Construction Hoist SC450 Series /Material Hoist /Building Hoist /Industrial Hoist /Lift /Elevator

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 20 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

CNBM designed and manufactured a brand new model construction hoist SC450 by absorbing advanced technology from all over the world, together with CNBM's unique and latest designing conception. The mast type of SC450 is 450x450mm and the rated load is 2000kg, it is a kind of light duty hoist. SC450 adopts modular design, frequency control and strong mechanic strength steel, with compact structure, comfortable riding, high efficiency, convenient transportation and evergy saving. It is the best choice for vertical transportation of people and materials below 2000kg on construction sites.

Features:

1. Modular design, easy to make different combinations according to the requirement.

2. Can produce cage with length from 2.0m to 3.2m.

3. Adopting strong mechanic strength steel which makes light structure and large load capacity.

4. With many different models of cage door available. Aluminum structure, light weight and easy to open.

5. Both single cage and double cage are applicable. Fast and easy conversion between left and right cage.

6. Compact structure, convenient for transportation - can be directly packed into container.

7. Using gear to drive and brake, it is efficient and evergy saving.

8. Main components are hot dip galvanized which guarantee longer operational life.

9. Cable basket or cable guiding device with aluminum rail according to the requirement.

10. With frequency control and direct start available.

11. Advanced load inspection device, ensuring driving safety.

12. Accredited with European standard EN12159 and China standard GB/T10054.

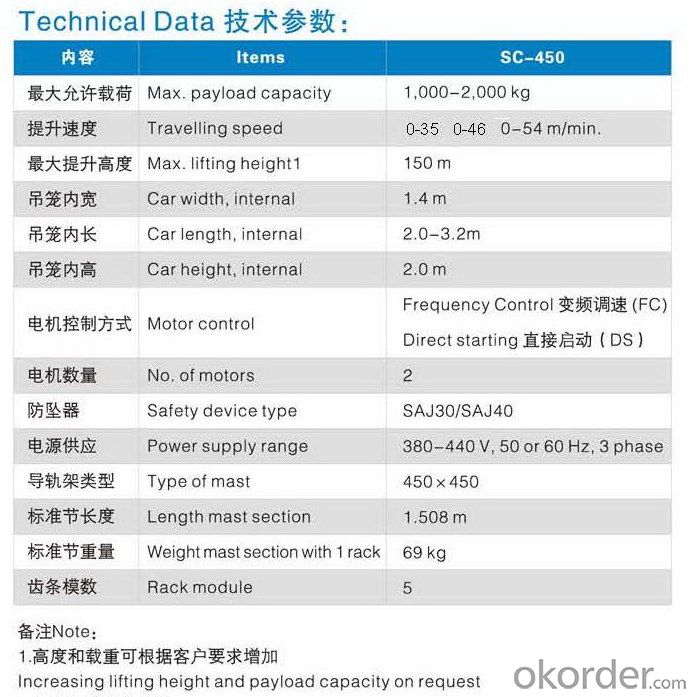

Specifications:

- Q: Is it possible to utilize a building hoist for lifting materials during demolition projects?

- <p>While a building hoist is typically designed for construction purposes to lift materials and personnel, it is not advisable to use it for demolition work. Demolition involves hazardous conditions with falling debris and unstable structures, which can compromise the safety and integrity of the hoist. Instead, specialized equipment like wrecking balls, hydraulic shears, and cranes are more suitable for demolition tasks. These are engineered to handle the heavy loads and unpredictable conditions associated with breaking down structures safely.</p>

- Q: What is the typical maintenance requirement for a building hoist?

- <p>The maintenance requirement for a building hoist can vary depending on the specific model and usage frequency. Generally, daily checks are needed to ensure safety, including inspecting cables, brakes, and the hoist mechanism. Monthly inspections should be conducted to check for wear and tear, and to lubricate moving parts. Annual inspections by a certified professional are often required to ensure compliance with safety standards and to perform more in-depth maintenance. Regular maintenance is crucial to prevent accidents and extend the lifespan of the hoist.</p>

- Q: What precautions should be taken when using lifting equipment to ensure safety?

- <p>Safety measures for lifting equipment include regular inspections and maintenance to ensure equipment is in good working order. Operators must be trained and certified for the specific equipment they are using. Safe lifting practices should be followed, such as never exceeding load limits, using the correct lifting points, and securing loads properly. Personal protective equipment (PPE) should be worn, and clear communication among the lifting team is essential. Additionally, a safe working environment should be maintained, free from obstructions and hazards, and emergency procedures should be in place and known by all involved.</p>

- Q: This question asks if single-rope lifts can experience malfunctions or create safety risks.

- <p>Yes, single-rope lifts can malfunction and pose safety hazards. Like any mechanical system, they are subject to wear and tear, component failure, and human error. Factors such as inadequate maintenance, poor weather conditions, and operator negligence can lead to malfunctions. Safety hazards may include rope breakage, sudden stops, or even derailment. However, modern lifts are equipped with multiple safety features such as emergency brakes and redundant systems to minimize these risks and ensure passenger safety. Regular inspections and adherence to safety protocols are crucial to prevent malfunctions and maintain the safety of single-rope lifts.</p>

- Q: Is it possible to use a building hoist for lifting light objects without any additional tools?

- <p>Yes, a building hoist can be used for lifting light objects without using any tools. Building hoists are designed to lift a variety of materials, including lighter items, within their weight capacity. However, it's crucial to ensure that the hoist is rated for the weight of the object and that safety protocols are followed to prevent accidents. Always consult the hoist's manual for specific guidelines on weight limits and safe operation procedures.</p>

- Q: This question asks for the method to determine the maximum weight that a building hoist can safely lift.

- <p>To calculate the weight limit of a building hoist, you must consider several factors: the hoist's mechanical capacity, the strength of the supporting structure, the load-bearing capacity of the cables or chains, and the safety regulations in place. Start by checking the manufacturer's specifications for the hoist's maximum load capacity. Then, ensure the hoist's supporting structure can withstand the weight and the force exerted during lifting. Inspect the cables or chains for any signs of wear and ensure they meet the required strength standards. Finally, adhere to local safety regulations, which often mandate a safety factor below the hoist's rated capacity to prevent overloading. Always consult with a professional engineer or the hoist manufacturer for precise calculations and safety guidelines.</p>

- Q: How does the elevator operate

- Responsible for operating elevator, maintenance, maintenance and safety. See what kind of elevator and workplace you are working on.

- Q: This question asks for an explanation of the functioning of hydraulic cylinders in lifting equipment.

- <p>Hydraulic cylinders in lifting equipment operate by converting hydraulic pressure into linear mechanical motion. They consist of a cylinder barrel, a piston, and a piston rod. When pressurized fluid is introduced into the cylinder, it pushes the piston, which in turn moves the piston rod. This movement is what lifts or moves the load. The force exerted by the piston is proportional to the pressure of the fluid and the area of the piston. The cylinder's design allows for controlled and precise lifting, making it ideal for heavy-duty applications where power and control are required.</p>

- Q: What precautions should be taken when using manual lifting equipment to ensure safety?

- <p>Safety measures for using manual lifting devices include inspecting equipment for damage before use, ensuring the load is within the device's weight capacity, using proper lifting techniques, maintaining a clear path for lifting, and securing the load to prevent shifting. Always wear appropriate personal protective equipment, such as gloves and safety shoes. Never exceed the rated capacity of the lifting device, and avoid sudden or jerky movements that could cause loss of control. Regular maintenance and training on safe lifting practices are also crucial to prevent accidents.</p>

- Q: Is it possible to utilize a building hoist for the purpose of raising construction materials or machinery?

- <p>Yes, a building hoist is specifically designed for lifting materials and equipment in construction settings. It is a temporary vertical transportation system used to move materials, tools, and sometimes personnel between different floors of a building under construction. Building hoists are essential for efficient construction processes, ensuring that materials are delivered to the correct levels without the need for manual labor, which can be time-consuming and hazardous.</p>

Send your message to us

Construction Hoist SC450 Series /Material Hoist /Building Hoist /Industrial Hoist /Lift /Elevator

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 20 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords