Double Cage Building Hoist Lifting Machine In China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

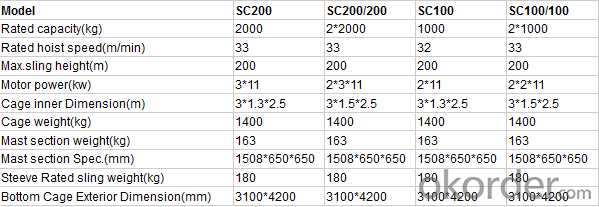

Specification

Introduction :

Construction lifter is mainly used to transport people or goods to multistoried building.Buwidely applies to such contruction sites as industrial and civil architecture,bridge,underground,large chimney,and ship industry,etc.

Construction lifter has such advantages as steady property, safety, reliability, flexible carrying, and good adaptability, etc., improves working efficiency, and can reduce working intensity.

Parameter :

FAQ of Building Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal construction equipment for vertical transportation in the field of construction.

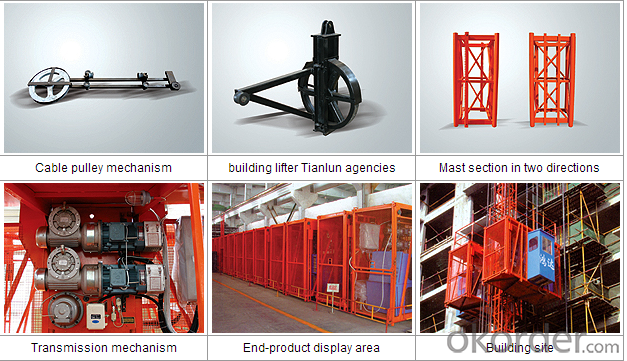

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide & protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance & exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.

Brief Introduction about CNBM

1, CNBM is the biggest state-owned company which has had been awarded Qualified construction machinery manufactures and most of the big project are using our products.

2, CNBM possess key technical research department and could design & produce special machinery for international clients.

3, We have had passed ISO9001:2008,CE and etc.

4. The successful long-time construction machinery operation in the world testifies that the CMAX products’ performance is stable.

5. More than 10 overseas branch office provide immediate commercial convenience and after service.

6. We also has building hoist, suspended platform, formwork, etc. We also signed the strategic partnership with Tadano (China), XCMG, Zoomlion, Sany and other prestigious crane manufacturer, getting the competitive cost price from them, and using our overseas marketing channel to promote their brands. We can provider a series of equipment for your building company customer and supply a basket scheme for the final users.

7. We have built a cover 50,000 square meter logistic park in, Dubai UAE, will be a great guarantee of our business in middle east and nearby area.

- Q: This question asks for a comparison between manual and automatic lifting systems used in construction equipment, highlighting their distinct features and operational differences.

- <p>Manual lifting systems in construction equipment rely on human effort to lift and move materials. They are often less expensive, require less maintenance, and are suitable for lighter loads or smaller-scale projects. However, they are labor-intensive, can be slower, and pose higher risks of injury due to the physical demands. Automatic lifting systems, on the other hand, use mechanical or electronic means to lift and move materials. They are more efficient, can handle heavier loads, and reduce the risk of injury by minimizing manual handling. These systems are often more expensive and require regular maintenance but offer precision, speed, and ease of operation, making them ideal for large-scale construction projects.</p>

- Q: This question asks for the method to determine the maximum weight an electric-hydraulic lifting system can handle.

- <p>To calculate the maximum load capacity of an electric-hydraulic lifting system, you need to consider several factors: the hydraulic cylinder's piston area, the pressure rating of the hydraulic system, and the mechanical strength of the system components. The formula to calculate the maximum load (P) is P = A * P, where A is the area of the piston in square inches or square meters, and P is the pressure in pounds per square inch (psi) or Pascals (Pa). Ensure to convert units if necessary. Additionally, account for safety factors and the mechanical limits of the system to determine the practical maximum load that the system can safely lift without risk of failure.</p>

- Q: Is it possible to repair or replace a hydraulic pump used in a building hoist system?

- <p>Yes, a hydraulic pump used in a building hoist can be repaired or replaced. If the pump is damaged or worn out, it can be serviced or repaired by professionals who specialize in hydraulic systems. If the damage is beyond repair, a new pump can be sourced and installed to ensure the hoist operates safely and efficiently. Regular maintenance and inspection are crucial to prevent major issues and to extend the life of the hydraulic pump.</p>

- Q: This question asks about the procedures and methods for maintaining and repairing a building hoist, which is a type of lifting equipment used in construction.

- <p>To maintain and repair a building hoist, follow these steps: Regularly inspect the hoist for any signs of wear and tear or malfunction. Lubricate moving parts as per the manufacturer's recommendations to reduce friction and prevent rust. Check and replace worn cables, pulleys, and other components. Ensure that safety devices like limit switches and emergency stops are functioning correctly. For repairs, address any mechanical failures, replace broken parts, and make sure the electrical system is in good condition. Always follow the manufacturer's guidelines and consult with a professional if the issue is complex or beyond your expertise. Regular maintenance and prompt repairs can extend the life of the hoist and ensure safe operation.</p>

- Q: This question asks for the safety precautions that should be taken when operating electric-hydraulic construction hoists.

- <p>Safety measures for using electric-hydraulic building hoists include regular maintenance and inspection to ensure all components are in good working order. Operators must be trained and certified, following all safety protocols. Never exceed the hoist's load capacity. Ensure that safety hooks and chains are in place and secure. Keep the hoist area clear of debris and unauthorized personnel. Use proper lifting techniques and avoid sudden starts or stops. Always inspect the load before lifting to ensure it is stable and secure. Emergency stop switches should be easily accessible. Ensure that all safety guards are in place and functioning properly. Adhere to all local regulations and manufacturer's guidelines.</p>

- Q: This question asks if a building hoist can be set up either inside or outside a building.

- <p>Yes, a building hoist can be installed both indoors and outdoors. The choice between indoor and outdoor installation depends on the specific requirements of the construction project, the available space, and the building's design. Outdoor hoists are often used for high-rise construction, while indoor hoists are more common in multi-story buildings or where external space is limited. Both types require careful planning and adherence to safety regulations to ensure the safe and efficient movement of materials and personnel.</p>

- Q: How much cable does the construction elevator 44KVA need?

- 44KW three phase power: 79A, BV5X16

- Q: This question asks for guidelines on the safe operation of a building hoist, a device used to lift materials in construction.

- <p>To use a building hoist safely, follow these guidelines: Ensure the hoist is properly installed and inspected by a qualified person. Never exceed the hoist's weight limit. Keep the hoist area clear of obstacles and ensure all safety devices are functioning. Do not use the hoist if there are any visible defects or damage. Always secure the load properly and ensure it is balanced. Never leave the hoist unattended while in operation. Use hand signals or a communication system to coordinate with the operator. Regularly inspect and maintain the hoist to prevent accidents. Always follow the manufacturer's instructions and adhere to local safety regulations.</p>

- Q: How to adjust the weight limit of the construction elevator

- It's very simple, there's a couple of buttons down here, okay

- Q: This question asks about the time required to install a building hoist, a device used for lifting materials in construction.

- <p>The time it takes to install a building hoist can vary significantly based on factors such as the type and size of the hoist, the specific building requirements, and the experience of the installation team. On average, it can take anywhere from a few hours to a couple of days. For smaller hoists, installation might be completed within a day, while larger, more complex systems could take longer. It's important to note that safety checks and regulatory compliance verifications are also part of the process, which can add to the total installation time.</p>

Send your message to us

Double Cage Building Hoist Lifting Machine In China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords