Packaging Tape - Double Sided Tissue Adhesive Antistatic Multiple Use Tape

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8500 m

- Supply Capability:

- 500000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Product Description

Desc | Double Sided Tissue Adhesive Antistatic Multiple Use Tape | |

Item No. | DT-22 | |

18G/Backing | 18g tissue | |

Thickness | 120mic | 140mic |

Tack | ≥20# | ≥24# |

180° Peeling | ≥16N/25mm | ≥20N/25mm |

Holding power | ≥8hrs | |

Temperature resistance | 60℃ | |

Color | Clear/Yellow | |

Usage | Embroidery | |

2.Packaging & Delivery

Packaging Details:

Polybag package or customized package

Jumbo roll: max length: 800m

Max width: 1260mm (usable 1240mm); 1040mm (usable 1020mm)

Slit roll: width/length available upon request

Delivery Detail: 10-25 working days after deposite receiptDelivery Detail:

Shipped in 15-25 working days after payment

3.Product Show

4.Company Information

CNBM International Cooperation is a subsidiary company of CNBM Group, which is one of the biggest state-owned company and Fortune 500 companies in the world.

All of our products are very affordable as a result of being produced in special economic development regions of China and we are more than happy to help you with the import/exportprocess too!

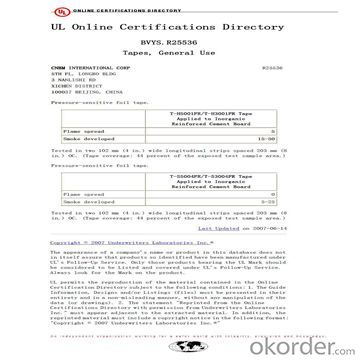

5.Certification and Factory

6.Our service

(1)24 hours prompt reply by email or telephone or messenger.

(2)Standard size have stock, immediately delivery once your purchase

(3)10 days delivery containers for out of stock

(4)Can combine containers with multiple insulation products for your different demand

(5)No quantity limit, from 1 rolls to full container, at your choose and demand!

- Q: Can packaging tape be used for sealing plastic bottles?

- Yes, packaging tape can be used for sealing plastic bottles.

- Q: Can packaging tape be used for shipping packages internationally?

- Yes, packaging tape can be used for shipping packages internationally. It is a common and reliable adhesive used to secure packages during transit, ensuring their safety and preventing any damage.

- Q: Can packaging tape be used for sealing plastic document holders?

- Yes, packaging tape can be used for sealing plastic document holders. Packaging tape is designed to provide a strong and secure seal on various surfaces, including plastic. It can effectively hold the plastic document holder closed, preventing any documents or contents from falling out. However, it is important to ensure that the tape is applied evenly and tightly to ensure a proper seal. Additionally, it is recommended to use clear packaging tape to avoid obstructing the view of the documents inside the holder.

- Q: Are there specific brands of packaging tape that are recommended?

- Certainly, there exist specific brands of packaging tape that are frequently suggested due to their quality and dependability. Noteworthy and highly respected brands encompass Scotch, Duck, 3M, Gorilla, and Uline. These particular brands are renowned for crafting packaging tapes that possess robust adhesive properties, exceptional durability, and the capability to effectively seal boxes and packages. Moreover, these brands frequently provide an array of options, including diverse widths, lengths, and types of tape (e.g., clear, colored, or reinforced), catering to various packaging needs. Nevertheless, it is always advisable to take into account the specific demands of your packaging task and peruse customer reviews prior to settling on a brand of packaging tape.

- Q: What are the considerations for using packaging tape on fragile items like ceramics?

- Several important considerations should be kept in mind when using packaging tape on fragile items such as ceramics. To begin with, it is crucial to carefully select the appropriate type of packaging tape. It is advisable to look for tape that is specifically designed for fragile items or delicate surfaces. This type of tape generally possesses features such as gentle adhesive and high tensile strength, which can help prevent damage or residue on the ceramics. Handling the ceramics with care during the application of the tape is also of great importance. It is important to avoid applying excessive pressure or force that could potentially result in cracking or breaking. Additionally, ensuring that the surface of the ceramics is clean before applying the tape is essential for proper adhesion. Consideration should also be given to the amount of tape that should be used. While it is necessary to adequately secure the ceramics, using an excessive amount of tape can add unnecessary weight and potentially harm the fragile item. It is advisable to use just enough tape to securely hold the ceramics in place without putting excessive strain on them. Furthermore, it is recommended to use additional protective materials in conjunction with the packaging tape. Bubble wrap, foam sheets, or packing peanuts can provide extra cushioning and protect the ceramics from potential impact or vibrations during transit. Lastly, it is crucial to label the package as fragile to ensure that handlers are aware of its delicate contents. This can help minimize the risk of mishandling and provide an extra layer of caution during transportation. In conclusion, when using packaging tape on fragile items like ceramics, it is important to consider factors such as selecting the appropriate tape, handling the ceramics with care, using the right amount of tape, employing additional protective materials, and clearly labeling the package as fragile. By taking these factors into account, the safe transportation of fragile ceramics can be ensured.

- Q: Does packaging tape have a specific adhesive strength?

- Yes, packaging tape typically has a specific adhesive strength which is designed to securely seal boxes and packages. The adhesive strength can vary depending on the brand and type of packaging tape being used.

- Q: How does packaging tape affect the weight of a package?

- Packaging tape itself does not significantly affect the weight of a package. However, the additional layer of packaging tape can slightly increase the weight due to its own weight and the adhesive used. Nevertheless, the impact on the overall weight of a package is typically negligible.

- Q: What materials are commonly used for packaging tape?

- Packaging tape is an essential tool used for securing and sealing packages for shipping, storage, or general handling. It is made from various materials, each with its own unique characteristics and advantages. The most commonly used materials for packaging tape include: 1. Polypropylene (PP): This is the most widely used material for packaging tape due to its affordability and versatility. It is a durable thermoplastic polymer that offers excellent resistance to moisture, chemicals, and UV radiation. PP tape is available in different thicknesses and can be transparent or colored. 2. Polyvinyl Chloride (PVC): PVC tape is known for its superior strength and durability. It is resistant to water, chemicals, and extreme temperatures, making it suitable for various environments. PVC tape is often used for heavy-duty applications or when extra security is required. 3. Polyester (PET): PET tape is made from a strong and durable synthetic polymer that offers excellent tensile strength and resistance to tearing. It is commonly used for heavy packages or in applications where high strength is crucial. PET tape is also resistant to UV radiation and moisture. 4. Paper: Paper-based packaging tape is an eco-friendly alternative to plastic tapes. It is made from renewable resources and is recyclable. While paper tape may not be as strong as plastic-based tapes, it still provides sufficient adhesion for lightweight or non-fragile packages. Additionally, paper tape can be easily torn by hand, which can be convenient for users. 5. Gummed Tape: Also known as water-activated tape or reinforced tape, gummed tape is made of kraft paper with starch-based adhesive on one side. It requires water to activate the adhesive, creating a strong bond that is tamper-evident and resistant to tampering. Gummed tape provides a secure seal and is often used for heavy packages or in industries where security is a top priority. Overall, the choice of packaging tape material depends on the specific requirements of the application, such as package weight, environmental conditions, and desired level of security.

- Q: Can packaging tape be used for sealing packages with sharp or pointed objects?

- Yes, packaging tape can be used for sealing packages with sharp or pointed objects. However, it is recommended to take additional precautions such as cushioning the sharp or pointed objects with protective material or placing them in a sturdy box to prevent the tape from getting damaged or punctured during transit.

- Q: What is the difference between acrylic and hot melt packaging tape?

- Sealing boxes and packages commonly involve the use of acrylic and hot melt packaging tapes, but they differ significantly in their adhesive properties and performance. Acrylic packaging tape boasts clarity and transparency, making it perfect for situations where package appearance matters. It also resists yellowing and aging, ensuring that it remains clear and does not become brittle over time. With a strong initial tack, acrylic tape adheres quickly to surfaces upon application. However, it may not perform as well in extreme temperatures, as its adhesive strength can diminish when exposed to high heat or cold conditions. In contrast, hot melt packaging tape consists of a synthetic rubber adhesive that is applied as a hot liquid. This tape offers superior adhesion and bond strength, making it suitable for heavy-duty or challenging packaging tasks. It excels in temperature resistance, maintaining its adhesive properties even in extreme conditions. Additionally, hot melt tape is known for its quick and effortless release, making it convenient for high-volume packaging operations. In conclusion, acrylic and hot melt packaging tapes are both effective for sealing boxes, but they have distinct advantages and disadvantages. Acrylic tape is ideal for situations prioritizing clarity, aging resistance, and initial tack. On the other hand, hot melt tape excels in adhesion strength, temperature resistance, and ease of use. Ultimately, the choice between the two depends on the specific requirements and conditions of the packaging task at hand.

Send your message to us

Packaging Tape - Double Sided Tissue Adhesive Antistatic Multiple Use Tape

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8500 m

- Supply Capability:

- 500000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords