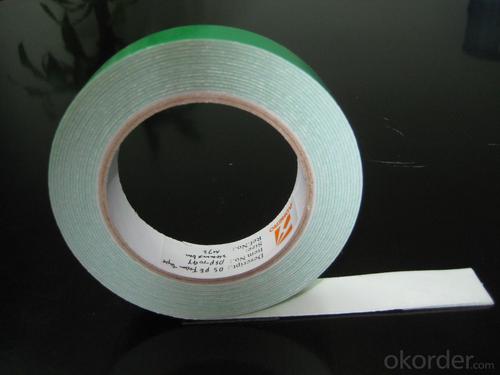

Clear Industrial Packaging Tape - Double Sided EVA Foam Tape with Acrylic Adhesive

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

CONSTRUCTION Of Double Sided Pothook Use EVA Foam Tape:

Backing: EVA Foam (Black/White)

Adhesive: Hot melt rubber adhesive.

Liner: White/Yellow

TYPICAL PHYSICAL PROPERTIES Of Double Sided Pothook Use EVA Foam Tape:

Total Thickness (adhesives + backing): 3 mm

Initial Tack: ≥12# (steel ball)

Peel Adhesion: more than 20 N/25mm (to steel)

Holding power(hrs): 50

Elongation(%): 100

Temperature resistance: 60 Degree Celsius

Sizes Of Double Sided Pothook Use EVA Foam Tape:

Jumbo Roll: 1.00 x 100m

Cut Roll: As per customer’s requirements

Application Of Double Sided Pothook Use EVA Foam Tape:

Holding of minor objects, bond between rough surfaces, reduce vibration & shock.

Bond & adhesion of various hooks, boards, mirrors.

Remarks Of Double Sided Pothook Use EVA Foam Tape:

1. The data above are typical results and subject to change without notice.

2. Tolerance: Weight and Thickness: ±10%; Width: ±3mm;

Length: Cut Roll & Log Roll ±0.3m, Jumbo Roll ±0.5%.

3. The products should be stored at room temperature and be kept away wet and/or heat source.

4. It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

5. The users should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for their special purpose and technique.

FAQ

Q 1:Do you have any MOQ of your adhesive tape ?

A:Yes, according to the size you need.

Q 2:What is the delivry time?

A:Sample time 7 days, 30 days for the mass production.

Q 3:Can we put our logo on the products?

A :Yes,welcome.

- Q: Is packaging tape resistant to moisture or humidity?

- Yes, packaging tape is generally resistant to moisture and humidity. It is designed to provide a secure seal and protect packages from water damage or humidity-related issues.

- Q: Is packaging tape heat resistant?

- Indeed, packaging tape typically exhibits heat resistance. The composition of most packaging tapes involves materials like polypropylene or acrylic, which possess elevated melting points and can endure extreme temperatures. Thanks to this heat resistance, packaging tape serves diverse purposes, such as sealing boxes and packages that may encounter heat during transportation or storage. Nevertheless, it is crucial to acknowledge that the heat resistance of packaging tape may fluctuate based on the tape's brand and quality. Hence, it is advisable to review the product specifications or seek guidance from the manufacturer to guarantee the tape's appropriateness for the desired utilization and temperature circumstances.

- Q: Is packaging tape safe for use on delicate surfaces or materials?

- Packaging tape, generally speaking, is not specifically formulated for delicate surfaces or materials. Although it may adhere well to most surfaces, there is a possibility of causing harm or leaving behind residue on delicate materials like paper, fabrics, or certain types of paint. To ensure the preservation of delicate surfaces or materials, it is advisable to utilize specialized tapes explicitly designed for delicate applications. These tapes are often known as "delicate surface tapes" or "low-tack tapes." They possess a gentle adhesive that can securely hold items together without causing any harm or leaving adhesive residue. Delicate surface tapes are commonly employed in the arts and crafts industry, particularly for delicate papers, scrapbooking, or as temporary adhesives for mounting artwork. Additionally, they prove useful in securing lightweight or fragile items during shipping or packaging. Hence, while packaging tape can be effective for general purposes, it is not recommended for use on delicate surfaces or materials. It is crucial to employ the appropriate tape for the specific task at hand in order to safeguard delicate surfaces and prevent any potential damage or residue.

- Q: Can packaging tape be used for mailing packages?

- Absolutely, packaging tape is perfect for mailing packages. Its main purpose is to securely seal packages and guarantee their integrity while in transit. This type of tape is known for its strength and durability, which makes it the ideal choice for securing boxes, envelopes, or any other packaging material. It is widely utilized in shipping and mailing scenarios and comes in different sizes and strengths to adapt to various package dimensions and weights. Regardless of whether you are sending a tiny envelope or a substantial box, packaging tape is an indispensable tool to guarantee the proper sealing and protection of your package throughout the mailing process.

- Q: Does packaging tape come in different lengths for convenience?

- Yes, packaging tape does come in different lengths for convenience. Packaging tape is available in various lengths to meet the needs of different packaging tasks. The most common lengths of packaging tape are 55 yards (50 meters) and 110 yards (100 meters). These lengths are designed to cater to different packaging needs and ensure that there is enough tape to securely seal multiple packages without running out. Additionally, the availability of different lengths allows for flexibility in choosing the most suitable amount of tape for specific packaging requirements, ensuring convenience and cost-effectiveness.

- Q: Can packaging tape be used for sealing camping or outdoor gear?

- Yes, packaging tape can be used for sealing camping or outdoor gear. It is strong and durable, providing a temporary seal for items such as tents, sleeping bags, and backpacks. However, for longer-term or more permanent seals, it is recommended to use specialized outdoor repair tapes or adhesives designed for outdoor gear.

- Q: How do I prevent packaging tape from sticking to itself?

- To prevent packaging tape from sticking to itself, you can try folding over a small portion of tape at the end, creating a tab that will make it easier to peel off when needed. Additionally, you can use a dispenser or a cutting tool to cleanly cut the tape, minimizing the chances of it sticking to itself.

- Q: Is packaging tape safe to use on plastic cutting boards?

- Packaging tape is indeed a safe option for plastic cutting boards. Its design enables it to stick to various surfaces, including plastic, without causing any harm or damage. It is commonly utilized for sealing packages and boxes, and does not contain any hazardous chemicals or substances that could jeopardize the plastic cutting board or the food being prepared on it. Nevertheless, it is crucial to acknowledge that utilizing packaging tape on a cutting board is not advised for reasons related to food safety. To avoid potential contamination, it is recommended to employ food-grade materials like food-safe adhesive tape or rubber bands to secure plastic cutting boards.

- Q: Is packaging tape safe to use on painted surfaces?

- Packaging tape is generally considered safe for use on painted surfaces, but there are a few factors that need to be taken into account. Firstly, it is crucial to make sure that the paint has completely dried before applying any tape. This usually takes about 30 days, depending on the type of paint used. Applying tape to fresh or wet paint can result in damage when the tape is removed. Secondly, the type of tape utilized can also impact the outcome. Most packaging tapes are designed to be easily removable without leaving any residue or causing harm to surfaces. However, there are some low-quality tapes or those with strong adhesives that may leave sticky residue or even strip off the paint upon removal. It is advisable to opt for high-quality packaging tape that is explicitly labeled as safe for painted surfaces. To err on the side of caution, it is always wise to conduct a test on a small and inconspicuous area of the painted surface before applying the tape extensively. This will help ensure that the tape does not cause any damage or leave any residue behind. If there are any concerns, it is recommended to consult the manufacturer's instructions or seek professional advice. In conclusion, when used correctly and on fully dried paint, packaging tape should be safe for use on painted surfaces. However, it is vital to exercise caution and select the appropriate tape to prevent any potential damage.

- Q: Does packaging tape have any specific certifications or standards?

- Yes, packaging tape can have specific certifications or standards. There are various organizations and standards that set guidelines for packaging materials, including packaging tape. One of the most common certifications for packaging tape is the International Organization for Standardization (ISO) certification. ISO sets standards for quality management systems, and packaging tape can be certified under ISO 9001:2015, which ensures that the product meets certain quality criteria. In addition to ISO certification, packaging tape can also adhere to specific industry standards such as ASTM International standards or European Union directives. ASTM International develops and publishes technical standards for a wide range of materials, including packaging tape. These standards ensure that the tape meets specific requirements related to strength, adhesion, and durability. Furthermore, some packaging tapes may have certifications related to their environmental impact. For example, certain tapes may be certified as recyclable, biodegradable, or made from sustainable materials. These certifications can be obtained from organizations like the Forest Stewardship Council (FSC) or the Sustainable Forestry Initiative (SFI), which promote responsible forestry practices. It is important to note that not all packaging tapes will have certifications or adhere to specific standards. However, if a packaging tape does have certifications or complies with certain standards, it signifies that the product meets certain quality, performance, or environmental criteria.

Send your message to us

Clear Industrial Packaging Tape - Double Sided EVA Foam Tape with Acrylic Adhesive

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords