Corundum Brick - Refractory Insulating Brick CNBM Made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

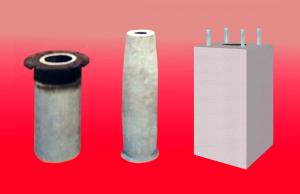

Refractory insulating brick

ISO 9000--2008

Refractory brick

insulating brick

Henan Province Refractory Materials member

Refractory insulating brick

High temperature performance

high volume density

high strength

good abrasion resistance and anti-acid erosion

JM - 23

TEMP 1260

BD 0.55

CSS 1.0

RLC 0.3

THERMAL CONDUCTIVITY 400 'C 0.15

1000 'C 0.24

AL2O3 47

SIO2 45

JM-28

TEMP 1500

BD 1.0

CSS 2.3

RLC 0.5

THERMAL CONDUCTIVITY 400 'C 0.33

1000 'C 0.42

AL2O3 64

FE2O3 0.7

JM - 30

TEMP 1650

BD 0.9-1

CCS 2.7

RLC 0.6

THERMAL CONDUCTIVITY 400 'C 0.41

1000 'C 0.48

AL2O3 74

SIO2 22

ISO 9000--2008

ISO 9000--2000

Zhengzhou Functional Unshaped Refractory Material Engineering Technology Research Center

Henan Province Refractory Materials Strategic Alliance Member

Award for Henan Province Science and Technology Advancement

- Q: What is the main component of corundum?

- The name of corundum originates from India and is the name of mineralogy. There are three main variants of corundum Al2O3, which are alpha -Al2O3, beta -Al2O3 and gamma -Al2O3 respectively. Corundum is second only to diamond.

- Q: What material is used in an iron smelting furnace?

- Often used insulation refractories are diatomite products, asbestos products, insulation panels and so on.

- Q: What is the price of concrete self insulation bricks?

- If you really want to buy thermal insulation brick, do not simply look at the price, but also to consider the quality of the product. (a piece of brick in the market basically in 6 yuan, if there is a floating price if it is because of the size of the insulation brick or distance, but floating slightly.)

- Q: What does refractory consist of?

- According to the chemical characteristics of refractory raw materials can be divided into acidic refractory materials, such as silica, zircon etc.; neutral refractory raw material, such as corundum, bauxite, mullite (acidic) (acidic), Ge (alkaline) iron and graphite; alkaline refractory materials, such as magnesite, dolomite, magnesium sand calcium sand.

- Q: What equipment is used for producing diamond blanks? How much is the investment?

- Plus all the cables fifty thousand. Steel 10000 yuan. Corundum bricks; insulating bricks; clay bricks, these three require more than ten thousand. The electrode is about one hundred thousand. It's just an investment in an electric furnace. Together with the rear section processing and raw materials need hundreds of thousands of.

- Q: Wave tile and throwing glaze, tile which good?

- Vitreous tile is all ceramic tile, the material is hard, strong wear resistance, smooth finish is very good, in general, looks very bright. Microcrystalline brick, corundum brick Market said, they really mean bohuazhuan. Because of its low water absorption and high strength and hardness, glazed tile has been widely used. Many hotels, shopping malls and office space are widely used glass tile.

- Q: Expansion ratio of lightweight corundum refractory bricks

- Now with the production of lightweight foam corundum brick, basically still meters with molding casting, moulding after together with die in the drying room drying in 60~70 C 4 days of release, then the appropriate drying, finally after 1300 and 1550 C firing, the total burning time: 50~60h. Light corundum brick after firing is usually not the size and shape of accurate, so that products after the kiln to mechanical or manual cutting, can be made into a density of 0.8 - 1.3g/cm3, 4MPa compressive strength and porosity, the thermal conductivity of 70%~80% 0.17W/ (M - K), light-weight corundum brick use temperature of 1500~1700 DEG C.

- Q: Can the PE sintering plate dust collector be suitable for dust removal in the coking plant?

- Do not know where the coking plant do dust treatment, processing conditions are different, the dust collector is not the same

- Q: Ask for help about the phase of refractory material

- Major crystalline phase. The main crystalline phase is a crystalline phase that constitutes the principal part of the material structure and has a high melting point and a dominant role in the properties of the material. The properties, quantities, distribution and bonding state of the main crystalline phases of refractory determine the properties of the products directly. A lot of refractory products, such as mullite brick, corundum brick, magnesia brick, magnesia spinel brick, silicon carbide refractory products, etc., are the main phase named.

- Q: Can the fire clay be reused?

- Refractory soil cannot be reused.Clay refractory soil 1, characteristics and uses: Clay refractory brick is a weak acid refractory material, its thermal stability is good, suitable for hot air furnace, all kinds of boiler lining, and flue, smoke room, etc.. 2, product specifications form: standard shape, general, special-shaped and special-shaped brick. Physical and chemical properties of fireclay bricks.

Send your message to us

Corundum Brick - Refractory Insulating Brick CNBM Made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords