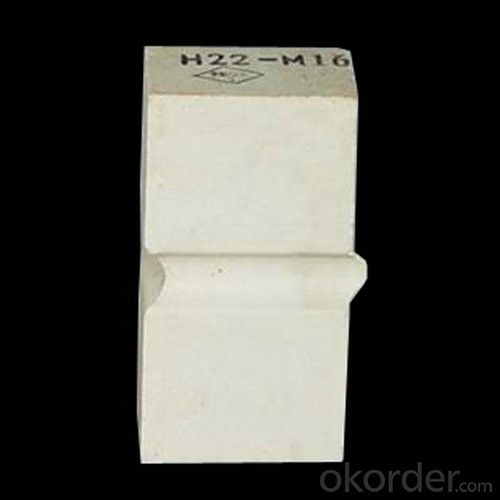

Corundum Mullite Brick for Hot Furnace - High Quality Corundum Brick

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Mullite refractry brick with features as following:

1.raw material: refractory brick of high quality bauxite clinker

2.main maneral:mullite

3.performance: this lind of refractory brick has good high temperature and chemical erosion resistance

4.certificate:ISO9001-2000

5.function:refractory used in each position of linings of blast furnace and other industry

6.physical and chemical performance:

Items | Mullite brick M72 | Mullite corundum brick M80 | Special mullite corundum brick SM80 |

Encoding | M72 | M80 | SM80 |

Al2o3 % | ≥72 | ≥78 | ≥80 |

Sio2 % | -- | -- | ≤19 |

Fe2o3 % | ≤0.8 | ≤1.0 | ≤0.5 |

Bulk density g/cm3 | ≥2.55 | ≥2.65 | ≥2.9 |

Apparent porosity % | ≤17 | ≤18 | ≤19 |

Cold crushing strength mpa | ≥80 | ≥80 | 5 |

Thermal shock resistance | Excellent | Excellent | Very good |

Softening under load | --- | ≤1700 | 1700 |

Thermalexpansion % | -- | 0.6 | 0.6

|

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control are conducted by workers and then each piece will be sorted and examined by quality supervis

Q5: Can you give me a brief introduction of the application of your products?

A5: CNBM (China National Building Material) core refractory business comprises the production, sale and installation of high-grade refractory products, the development and implementation of customized system solutions as well as rendering outstanding services for the key industries in Glass, Iron& Steel, Petrochemical, Cement, Ceramic and Nonferrous Metals.

- Q: How much is a thermal brick?

- If you really want to buy thermal insulation brick, do not simply look at the price, but also to consider the quality of the product. (a piece of brick in the market basically in 6 yuan, if there is a floating price if it is because of the size of the insulation brick or distance, but floating slightly.)

- Q: Zirconium corundum 25 content and 40 content, how to distinguish in appearance?

- It is in the production process, zirconium corundum bricks are likely to cause pollution.Fused zirconia corundum brick is also called AZS AZS English is abbreviated to AZS, is based on three chemical composition of Al2O3 - Zr02 - Sio2 phase diagram of three component system, according to the content of the order, Al2O3 A, Zr02 Z, Sio2 S, national standards for the use of this abbreviation, such as No. 33 cast brick, abbreviated as AZS, 33#, No. 36 fused zirconium corundum brick, abbreviated as AZS, 36#, No. 41 fused zirconium corundum brick, abbreviated as AZS - 41#.

- Q: What is the main component of corundum?

- The name of corundum originates from India and is the name of mineralogy. There are three main variants of corundum Al2O3, which are alpha -Al2O3, beta -Al2O3 and gamma -Al2O3 respectively. Corundum is second only to diamond.

- Q: Which is good, glazed brick and whole cast glazed brick?

- These two tiles have their respective advantages and disadvantages, in fact, to say which kind of good, mainly depends on the decoration of personal preferences and the location of the shop. If it is only the shop wall, then design and pattern rich whole glazed tile is good, it can make the room impressive, improve decorative effect, make the decoration style to fit the characteristics of his personality. In addition, clean up is relatively easy, not easy to contaminated with oil stains and other pollutants. If you are laying tile, suggested the use of tiles, tiles of good antiskid effect, water absorption rate is relatively low, so the kitchen toilet bathroom and other wet places is not easy to water seepage, improve the convenience of life.

- Q: Wave tile and throwing glaze, tile which good?

- These two tiles have their respective advantages and disadvantages, in fact, to say which kind of good, mainly depends on the decoration of personal preferences and the location of the shop. If it is only the shop wall, then design and pattern rich whole glazed tile is good, it can make the room impressive, improve decorative effect, make the decoration style to fit the characteristics of his personality. In addition, clean up is relatively easy, not easy to contaminated with oil stains and other pollutants. If it is laying floor tiles, tile Douglas suggested the use of tiles, tiles of good antiskid effect, water absorption rate is relatively low, so the kitchen toilet bathroom and other wet places is not easy to water seepage, improve the convenience of life.

- Q: What refractory materials are adopted in each part of the blast furnace?

- The lower part of the shaft due to high temperature and dust by scouring and alkali metal vapor erosion, so the requirements for the slag resistance, alkali resistance and high temperature resistance, wear resistance of high quality clay brick, high alumina brick, carborundum brick or corundum brick. Belly temperature reaches 1400~1600, and slag, steam erosion, erosion and corrosion is strong, therefore, the silicon carbide reaction bonded silicon carbide brick.

- Q: What is the difference between corundum and high alumina?

- The main components of high alumina brick are high alumina bauxite, mullite and partial corundum sand.The difference between them lies in the content of alumina and the alumina refractory products with alumina content higher than 48%The content of Al2O3 is higher than 90%, which is called corundum brick.

- Q: High temperature refractory material?

- Acid refractory with silicon oxide (SiO2) as the main ingredient, commonly used are silica brick and clay brick is siliceous. Products containing more than 93% SiO2, the use of raw materials with silica, silica and other waste brick. Acid slag erosion ability is strong, but vulnerable to the erosion of basic slag, its softening temperature is very high that is close to the refractory, the volume does not shrink after repeated burning, or even a slight swelling, but the thermal shock stability. Silica is mainly used for thermal equipment of coke oven, glass furnace, furnace and other acidic silica brick, according to the physicochemical indexes and SiO2 content can be divided into several levels, mainly brick for glass furnaces and used for coke oven two kinds of brick clay brick. With refractory clay or bauxite clinker as main raw material, containing 30% to 46% of alumina, refractory degrees 1580 to 1770 DEG C, weak acid refractory material, heat shock resistance, resistance to acid slag, wide application Pan, clay brick with refractory clay as main raw material is called ordinary clay brick, made with bauxite clinker as main raw material, the porosity in the clay brick below 17% is called low porosity clay brick. Two kinds of clay brick and according to the physicochemical indexes which were divided into several grades, the price difference between ordinary clay brick and low porosity clay brick greatly.

- Q: How do corundum bricks bind?

- Each refractory brick is provided with corresponding refractory mud, and corundum bricks are bonded with corundum mud.

- Q: Ask for help about the phase of refractory material

- Secondary crystalline phase. The second phase and second phase or second phase, and the main crystal phase and is in high temperature liquid phase coexistence in refractory material, the number and influence on high temperature properties of materials is the main crystal phase is small second phases. As to the main crystalline phase of periclase magnesia chrome brick, magnesia brick, magnesia brick and magnesia calcium brick respectively containing Cr spinel, spinel, forsterite and calcium silicate two are secondary phase. There are structure of refractory refractory material in the crystal phase, especially the direct combination of high melting point and so on, the resistance to high temperature also tend to benefit. Compared with the ordinary brick, the second phase of the refractory products, make the products refractoriness under load are improved. Many according to mineral composition of refractory material named, such as mullite corundum brick, corundum mullite brick, is its main crystal phase and the second phase composite named. The former is mainly crystal phase, the latter is sub crystalline phase.

Send your message to us

Corundum Mullite Brick for Hot Furnace - High Quality Corundum Brick

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords