape safe to use on plastic outdoor furniture?

- Yes, packaging tape is safe to use on plastic outdoor furniture. It provides a secure and temporary solution for holding parts together or protecting certain areas during transportation or storage. However, it is important to note that the adhesive on the tape may leave residue on the furniture, especially if exposed to prolonged sunlight or extreme weather conditions. Therefore, it is recommended to remove the tape as soon as it is no longer needed to prevent any potential damage.

- Q: Is packaging tape safe to use on mirrors?

- Yes, packaging tape is safe to use on mirrors as it adheres well without causing any damage or leaving residue behind when removed.

Send your message to us

Packaging Tape Brisbane - Double Sided Tissue Adhesive Multiple Use Tape Antistatic

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6800 m

- Supply Capability:

- 500000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords