Buidling Hoist Large Lifting Capacity in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Building Hoist Description

Condition: New

Application: Construction

Payload(kg):3200

Lifting Speed(m/min):0~60

Motor Power(kw): 3*22

Safety Device: SAJ50-1.4

Cage: Single

Counterweight: No

Certification: CE,ISO

Place of Origin: China(Mainland)

Model Number: Type:SC320

Packaging & Delivery of Building Hoist

Packaging Detail: Nude package

Delivery Detail: 25-30days

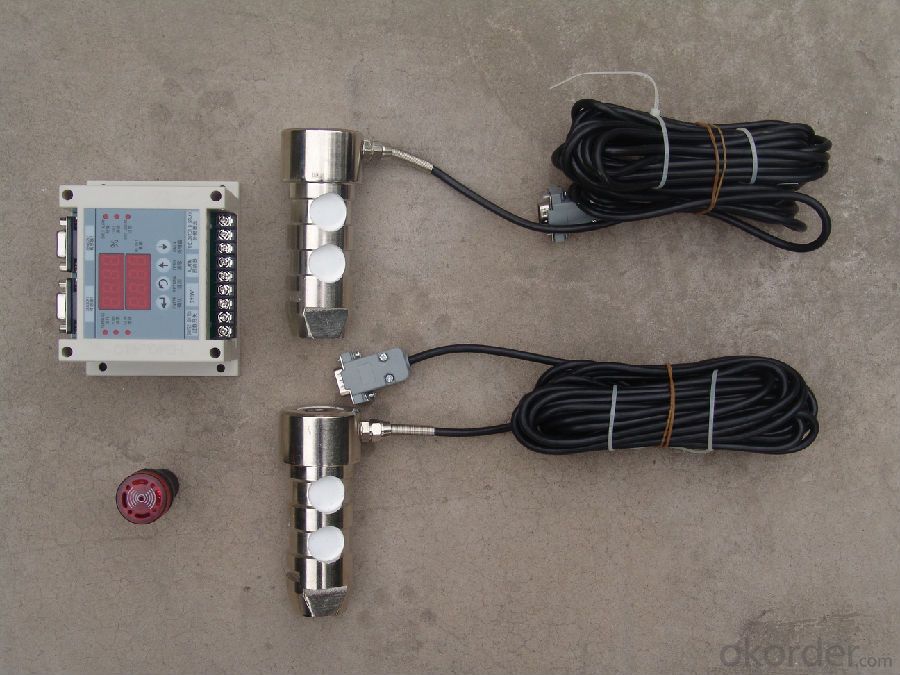

Building Hoist Images

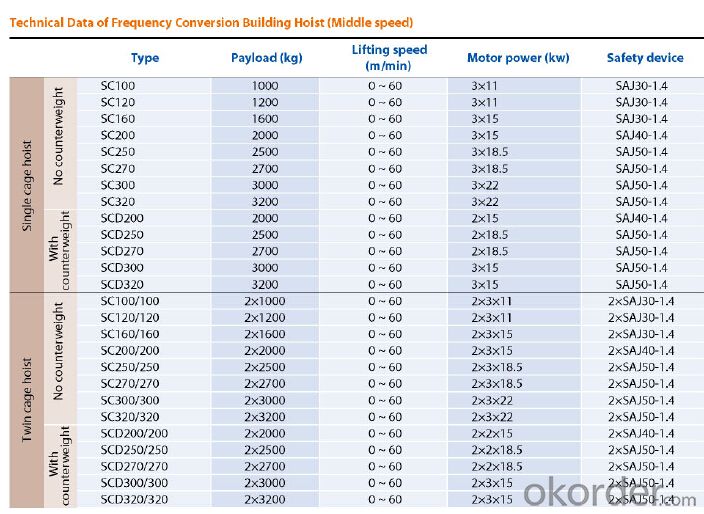

Building Hoist Specifiction

FAQ of Building Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide &

protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity

is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

- Q: This question asks about the measures to ensure that safety belts on a building hoist are correctly installed and utilized.

- <p>To ensure that safety belts on a building hoist are properly installed and used, follow these steps: 1. Regularly inspect the belts for any signs of wear, damage, or corrosion. 2. Ensure that the belts are securely fastened and properly adjusted according to the manufacturer's guidelines. 3. Conduct a thorough pre-use inspection before each operation to confirm that the belts are in good condition and functioning correctly. 4. Train all personnel on the proper use of safety belts and the importance of wearing them at all times while operating the hoist. 5. Implement a maintenance schedule to regularly check, clean, and lubricate the belts to prolong their lifespan and ensure optimal performance. 6. Replace any damaged belts immediately to prevent accidents and ensure the safety of workers.</p>

- Q: Is it possible to use a building hoist to lift various materials simultaneously?

- <p>Yes, a building hoist can be used for lifting multiple materials at once, provided the total weight does not exceed the hoist's load capacity. It's crucial to ensure that the materials are securely fastened and balanced to prevent tipping or damage. Always follow the manufacturer's guidelines and safety regulations to avoid accidents and ensure the safe operation of the hoist.</p>

- Q: This question asks for the process of changing the height at which a building hoist operates.

- <p>Adjusting the height of a building hoist typically involves a few key steps. First, ensure the hoist is powered off and disconnected from any power source to ensure safety. Next, locate the hoist's height adjustment mechanism, which may be a set of bolts or a telescoping column. Loosen any locking nuts or bolts that secure the current height setting. Adjust the hoist to the desired height by raising or lowering the platform or mast. Once the desired height is reached, tighten the locking nuts or bolts to secure the hoist in place. It's crucial to check the manufacturer's guidelines for your specific hoist model, as the process may vary. Always follow safety protocols and consult with a professional if you're unsure about any steps.</p>

- Q: What are the necessary maintenance tasks and considerations for ensuring the safe and efficient operation of a building hoist?

- <p>The maintenance requirements for a building hoist include regular inspections, lubrication, and checks on all mechanical components. It is crucial to inspect the hoist's cables, pulleys, and brackets for wear and tear. The drive mechanism and safety devices should be tested for proper functioning. Lubrication of moving parts is essential to reduce friction and prevent overheating. Additionally, the electrical system should be checked for any faults or damage. It's important to keep the hoist clean and free of debris to prevent any operational issues. Following the manufacturer's guidelines for maintenance intervals and procedures is vital to ensure the hoist remains safe and efficient.</p>

- Q: This question asks whether a building hoist can be utilized in both indoor and outdoor environments.

- <p>A building hoist can indeed be used both indoors and outdoors, depending on the specific model and design. Outdoor hoists are typically built to withstand weather conditions and are more robust, while indoor hoists are designed for controlled environments. It's crucial to ensure that the hoist is suitable for the intended environment to maintain safety and functionality. Always follow the manufacturer's guidelines and safety regulations when using a building hoist in any setting.</p>

- Q: Where is the location of the elevator in the project

- The position of construction elevator is usually set in the project to facilitate access to material, material handling and personnel up and down, not affecting the construction process.

- Q: This question asks for methods to prevent leakage in hydraulic cylinders used in building hoists.

- <p>To prevent hydraulic cylinder leaks in a building hoist, follow these steps: Regularly inspect and maintain the hydraulic system to ensure all seals and gaskets are in good condition. Replace any worn or damaged components promptly. Ensure the hydraulic oil is clean and at the correct level to avoid air bubbles or cavitation which can cause leaks. Check the cylinder rods for scratches or damage and polish or replace them if necessary. Maintain the correct operating pressure and avoid overloading the hoist. Regularly lubricate moving parts to reduce friction and wear. Implement a routine maintenance schedule to catch and address potential issues before they lead to leaks.</p>

- Q: This question asks about frequent issues related to building hoists and seeks solutions for these problems.

- <p>Common problems with building hoists include mechanical failures, electrical issues, overloading, and safety malfunctions. Mechanical failures can be fixed by regular maintenance, lubrication, and replacement of worn parts. Electrical problems may require checking wiring, connections, and replacing faulty components. Overloading can be prevented by strictly adhering to the hoist's weight limit and using load indicators. Safety malfunctions, such as brake failure, require immediate attention and may involve replacing brake pads or overhauling the braking system. Always ensure that hoists are used according to the manufacturer's guidelines and are regularly inspected by qualified personnel to prevent accidents and ensure safe operation.</p>

- Q: This question asks if building hoists can be utilized for extended periods of time in construction projects.

- <p>Building hoists are generally designed for temporary use in construction projects, facilitating the movement of materials and personnel. They are not intended for long-term operations. Their design and safety features cater to the specific needs of construction phases, which are temporary by nature. For permanent installations or long-term material handling, other types of elevators or lifts are more suitable. It is crucial to adhere to the manufacturer's guidelines and local regulations regarding the use and duration of operation for building hoists to ensure safety and compliance.</p>

- Q: What are the necessary safety rules and regulations that must be followed when operating a building hoist?

- <p>Safety regulations for using a building hoist include ensuring that the hoist is regularly inspected and maintained by qualified personnel. Operators must be trained and certified. The hoist should be equipped with safety devices such as limit switches, overload protection, and emergency stop buttons. Loads should never exceed the hoist's capacity, and the hoist should not be used in adverse weather conditions. Proper communication procedures must be followed, and a safety zone should be established around the hoist to prevent unauthorized access. Workers must wear appropriate personal protective equipment, and all safety guards and barriers must be in place and functioning correctly. Compliance with local and national regulations is also mandatory.</p>

Send your message to us

Buidling Hoist Large Lifting Capacity in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords