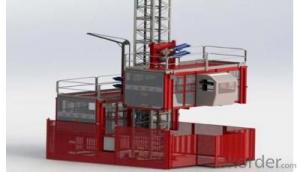

Construction Lifting Hoist 2 Ton Capacity Double Cage for Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Construction Lifting Hoist 2 Ton Capacity Double Cage for Sale

We are special supplier of building hoist in China, our building hoist have been Widely exported to all over the world and won good reputation, whose payload capacity is as much as 10000kg, lifting speed can reach up to 96m/min, and the erection height reaches up to 550m., our products have been widely used for transportation for both men and cargo in field of general buildings, but also industry, electric power, mining well, oil, chemical industry etc.

SC270TD, SC270/270TD building hoist:

1). Each cage load capacity: 2700kg

2). Lifting speed: 36m/min, or 0∼ 63m/min, or 0∼ 96m/min

3). Mast section: Paint or hot dipping zinc

4). Cage: Single cage or twin cage

5). Recommended cage inner dimension(LxWxH)(m): 2.5x1.3 x2.5; 3.0x1.3x2.5; 3.2x1.5x2.5; 3.6x1.5x2.5; 3.8x1.5x2.5; 4.0x1.5x2.5; 4.2x1.5x2.5, cage dimension is according to requirement of customer and special project.

6). Motor and reducing device: Made in China, can be SEW Germany according to requirements.

7). Counterweight: With counterweight or without counterweight

8). The colors of cage: Yellow, or red, or blue

9). Other each cage load capacity for your to choose: 1000kg, 2000kg, 2700kg, or 3200kg

| Type | Payload kg | Lifting speed m/min | Motor power kW | Inverter power kW | Counter Weight kg | ||

| Low speed | Single cage no counterweight | SC200GD | 2000 | 0~46 | 3×15 | 45 | 0 |

| SC270GD | 2700 | 0~46 | 3×18.5 | 55 | 0 | ||

| SC320GD | 3200 | 0~46 | 3×22 | 75 | 0 | ||

| Twin cage no counterweight | SC200/200GD | 2×2000 | 0~46 | 2×3×15 | 2×45 | 0 | |

| SC270/270GD | 2×2700 | 0~46 | 2×3×18.5 | 2×55 | 0 | ||

| SC320/320GD | 2×3200 | 0~46 | 2×3×22 | 2×75 | 0 | ||

| Middle speed | Single cage no counterweight | SC120GZ | 1200 | 0~63 | 3×15 | 45 | 0 |

| SC200GZ | 2000 | 0~63 | 3×18.5 | 55 | 0 | ||

| Single cage with counterweight | SCD200GZ | 2000 | 0~63 | 2×15 | 30 | 2000 | |

| SCD270GZ | 2700 | 0~63 | 2×18.5 | 37 | 2000 | ||

| SCD320GZ | 3200 | 0~63 | 3×15 | 45 | 2000 | ||

| Twin cage no counterweight | SC120/120GZ | 2×1200 | 0~63 | 2×3×15 | 2×45 | 0 | |

| SC200/200GZ | 2×2000 | 0~63 | 2×3×18.5 | 2×55 | 0 | ||

| Twin cage with counterweight | SCD200/200GZ | 2×2000 | 0~63 | 2×15 | 2×30 | 2×2000 | |

| SCD270/270GZ | 2×2700 | 0~63 | 2×18.5 | 2×37 | 2×2000 | ||

| SCD320/320GZ | 2×3200 | 0~63 | 2×3×15 | 2×45 | 2×2000 | ||

| High speed | Single cage no counterweight | SC100GS | 1000 | 0~96 | 3×22 | 75 | 0 |

| SC120GS | 1200 | 0~96 | 3×22 | 75 | 0 | ||

| SC200G | 2000 | 0~96 | 3×22 | 90 | 0 | ||

| SC200GS | 2000 | 0~96 | 3×22 | 90 | 0 | ||

| Single cage with counterweight | SCD200G | 2000 | 0~96 | 3×15 | 45 | 2000 | |

| SCD200GS | 2000 | 0~96 | 2×22 | 45 | 2000 | ||

| SCD270G | 2700 | 0~96 | 3×18.5 | 55 | 2000 | ||

| SCD320GS | 3200 | 0~96 | 3×22 | 75 | 2000 | ||

| Twin cage no counterweight | SC100/100GS | 2×1000 | 0~96 | 2×3×22 | 2×75 | 0 | |

| SC120/120GS/ | 2×1200 | 0~96 | 2×3×22 | 2×75 | 0 | ||

| SC200/200G | 2×2000 | 0~96 | 2×3×22 | 2×90 | 0 | ||

| SC200/200GS | 2×2000 | 0~96 | 2×3×22 | 2×90 | 0 | ||

| Twin cage with counterweight | SCD200/200G | 2×2000 | 0~96 | 2×3×15 | 2×45 | 2×2000 | |

| SCD200/200GS | 2×2000 | 0~96 | 2×2×22 | 2×45 | 2×2000 | ||

| SCD270/270G | 2×2700 | 0~96 | 2×3×18.5 | 2×55 | 2×2000 | ||

| SCD320/320G | 2×3200 | 0~96 | 2×3×22 | 2×75 | 2×2000 | ||

| SCD320/320GS | 2×3200 | 0~96 | 2×3×22 | 2×75 | 2×2000 | ||

- Q: This question asks for the steps or procedures to keep a building hoist in good working condition.

- <p>Maintaining a building hoist involves regular inspections, lubrication, and repairs. Ensure all safety features are operational and that the hoist is clean and free of debris. Check cables for wear and replace them if necessary. Lubricate moving parts as per the manufacturer's recommendations. Inspect the electrical system for any signs of damage or wear. Regularly test the hoist's load capacity and emergency stop functions. Keep a maintenance log to track all inspections and repairs. If any issues are identified, address them promptly to prevent accidents and ensure the hoist operates safely and efficiently.</p>

- Q: This question asks about the typical issues encountered with building hoists and the methods to address these problems.

- <p>Common faults in building hoists include mechanical failures such as worn gears or chains, electrical issues like short circuits or malfunctioning controls, and structural problems such as misaligned guides or damaged safety devices. To deal with these issues, regular maintenance and inspection are crucial. Mechanical faults can often be resolved by replacing worn parts or lubricating moving components. Electrical problems may require a thorough check of wiring and control systems, possibly involving a qualified electrician. Structural issues might necessitate adjustments or repairs to ensure the hoist operates safely. In all cases, following the manufacturer's guidelines and safety protocols is essential to prevent accidents and ensure the hoist's reliable operation.</p>

- Q: 6 layer of brick and concrete construction project, have tower crane still need construction elevator?

- 6 floors of brick and concrete construction projects, tower cranes do not need construction elevator. Brick structure refers to the building of the wall of vertical bearing structure, column, etc. By using brick or block masonry, lateral load-bearing beam, reinforced concrete structure is adopted for floor, roof boarding, etc. In other words, the masonry structure is a small amount of reinforced concrete and most brick wall bearing structures. The masonry structure is a kind of hybrid structure, which is composed of brick wall and reinforced concrete beams. Suitable for small width and depth, room area is small, multilayer or low-rise buildings, for load bearing walls can't change, while the frame structure of wall body can be altered.

- Q: Is it possible to use a building hoist for the transportation of goods or materials?

- <p>Yes, building hoists are commonly used to transport goods and materials in construction projects. They are designed to lift and lower heavy materials such as bricks, cement, and tools, making the construction process more efficient and reducing the need for manual labor. Building hoists are equipped with safety features to ensure the secure transportation of materials, and they are an essential tool in many construction sites.</p>

- Q: Elevator installation approach, need to give the total package (inspect) what data, come a master to answer the detail point

- In ten days: installation company qualification (including business license, qualification certificate, safety production license, organization code certificate and company performance, etc.), installation personnel qualifications (including the principal, special operations personnel, etc.), installation construction scheme (including the construction organization design, safety and civilized construction scheme, construction progress) The installation process: in materials to submit for approval (material inspection report, certificate, etc.), play equipment to submit for approval (mechanical factory qualified certificate, safe use license, etc.) After the construction is completed, the certificate of safety inspection (which needs to be provided by the special security agency)

- Q: This question asks about the measures taken to ensure that lifting equipment remains safe and functional in various weather conditions.

- <p>To ensure that lifting equipment is safe and reliable in all weather conditions, regular maintenance and inspection are crucial. Equipment should be designed with weather-resistant materials and should be tested periodically to withstand extreme temperatures, humidity, and precipitation. Protective covers or enclosures can be used to shield equipment from the elements. Additionally, training operators on the safe use of equipment in different weather conditions is essential. Emergency procedures should be in place for extreme weather events, and equipment should be regularly checked for wear and tear that could be exacerbated by weather conditions.</p>

- Q: This question asks for the steps or methods to keep a building hoist in good condition and fix any damages.

- <p>To maintain and repair a damaged building hoist, follow these steps: Regularly inspect the hoist for wear and tear, checking cables, pulleys, and brackets. Lubricate moving parts to reduce friction and prevent rust. Replace damaged or worn-out components promptly. Ensure all safety features are functioning correctly. If a hoist is severely damaged, consult with a professional to assess the damage and perform necessary repairs. Always adhere to the manufacturer's guidelines and safety regulations during maintenance and repair processes.</p>

- Q: Is it permissible to use personal manual equipment for lifting objects instead of a construction hoist?

- <p>While it might be tempting to use your own manual equipment for lifting objects, it's generally not recommended for construction purposes. Building hoists are specifically designed for heavy lifting and are equipped with safety features that manual equipment may lack. Using manual equipment can pose significant safety risks, including the potential for accidents and injuries. Always follow safety regulations and use the appropriate equipment for the task at hand to ensure the safety of everyone on site.</p>

- Q: Is it permissible to use a building hoist for lifting people or animals?

- <p>No, building hoists are not designed for lifting people or animals. They are specifically engineered for the transportation of materials and construction equipment. Using a building hoist for this purpose is dangerous and can lead to accidents. It is essential to adhere to safety regulations and use appropriate equipment for lifting people or animals to ensure their safety and comply with legal standards.</p>

- Q: This question asks for the distinctions between two types of building hoists: manual and automatic.

- <p>Manual building hoists require human effort to operate, typically involving a pulley system and manual controls. They are generally less expensive but slower and more labor-intensive. Automatic building hoists, on the other hand, are motorized and can be programmed to lift and lower loads with minimal human intervention. They offer greater efficiency, speed, and safety, but come at a higher cost. Automatic hoists are also more suitable for high-rise construction due to their ability to handle heavier loads and operate over greater distances.</p>

Send your message to us

Construction Lifting Hoist 2 Ton Capacity Double Cage for Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords