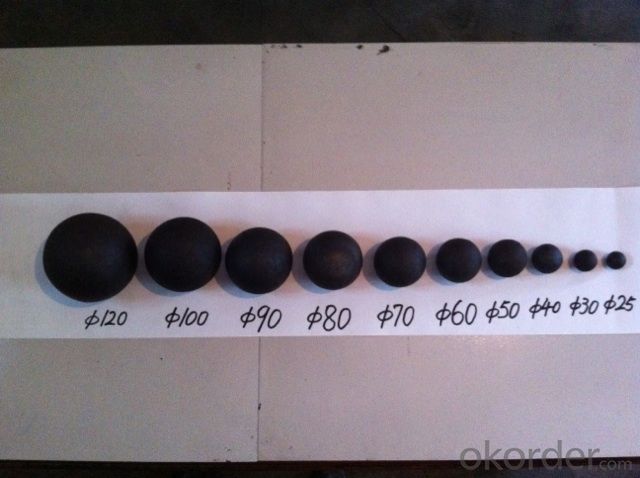

Dia.20-150MM HRC53-65 Hot Rolling Forged Grinding Media Ball Made in China Used for Mineral Processing

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MTS m.t.

- Supply Capability:

- 200000MTS/Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Dia.20-150MM HRC53-65 Hot Rolling Forged Grinding Media Ball Made in China Used

for Mineral Processing:

1.Grinding Ball Dia.20-150mm

2.Wear-resistant,High impact value

3.High combined efficiency

4.Hardness 55-65HRC

5.Low breakage

Features of Dia.20-150MM HRC53-65 Hot Rolling Forged Grinding Media Ball Made in China Used for

Mineral Processing:

1) In general, forged steel ball has high hardness: surface hardness to 55-68 HRC, volume hardness of 50-63 HRC

2) impact toughness high: impact toughness more than 12 J / cm2.

3) broken rate is low: the actual broken rate is not higher than 1%.

4) loss of grinding forged steel ball round rate is low.

Chemical Composition of Dia.20-150MM HRC53-65 Hot Rolling Forged Grinding Media Ball Made in

China Used for Mineral Processing:

Brand | Material | C | Mn | Si | Cr | S | P | V |

TITLE -1 | 50MN | 0.48-0.56 | 0.70-1.0 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 | |

TITLE -2 | 60MN | 0.57-0.65 | 0.70-1.0 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 | |

TITLE -3 | 65MN | 0.60-0.70 | 0.90-1.20 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 | |

TITLE -4 | 75Mn | 0.72-0.92 | 0.17-0.37 | 0.17-0.37 | 0.4-0.6 | ≤0.035 | ≤0.035 | |

TITLE -5 | 75MnCr | 0.70-0.85 | 0.7-0.8 | 0.17-0.37 | 0.2-0.7 | ≤0.03 | ≤0.03 | |

TITLE -6 | 75SiMn | 0.70-0.90 | 0.7-1.2 | 0.4-0.8 | ≤0.25 | ≤0.03 | ≤0.03 | |

TITLE -7 | Wear-resistant Alloy | 0.5-0.65 | 0.4-1.0 | 1.4-1.8 | 0.9-1.2 | ≤0.03 | ≤0.03 | 0.1-0.2 |

Chemical Composition of Dia.20-150MM HRC53-65 Casting Steel Grinding Media Ball Made in China Used

for Mineral Processing:

Name | Material | C | Si | Cr | Mn | S | P |

TITLE -8 | Cr-22-32% | 2.0-2.8 | ≤1.0 | 22-32 | 0.5-2.0 | ≤0.06 | ≤0.08 |

TITLE -9 | Cr-17-22% | 2.0-2.8 | ≤1.0 | 17-22 | 0.5-2.0 | ≤0.06 | ≤0.08 |

TITLE -10 | Cr-15-17% | 2.2-3.0 | ≤1.0 | 15-17 | 0.5-2.0 | ≤0.06 | ≤0.08 |

TITLE -11 | Cr-11-14% | 2.2-3.2 | ≤1.0 | 11-14 | 0.5-2.5 | ≤0.06 | ≤0.08 |

TITLE -12 | Cr-5-10% | 2.1-3.2 | ≤1.2 | 5-10 | 0.5-1.5 | ≤0.06 | ≤0.08 |

TITLE -13 | Cr-1.5-3% | 2.2-3.5 | ≤1.2 | 1.5-3 | 0.5-1.5 | ≤0.06 | ≤0.08 |

- Q: Why do cheap cars like stamping parts instead of casting parts?

- Separation process is also called blanking, the purpose is to make the stamping parts along a certain contour line from the sheet metal separation, at the same time guarantee the quality requirements of the separation section. Stamping is a highly efficient production methods, the use of compound die, especially the multi station progressive die stamping process can be completed in a multi machine, realized by belt uncoiling, leveling, punching, forming and finishing automatic production. High production efficiency, good working conditions, low production costs, can produce hundreds of parts per minute. The purpose of forming processes is to allow the sheet to undergo plastic deformation without breaking the billet and to make the desired shape and size. In actual production, a variety of processes are often applied to a workpiece. Blanking, bending, shearing, drawing, bulging, spinning, and straightening are the main types of stamping machines.

- Q: In theory, which is more expensive, forging parts or casting parts?

- It depends on the structure. In theory, the shape of the forging is relatively simple, but the requirement of internal structure is relatively high

- Q: the parts of the threaded hole is casting, casting the hole directly, and then tapping or casting, and then punch 10When the casting is ready, punch it again before tapping it Is the hole casting good or is it punched and tapped on the drilling machine after casting?

- Single for this problem, the direct casting out of course good. But many times because of the limitations of the process, so we choose the post-processing hole

- Q: What are the casting parts processing engineering?

- Among them, special casting has metal mould casting, pressure casting, low pressure casting, lost wax casting (also known as precision casting), shell casting, lost foam casting, centrifugal casting, continuous casting, V casting, and clay casting

- Q: What should I pay attention to when designing a casting structure?

- The basic structure of unit 3 in the design of metal casting casting and its parameters are selected, usually should also pay attention to: (1) because of the metal type heat quickly, so the metal type casting minimum wall thickness should be bigger than the sand casting casting casting; (2) the inner wall of the internal ribs and the thickness of a should be connected the outer wall thickness of 0.6 to 0.7, or as the inner wall (rib) cold slowly, cracks in the wall at the junction in the casting shrinkage; (3) to prevent generating white grey cast iron, in addition to taking measures in the process, must make the wall thickness is not too thin (some information that cast fillet at the corner of the wall thickness of 15mm or more, with metal casting casting must be in the corner, for Aluminum Alloy, metal casting magnesium alloy castings shall not be less than 3 ~ 4m; (4) because of the metal type and the core that, for To facilitate the extraction of castings and casting out type, slope casting should be suitably large than sand casting metal casting, the general should be 30% ~ 50%, it should be pointed out that in addition to the height of the slope of casting size and alloy type, wall, is also related to the casting surface position, where the cooling and contraction of the metal type the surface of casting surface can be designed from the tendency of small inclination, while casting shrinkage tend to be pressed on the surface of metal casting type should be given greater inclination.

- Q: Question, such as title, I hope I don't copy the definition of rolling and casting in Baidu encyclopedia, thank you

- uch as: automobile transmission shaft adopts mechanical rolling machine with good performance, gray cast iron can play seismic effect effectively, with good thermal conductivity of radiator graphite in gray cast iron, the aircraft engine turbine blade by casting directional solidification casting and Dan Jingzhu.Do everything we can to make the best use of it, the advantages and disadvantages of rolling and casting, and you'll find it yourself, Baidu, depending on how you use it

- Q: What kind of flaw detector is better for casting parts?

- Casting using the detector test, you must first determine the detection process, such as the detection of surface and near surface crack defects, such as casting, recommended by CYD-3000, or CYD-5000 mobile magnetic testing machine for testing.

- Q: Lathe processing stainless steel casting parts to use what type of tool, the speed into the amount of how much tool angle

- It has something to do with the size of your work, and it has a lot to do with the blade you're using right now.

- Q: Is 316 casting better than 304 casting?

- The degree of difficulty in the process of casting depends mainly on the structure, precision requirements, and hardness of the casting. It is comprehensive. There is no simple comparison of the material to determine the degree of difficulty in processing

- Q: How to solve casting defect casting?

- Prevention methodReduce the gas in the metal liquid and oxidize the slag, improve the fluidity of the metal liquidIncrease pouring temperature and pouring speed, strengthen slag collection, slag block or bottom pouring bag, teapot ladle pouring, can not cut off when pouring, prevent the slag from blocking the nozzle, and cause the casting to breakIncrease the sprue and sprue height, increase the runner section area and the sprue number, and improve the filling speed and the metal hydrostatic headImprove the casting design and increase the thickness of the thin-wall part of the castingChange the pouring position and pouring system, the casting thin wall plane is located at the top and away from the gate, to prevent the filling of liquid metal splashing, eddy current, avoid metal stream in the casting thin sections or core support, cold iron, insert the confluence, when necessary, take horizontal vertical pouring cold or inclined castingIncrease the permeability of core and sand, strengthen the exhaust of mould, and the quantity of air outlet and riser should be enoughChange the size and location of the core, the inner cold iron, the core support, the internal cold iron, the insert should be no rust, no oil pollutionCheck the type, tight box, press the operation of iron is safe, to prevent running fire

1. Manufacturer Overview

| Location | Shandong,China |

| Year Established | 2000 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | Domestic Market, South Asia, Southern Europe, Northern Europe, Central America |

| Company Certifications | ISO9001;IS014001 Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | |

| No.of Employees in Trade Department | 10-20 People |

| Language Spoken: | English;Chinese; |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Grinding Balls; Grinding Rods; Grinding Cylpebs. |

| Product Price Range | Average |

Send your message to us

Dia.20-150MM HRC53-65 Hot Rolling Forged Grinding Media Ball Made in China Used for Mineral Processing

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MTS m.t.

- Supply Capability:

- 200000MTS/Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords