Construction Hoist New Double Cage Factory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Construction Hoist Description

The general building hoist manufactured by our company have the features as good quality, long life, wide application range and convenient for maintenance. The gearing adopted bearing,enameled cable, and oil seal. The racks and pinion adopts specal material and heat-treatment technique, which prolong the life of these parts. The steel structure uses quality steel from famous domestic manufacturers. The surface of the structure can apply paint-spray, parkerizing baking finish or hot galvanizing processing according to users requirments. The cage can be produced and decorated by aluminum molded board, punched-plate or figured aluminum board.

Main Features of Construction Hoist

1. The recomended cage dimension(L*W*H)(m): 2.0*1.0*2.5, 2.5*1.0*2.5, 2.5*1.3*2.5, 3.0*1.5*2,5, 3.2*1.5*2.5, 3.8*1.5*2.5, 4.0*1.5*2.5, 4.2*1.5*2.5 etc. We can also manufacture cages of other size according to the user.

2. The cage and the door material can be aluminum molded board, punched-plate, figured aluminum board or other type according to yout requirements.

3. The mast section and the tie-in surface can adopt paint-spray, or hot galvanizing processing..

Construction Hoist Specifiction

SC series product also has special design, such as reinforced guide rail with cross-section of 800mm, inclined type, special for cooling tower, etc. All the double cage building hoist can be changed into single cage type,

| Type | Payload(kg) | Lifting Speed (m/min) | Motor Power(kw) | Safety Device | ||

| Twin Cage Hoist | No Counterweight | SC100/100 | 2*1000 | 33 | 2*2*11 | 2*SAJ30-1.2 |

| SC120/120 | 2*1200 | 33 | 2*2*11 | 2*SAJ30-1.2 | ||

| SC160/160 | 2*1600 | 33 | 2*2*11 | 2*SAJ30-1.2 | ||

| SC200/200 | 2*2000 | 33 | 2*3*11 | 2*SAJ40-1.2 | ||

| SC250/250 | 2*2500 | 33 | 2*3*11 | 2*SAJ50-1.2 | ||

| SC270/270 | 2*2700 | 33 | 2*3*15 | 2*SAJ50-1.2 | ||

| SC300/300 | 2*3000 | 33 | 2*3*15 | 2*SAJ50-1.2 | ||

| SC320/320 | 2*3200 | 33 | 2*3*15 | 2*SAJ50-1.2 | ||

| With Counterweight | SCD200/200 | 2*2000 | 33 | 2*2*11 | 2*SAJ40-1.2 | |

| SCD250/250 | 2*2500 | 33 | 2*2*11 | 2*SAJ50-1.2 | ||

| SCD270/270 | 2*2700 | 33 | 2*2*15 | 2*SAJ50-1.2 | ||

| SCD300/300 | 2*3000 | 33 | 2*2*15 | 2*SAJ50-1.2 | ||

| SCD320/320 | 2*3200 | 33 | 2*2*15 | 2*SAJ50-1.2 |

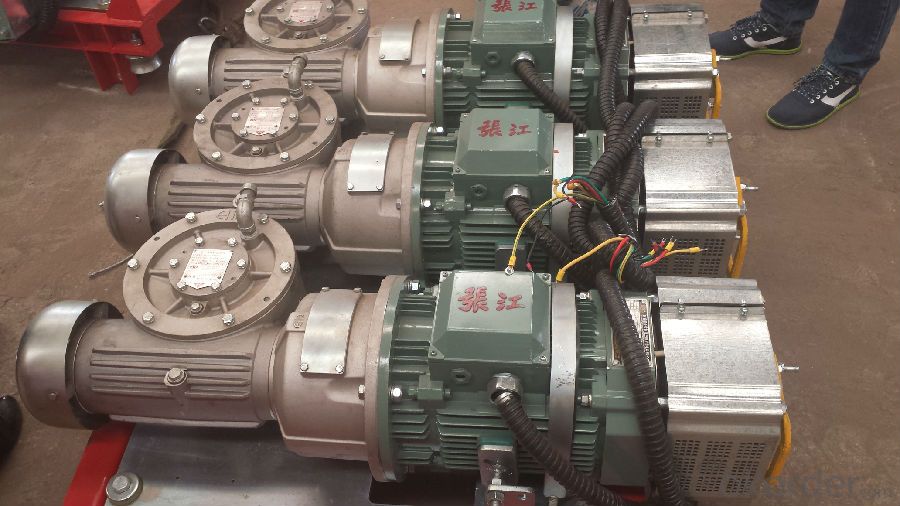

Images of Construction Hoist

FAQ of Construction Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide & protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance& exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.

- Q: What precautions should be taken when using lifting equipment to ensure safety?

- <p>Safety measures for lifting equipment include regular inspections and maintenance to ensure equipment is in good working order. Operators must be trained and certified for the specific equipment they are using. Safe lifting practices should be followed, such as never exceeding load limits, using the correct lifting points, and securing loads properly. Personal protective equipment (PPE) should be worn, and clear communication among the lifting team is essential. Additionally, a safe working environment should be maintained, free from obstructions and hazards, and emergency procedures should be in place and known by all involved.</p>

- Q: This question asks about the measures to ensure that safety belts on a building hoist are correctly installed and utilized.

- <p>To ensure that safety belts on a building hoist are properly installed and used, follow these steps: 1. Regularly inspect the belts for any signs of wear, damage, or corrosion. 2. Ensure that the belts are securely fastened and properly adjusted according to the manufacturer's guidelines. 3. Conduct a thorough pre-use inspection before each operation to confirm that the belts are in good condition and functioning correctly. 4. Train all personnel on the proper use of safety belts and the importance of wearing them at all times while operating the hoist. 5. Implement a maintenance schedule to regularly check, clean, and lubricate the belts to prolong their lifespan and ensure optimal performance. 6. Replace any damaged belts immediately to prevent accidents and ensure the safety of workers.</p>

- Q: This question asks about the measures taken to guarantee the safety and reliability of lifting equipment prior to its use in construction.

- <p>To ensure that lifting equipment is safe and reliable before using it in construction work, several key steps must be taken. Firstly, regular inspections and maintenance are crucial to identify any potential issues or wear and tear. Secondly, all equipment should be thoroughly tested and certified by qualified personnel to meet safety standards. Thirdly, proper training for operators is essential to ensure they understand how to use the equipment safely. Additionally, having a comprehensive safety plan in place, including emergency procedures, can help prevent accidents. Lastly, using equipment from reputable manufacturers and ensuring all components are in good working order are also vital for maintaining safety and reliability.</p>

- Q: There are two 18-story buildings under construction and tower cranes.

- In this case, you do not need to install the construction elevator at the main stage. After the main body is finished, install the tower crane, reinstall, mainly for decorate the vertical transport of the stage.

- Q: Is it possible for a building hoist to simultaneously lift and lower various materials?

- <p>Yes, a building hoist can be used to raise and lower different materials at the same time, provided it has the necessary capacity and the materials are properly secured. This is often done by using multiple hooks or platforms, each designated for different materials. It's crucial to ensure that the combined weight does not exceed the hoist's load limit and that safety protocols are strictly followed to prevent accidents.</p>

- Q: This question asks for the method to determine the maximum weight an object can safely be lifted by a lifting device.

- <p>To calculate the weight of an object that can be safely lifted by a lifting device, you must consider several factors. First, determine the lifting capacity of the device, which is the maximum weight it is designed to handle. This information is typically provided by the manufacturer. Next, account for the weight of any additional equipment, such as slings or cables, that will be used in the lift. Subtract this from the lifting capacity to find the maximum weight the object can be. Ensure all safety margins and regulations are observed, as these can affect the safe weight limit. Always err on the side of caution to prevent overloading the lifting device.</p>

- Q: This question asks for the steps or process involved in installing a building hoist, which is a type of crane used in construction to lift materials.

- <p>Installing a building hoist involves several steps: 1) Site preparation, ensuring the ground is level and strong enough to support the hoist. 2) Assembling the hoist tower, starting from the base and working upwards. 3) Installing the motor and drive system. 4) Attaching the cable and counterweight. 5) Rigging the hoist with safety devices and load limiters. 6) Conducting a thorough inspection and testing the hoist for safety and functionality. 7) Obtaining any necessary permits and approvals. It's crucial to follow the manufacturer's instructions and local regulations, and often requires a professional team for safe and proper installation.</p>

- Q: This question asks for the safety precautions that should be taken when operating electric-hydraulic construction hoists.

- <p>Safety measures for using electric-hydraulic building hoists include regular maintenance and inspection to ensure all components are in good working order. Operators must be trained and certified, following all safety protocols. Never exceed the hoist's load capacity. Ensure that safety hooks and chains are in place and secure. Keep the hoist area clear of debris and unauthorized personnel. Use proper lifting techniques and avoid sudden starts or stops. Always inspect the load before lifting to ensure it is stable and secure. Emergency stop switches should be easily accessible. Ensure that all safety guards are in place and functioning properly. Adhere to all local regulations and manufacturer's guidelines.</p>

- Q: This question asks for an explanation of the functioning of hydraulic cylinders in lifting equipment.

- <p>Hydraulic cylinders in lifting equipment operate by converting hydraulic pressure into linear mechanical motion. They consist of a cylinder barrel, a piston, and a piston rod. When pressurized fluid is introduced into the cylinder, it pushes the piston, which in turn moves the piston rod. This movement is what lifts or moves the load. The force exerted by the piston is proportional to the pressure of the fluid and the area of the piston. The cylinder's design allows for controlled and precise lifting, making it ideal for heavy-duty applications where power and control are required.</p>

- Q: What are the steps and considerations for maintaining a building hoist to ensure its safety and functionality?

- <p>To maintain a building hoist properly, follow these steps: Regularly inspect the hoist for any visible damage or wear. Lubricate moving parts as per manufacturer's recommendations. Ensure all safety devices are functioning correctly, including limit switches and emergency stop buttons. Check the hoist's electrical system for any signs of damage or wear. Keep the hoist clean and free from debris. Conduct a thorough inspection after any incident or near miss. Regularly test the hoist's load capacity to ensure it is within safe limits. Train operators on safe hoist operation and maintenance procedures. Always follow the manufacturer's guidelines and local regulations for maintenance and inspection.</p>

Send your message to us

Construction Hoist New Double Cage Factory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords