Construction Hoist SC650 Series /Material Hoist /Building Hoist /Industrial Hoist

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

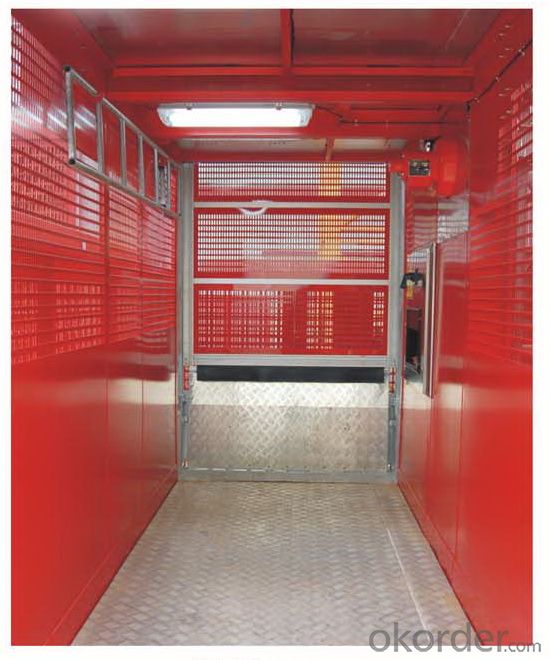

Our SC Construction Hoist is an industrial engineering elevator driven with pinion and rack, used for vertical transportation of materials, people and other heavy items, applicable to highrise building construction, storehouse, port, dock, tower, chimney and so on.

Features:

1. Modular design, easy to make different combinations according to specific requirement.

2. Can produce cage with length from 3.2m to 4.6m.

3. Adopting strong mechanic strength steel which makes light structure and large load capacity.

4. With many different models of cage door available. Aluminum structure, light weight and easy to open.

5. Both single cage and double cage are available. Fast and easy conversion between left and right cage.

6. Compact structure, convenient for transportation - can be directly packed into container.

7. Using gear to drive and brake, efficient and evergy saving.

8. Main components are hot dip galvanized which guarantee longer operational life.

9. Cable basket or cable guiding device with aluminum rail according to the requirement.

10. With frequency control and direct start available.

11. Advanced load inspection device, ensuring driving safety.

12. Meet European standard EN12159 and China standard GB/T10054.

Specifications:

- Q: This question asks for the method to adjust the tension of ropes or cables in lifting equipment such as a building hoist.

- <p>Adjusting the tension on ropes or cables in lifting equipment like a building hoist involves several steps. First, ensure the equipment is turned off and secured to prevent any accidents. Then, locate the tensioning mechanism, which could be a ratchet, turnbuckle, or a similar device. Gradually adjust the mechanism to tighten or loosen the cable as needed. Use a tension meter to measure the tension and ensure it meets the manufacturer's specifications. Regularly inspect the cables for wear and damage, and replace them if necessary. Always follow the equipment's manual for specific instructions and safety guidelines.</p>

- Q: Can a building hoist experience technical issues or fail to operate properly?

- <p>Yes, a building hoist can malfunction. Like any mechanical system, hoists are subject to wear and tear, component failure, and can be affected by human error. Malfunctions may include mechanical breakdowns, electrical faults, or safety device failures. Regular maintenance, inspection, and adherence to safety protocols can reduce the risk of hoist malfunctions.</p>

- Q: This question asks about the typical issues that can arise with building hoists, which are mechanical devices used in construction to lift materials and workers.

- <p>Common problems with building hoists include mechanical failures such as broken cables or chains, malfunctioning brakes, and worn-out gears. Electrical issues like short circuits or damaged control panels can also occur. Safety hazards may arise from improper installation or maintenance, leading to accidents. Overloading the hoist can cause structural damage and failure. Environmental factors like extreme weather conditions can affect performance and longevity. Regular inspections and maintenance are crucial to prevent these problems and ensure the safe operation of building hoists.</p>

- Q: What are the financial expenses associated with buying and keeping a building hoist in good condition?

- <p>The costs of purchasing and maintaining a building hoist include the initial purchase price, which can range from $10,000 to $50,000 depending on the hoist's capacity and features. Maintenance costs involve regular inspections, lubrication, and part replacements, averaging around $1,000 to $3,000 per year. Operating costs include labor for hoist operation and potential rental fees if the hoist is not owned. Additionally, there may be costs for safety training and compliance with regulations. These costs can vary widely based on the specific hoist model, usage frequency, and local regulations.</p>

- Q: This question asks about the measures taken to ensure that lifting equipment remains safe and functional in various weather conditions.

- <p>To ensure that lifting equipment is safe and reliable in all weather conditions, regular maintenance and inspection are crucial. Equipment should be designed with weather-resistant materials and should be tested periodically to withstand extreme temperatures, humidity, and precipitation. Protective covers or enclosures can be used to shield equipment from the elements. Additionally, training operators on the safe use of equipment in different weather conditions is essential. Emergency procedures should be in place for extreme weather events, and equipment should be regularly checked for wear and tear that could be exacerbated by weather conditions.</p>

- Q: Can a single lifting device accommodate variously shaped and sized objects?

- <p>Yes, a single lifting device can often be used to lift objects of different shapes and sizes, provided it has the necessary capacity and adaptability. Adjustable features, such as extendable arms, variable hooks, or specialized attachments, allow for a range of lifting capabilities. However, it's crucial to ensure that the device's weight limit is not exceeded and that it is safe and suitable for the specific object being lifted to avoid damage or accidents. Always refer to the manufacturer's guidelines for the safe operation and weight limits of the lifting device.</p>

- Q: Whether the construction elevator is a dual-purpose elevator

- The vertical transportation machinery in construction is mainly the material elevator and construction elevator. Material hoist can slide can't manned, suitable for multilayer use, construction elevator is used only for the top, both manned and can slide, in general the construction elevator for dual-use goods of choose and employ persons outside the elevator.

- Q: Is it possible to utilize a single-rope lifting system in the context of a building hoist?

- <p>Yes, a single-rope lifting system can be used in a building hoist. This system is common in construction elevators, where a single rope is used to lift and lower the hoist's cage. The rope is attached to a motor at the top and passes over sheaves or pulleys to provide mechanical advantage. It is essential to ensure that the rope is strong enough to support the load and that the system is equipped with safety features such as overload protection and emergency braking mechanisms to prevent accidents.</p>

- Q: What is the purpose of a building hoist and can it be utilized for lifting heavy objects that cannot be manually lifted?

- <p>Yes, building hoists are specifically designed to lift heavy objects that are beyond the capacity of manual lifting. They are essential in construction sites for moving materials such as bricks, cement, and steel beams to various levels of a building. Building hoists are engineered to handle significant weight and ensure the safe and efficient transport of materials, reducing the risk of injury and improving productivity on construction sites.</p>

- Q: This question asks for a description of the process of using a hydraulic cylinder in the context of a building hoist.

- <p>To use a hydraulic cylinder in a building hoist, first ensure the hoist is properly installed and secured. Connect the hydraulic cylinder to the hoist's power source, typically a hydraulic pump. The pump pressurizes hydraulic fluid, which is then directed into the cylinder. As the fluid enters, it pushes a piston within the cylinder, causing it to extend and lift the load. To lower the load, the fluid is released from the cylinder, allowing the piston to retract. Always monitor the pressure and ensure the system is leak-free for safe operation. Regular maintenance, including checking seals and lubricating parts, is crucial to prolong the life of the hydraulic cylinder and ensure efficient hoist performance.</p>

Send your message to us

Construction Hoist SC650 Series /Material Hoist /Building Hoist /Industrial Hoist

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords