Construction Hoist SC450 Series /Material Hoist /Building Hoist /Industrial Hoist

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

Our SC Construction Hoist is an industrial engineering elevator driven with pinion and rack, used for vertical transportation of materials, people and other heavy items, applicable to highrise building construction, storehouse, port, dock, tower, chimney and so on.

Features:

1. Modular design, easy to make different combinations according to the requirement.

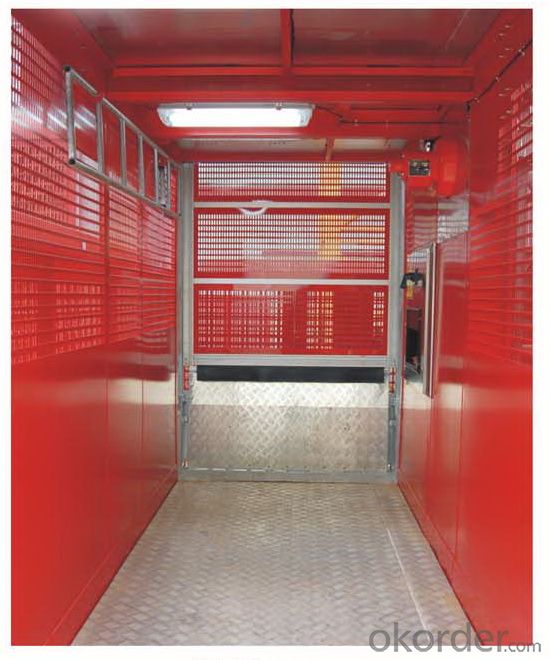

2. Can produce cage with length from 2.0m to 3.2m.

3. Adopting strong mechanic strength steel which makes light structure and large load capacity.

4. With many different models of cage door available. Aluminum structure, light weight and easy to open.

5. Both single cage and double cage are applicable. Fast and easy conversion between left and right cage.

6. Compact structure, convenient for transportation - can be directly packed into container.

7. Using gear to drive and brake, it is efficient and evergy saving.

8. Main components are hot dip galvanized which guarantee longer operational life.

9. Cable basket or cable guiding device with aluminum rail according to the requirement.

10. With frequency control and direct start available.

11. Advanced load inspection device, ensuring driving safety.

12. Accredited with European standard EN12159 and China standard GB/T10054.

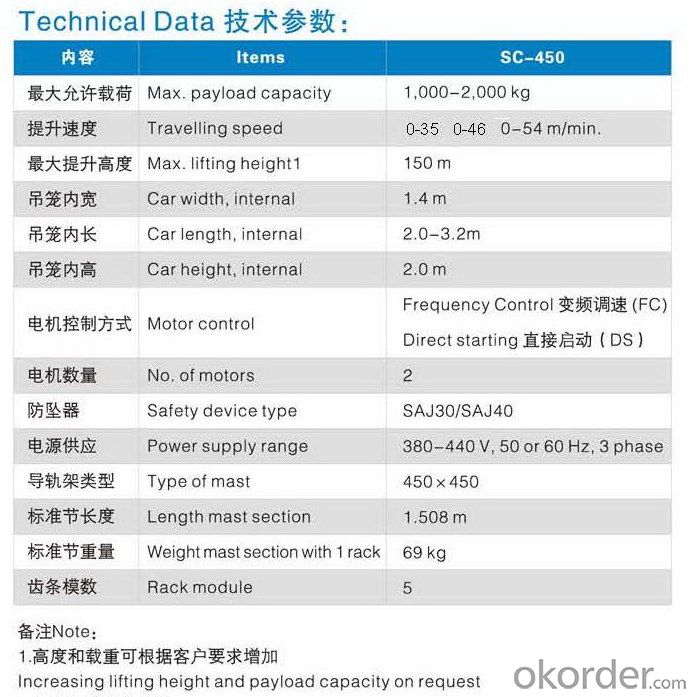

Specifications:

- Q: Is there any violation of the law after the construction elevator is scrapped?

- In principle, eight years; But for eight years has scrapped section standard of standard section pillar thickness wear to design thickness of 1/4 (like this value) will be scrapped or downgrade use; After eight years, the construction elevator can also be used, but the structural parts need to be broken and the test can be used again. The pendant safety device for the construction elevator is required to be tested every year for five years.

- Q: The staff on the construction platform shall not exceed the number of people

- Different models have different load rating and platform lift platform size, this depends, suzhou new aluminium alloy elevator, Lin professional aluminum alloy lift platform.

- Q: Is it possible to utilize a building hoist for the purposes of renovation projects?

- <p>Yes, a building hoist can be used for renovation work. These hoists are designed to lift and lower materials and personnel efficiently, making them ideal for construction and renovation projects. They help in moving heavy materials such as bricks, cement, and tools to different floors without the need for manual labor, thus increasing safety and productivity. However, it's crucial to ensure that the hoist is properly installed, maintained, and operated by trained personnel to avoid accidents and ensure the safety of all involved.</p>

- Q: This question asks about the procedures and practices for regularly maintaining and inspecting a building hoist to ensure its safe and efficient operation.

- <p>Regular maintenance and inspection of a building hoist are crucial for safety and efficiency. It involves daily checks before use, including visual inspections for any visible damage, proper functioning of safety devices, and ensuring the hoist is clean and free of debris. Weekly inspections should focus on the mechanical components, such as gears, cables, and brakes, and checking for any unusual noises or vibrations. Monthly inspections may include more in-depth checks of the electrical systems and the structural integrity of the hoist. Annual inspections typically involve a thorough examination by a certified professional, who will assess the overall condition and safety of the hoist, ensuring it complies with all relevant safety standards. Always follow the manufacturer's guidelines and local regulations for maintenance and inspection schedules.</p>

- Q: Does the building height not exceed 40 meters must install the construction elevator?

- There is no hard and fast rules, but the construction unit according to the time limit for a project, the delivery of materials, construction personnel and management personnel, including supervision, need to install the vertical transportation machinery (including goods dual-purpose ladder).

- Q: This question asks if building hoists are capable of moving large or heavy objects.

- <p>Yes, building hoists are specifically designed to move large and heavy objects vertically in construction settings. They are used to lift materials such as bricks, concrete, and steel beams to various levels of a building under construction. Building hoists are engineered to handle significant weight and are an essential tool for efficient material transport in tall structures where cranes may not be practical or safe for frequent use.</p>

- Q: Is it safe to use an electric lifting device indoors if it is not certified for indoor use?

- <p>It is not advisable to use an electric lifting device indoors if it is not certified for such use. Non-certified devices may not meet safety standards for indoor environments, including electrical safety, structural integrity, and risk of fire. Using uncertified equipment can lead to accidents, injuries, or property damage. Always ensure that any lifting equipment complies with local regulations and is suitable for the intended environment to maintain safety.</p>

- Q: Is it feasible to repair or replace a building hoist with ease?

- <p>The ease of repairing or replacing a building hoist depends on several factors. For minor issues, repairs can often be done relatively easily by trained technicians. However, for major malfunctions or when a hoist is outdated, replacement might be necessary. This process can be complex and requires expertise to ensure safety and compliance with building codes. Factors such as the hoist's age, the complexity of the system, and the availability of replacement parts play a significant role in determining the ease of repair or replacement. In some cases, it might be more cost-effective to replace rather than repair, especially if the hoist is old or if repair costs are high.</p>

- Q: This question asks whether it is safe to operate a building hoist in adverse weather conditions such as wind and rain.

- <p>The use of a building hoist in windy or rainy weather is generally not recommended due to safety concerns. Wind can cause instability and swaying of the hoist, while rain can lead to slippery conditions and electrical hazards. Most hoist manufacturers and safety guidelines advise against operating hoists in such conditions. However, if absolutely necessary, it should be done with extreme caution, following specific safety protocols, and ensuring all necessary weatherproofing and stability measures are in place. Always consult the manufacturer's guidelines and local regulations before operating a hoist in adverse weather.</p>

- Q: Should a fire extinguisher be equipped in the construction elevator?

- The dual-purpose construction elevator should be needed

Send your message to us

Construction Hoist SC450 Series /Material Hoist /Building Hoist /Industrial Hoist

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords