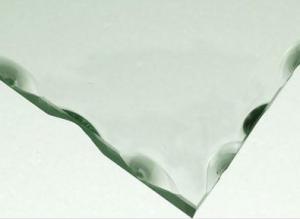

Double Shell Edge

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 Square Meter/Square Meters m²

- Supply Capability:

- 300,000 Square Meter/Square Meters per Year m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Model Number:CTG-281

Function:Decorative Glass

Shape:Flat

Structure:Solid

Technique:Clear Glass,Tempered Glass

Type:Float Glass,Tempered Glass

Application:Furniture Glass

Size:2440*6600mm

Thickness:3mm,4mm,5mm,6mm,8mm,10mm,12mm,15mm,19mm,22mm,25mm

Composition:Toughened Glass

Packaging & Delivery of Double Shell Edge

Packaging Details:wooden crades

Delivery Detail:25days

Specifications of Double Shell Edge

Double shell edgeInspection: AS/NZS 2208: 1996,EN12150Thickness: 3-15mmSafer than ordinary glassGood appearance

Double shell edge

Tempered glass is to heat glass up to 700 degrees and then rapidly cool down, according to different degrees;

Double shell edge is a kind of special edge, which used for furniture, we can process different edges by customer's requested. Besides OG edge polished glass, other commen edge are: flat polishd edge, pencil polished edge, also call bull nose polished edge, round polshed edge, C polished edge. circle polished edge, bevel polished edge, covex edge, miter edge and so on.

Features of Double Shell Edge:

1. Tempered glass is a kind of safe glass and the fragment of which does no harm to people.

2. it’s 4-5 times safer and harder than ordinary annealed glass.

3. Special logo and pattern can be printed on tempered glass.

4. Outstanding performance in resisting thermal stress and wind-load.

5. Bear sudden temperature change of 220 centigrade degree

Specification of Double Shell Edge

Thickness: 4mm-25mmMaximum measurement: 8800mmX2440mmMinimum measurement: 250mmX100mmAnnual Productivity: 300,000M2

Inspection: AN/NZS 2208:1996, BS6206, EN12150

Application of Double Shell Edge

According to building laws, the place must use safety glass: windows and another parts of building; glass railings and escalator railings; the windows of cars and ships; glass tabletop and display shelf; indoor decoration and furniture etc.

Our characteristics of Double Shell Edge

Imported equipment of high quality and high value can make the surface of the tempered glass meet the needs of the strict requirement for architecture, furniture, Electron industry.

Optional Information of Double Shell Edge

- Payment: T/T or L/C

- Delivery: 20DAYS

- Origin: CN

- Minimum Order: 20'FT

- Packaging: Wooden crate or Carton

- Inspection: AN/NZS 2208: 1996, BS, EN12150

- Samples: Free

- Q: Is acrylic organic glass?Which is more expensive, acrylic or plexiglass?

- Acrylic is English Acrylics, Acrylics is acrylic acid (ester) and methacrylic acid (ester) general class of chemicals. People often say that the acrylic sheet is polymethyl methacrylate (PMMA) plate, which is composed of methyl methacrylate monomer (MMA) polymerization.

- Q: The main chemical constituents of ordinary glass

- The raw materials for making ordinary glass are soda ash, limestone and quartzThe composition of common glass chemical oxides (Na2O, CaO, 6SiO2), the main component is silica

- Q: What is glass fiber reinforced nylon?

- Add the mechanical properties of glass fiber, toughening agent [1] blends in nylon. The results showed that with the increase of fiber content, the tensile strength, the flexural strength of the composites is greatly improved, the impact strength is more complicated, toughening agent is added, toughness is greatly improved. The material adding glass 30% ~ 35%. 8% to 12% of the toughening materials, the best comprehensive mechanical properties.

- Q: The main reasons for failure of air glass are outlined

- The typical phenomenon of the failure of insulating glass products is that the condensation and water inflow in the insulating glass interlayer affect not only the appearance of the whole glass, but also the thermal performance of the whole glass.

- Q: Glass fiber reinforced plastic (FRP) is a new type of composite material. What is the raw material?

- Glass fiber reinforced plastics have the advantage of high strength:Ordinary glass is a brittle material of low strength. If fused glass is made into very fine glass fiber, its properties change greatly. Glass fibers are soft and can even be woven into cloth. At the same time, the thinner the glass fiber, the higher its strength. The strength of GRP can be compared to that of reinforced concrete. In reinforced concrete, the main force to bear external force is steel, but concrete is indispensable, it will bond the steel as a whole, not only gives the building components in a definite shape, but also increase the strength. In glass fiber reinforced plastics, glass acts as reinforcing steel, while bakelite acts as concrete. The combination of the two makes glass fiber steel an amazing strength.Glass fiber reinforced plastics not only has high strength, but also has excellent corrosion resistance, thus becoming an important corrosion-resistant material. Lead, once a corrosion resistant metal material, is resistant to sulfuric acid, which is highly corrosive. The reason is that the formation of Pb and concentrated sulfuric acid to dissolve lead sulfate, become a kind of protective film on the surface of the dense metallic lead, so the chemical reaction kettle and lead lined pipes used, can also be used for enamel liner. If fiberglass is used, the corrosion resistance meets the requirements. Also used for glass steel valves, pumps, fans, suitable for the transport of corrosive liquid tank car and train tanker, waste acid waste liquid pool in the village and a large area in the storage tank, chemical plant production storage corrosive liquid corrosion on the ground. The corrosion of petroleum is also very strong, and glass fiber reinforced plastics can be used instead of steel pipes to make oil pipelines and oil trucks, which greatly saves the steel.

- Q: The shell of glass steel electric cars will not be on the poor out of the glass Sizha?

- There are 2 kinds of process for making automobile shell with glass fiber reinforced plastic, 1. hand paste forming process and 2. pressing processThe choice of raw materials is reasonable, according to the operating procedures, the product is not defective, will not appear exposed fiber, it will not cause skin itchingA small number of unscrupulous manufacturers, technical level is low, Jerry built products must be betterYou can spray a layer of resin or a layer of dry adhesive tape on the exposed surface of the fiber when you encounter inferior products

- Q: What happens when toughened glass breaks?

- A ton of glass raw materials, at least 3-4 of nickel sulfide crystals, the number of tons of glass made of pieces of a square size glass, which will have 3-4 to explode, which is self depicting the image of.

- Q: There are several ways of heating the industrial drying tunnel furnace and are different from each other?

- The stainless steel heating tube heats the fluid by forced convection. The material is made of stainless steel is in a head with a heater pump to pump fluid into the heating chamber, after heating in the heater, another head out, is a kind of forced circulation pump through a heating method, compared with the traditional heating methods, energy saving, scientific process, installation has obvious economic benefits easy to use.

- Q: Why are most of the chemical instruments made from glass?

- Of course, the glass is colorless and transparent is also very important, the front of some people said that the glass is cheap, I would like to deny, in fact, this glass is not often in general glass, high temperature, the cost is much higher than that

- Q: What material is used in the protective film in the middle of glass?

- At present, toughened glass membrane of glass raw materials generally have these brands. High end: Corelle & Schott. In the end: asahi. In the low-end: banxiaozi & luoyang.Just look different brands? The difference between JEANSWEST and Reaves? No, focusing on different materials.The same glass, medium and high-end glass called "aluminum silicon glass" in the low-end known as [sodium calcium glass]

1. Manufacturer Overview

| Location | Guangdong,China |

| Year Established | 2006 |

| Annual Output Value | |

| Main Markets | North America, Western Europe, South Asia |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | percent of export |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Double Shell Edge

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 Square Meter/Square Meters m²

- Supply Capability:

- 300,000 Square Meter/Square Meters per Year m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords