Construction Hoist SCD270 Counterweight Passenger Lifter

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Construction Hoist Description

Feature: Construction Hoist Condition: New Application: Construction

Payload(kg):2700 Lifting Speed(m/min):33 Motor Power(kw): 2*15

Safety Device: SAJ50-1.2 Cage: Single Counterweight: Yes

Certification: CE,ISO Place of Origin: China(Mainland) Model Number: Type:SCD270

Packaging & Delivery of Construction Hoist

Packaging Detail: Nude package Delivery Detail: 25-30days

Main Parts of Construction Hoist

● The gearing adopts imported bearing, enameled cable, and oil seal.

● The electric parts adopt products from world renowned manufactures such as Schneider, Siemens, and LG.

● The racks and pinion adopts special material and heat-treatment technique, which prolong the life of these parts.

● The steel structure uses quality steel from famous domestic manufactures.

● The surface of the structure can apply paint-spray, parkerozing baking finish or hot galvanizing processing according

to users requirements,

● The cage can be produced and decorated by aluminum molded board, punched-plate or figured aluminm board.

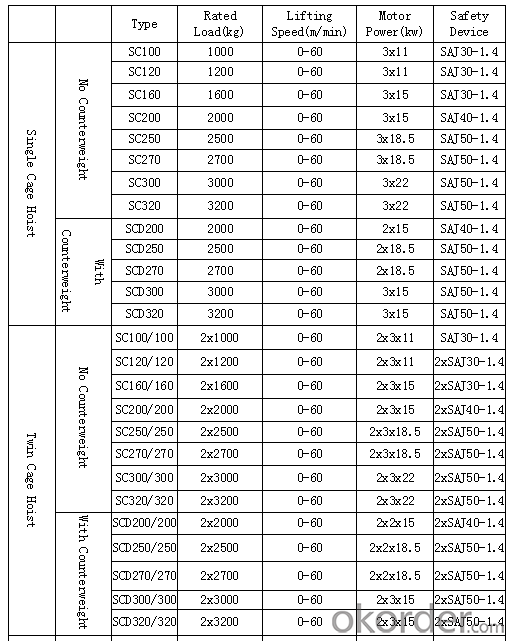

Construction Hoist Specifiction

FAQ of Construction Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide &

protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity

is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our

quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance

& exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.

- Q: Is it possible to utilize a building hoist for the purpose of lifting small tools and equipment?

- <p>Yes, a building hoist can be used for lifting small tools and equipment, provided it is within the hoist's weight capacity. It's important to ensure that the items are securely fastened to prevent any accidents during lifting. Always follow the manufacturer's guidelines and safety regulations when using a building hoist for any lifting tasks.</p>

- Q: This question seeks to understand the benefits and drawbacks associated with the use of hydraulic building hoists in construction.

- <p>Hydraulic building hoists offer several advantages, including high lifting capacity, smooth and controlled lifting, and lower maintenance costs due to fewer moving parts. They are also energy-efficient and can be easily integrated into existing systems. However, they have some disadvantages. For instance, they can be more expensive to purchase initially compared to other hoist types. Additionally, they may require more space for installation and can be sensitive to extreme temperatures, which might affect performance. Lastly, hydraulic systems can be prone to leaks and require regular fluid checks and maintenance to prevent system failure.</p>

- Q: What is the function or use of constructing a building hoist?

- <p>The purpose of building hoists is to facilitate the vertical transportation of materials, equipment, and sometimes personnel during the construction process. They are essential for moving heavy items to various floors or levels of a building under construction. Hoists enhance efficiency, reduce manual labor, and improve safety by minimizing the risk of accidents associated with manual handling of heavy loads. They are particularly crucial in high-rise construction where access is limited and the volume of materials to be moved is substantial.</p>

- Q: Is it possible to fix a building hoist or substitute it with alternative lifting machinery?

- <p>Yes, a building hoist can be repaired if the damage is not severe. If repair is not feasible or cost-effective, it can be replaced by other types of lifting equipment. There are various alternatives available, such as cranes, forklifts, and material hoists, each with its own advantages and suitable for different scenarios. The choice depends on factors like the weight of the load, the height of the building, and the specific requirements of the construction project. It's essential to consider safety, efficiency, and compatibility with the existing infrastructure when making such decisions.</p>

- Q: What is the main function of the construction elevator safety guard

- When the cage is unexpectedly overspeed, the cage will be stationary on the rail frame and cut off the power supply to ensure the safety of personnel and equipment.

- Q: Is it possible to use personal lifting equipment for lifting extremely heavy objects?

- <p>Using your own lifting equipment to lift very heavy objects can be possible, but it depends on the weight capacity and safety standards of your equipment. Always ensure that your lifting gear is rated for the weight you intend to lift and that it is in good working condition. Additionally, it's crucial to follow all safety protocols, including proper setup, securing the load, and using personal protective equipment. For extremely heavy objects, professional lifting services are often recommended to ensure safety and prevent accidents.</p>

- Q: Safety device for construction elevator

- Many 1, 2, upper and lower limit for safety device 3 TDD, extreme limit 4, buffer spring 5, has threshold position switch, single threshold position switch 7, 6 top and limit switch 8 TDD, enclosure door lock 9, lock line 10, has locks There are a lot of electrical safety protection

- Q: This question asks for an explanation of the functioning of hydraulic cylinders in lifting equipment.

- <p>Hydraulic cylinders in lifting equipment operate by converting hydraulic pressure into linear mechanical motion. They consist of a cylinder barrel, a piston, and a piston rod. When pressurized fluid is introduced into the cylinder, it pushes the piston, which in turn moves the piston rod. This movement is what lifts or moves the load. The force exerted by the piston is proportional to the pressure of the fluid and the area of the piston. The cylinder's design allows for controlled and precise lifting, making it ideal for heavy-duty applications where power and control are required.</p>

- Q: What precautions should be taken when using manual lifting equipment to ensure safety?

- <p>Safety measures for using manual lifting devices include inspecting equipment for damage before use, ensuring the load is within the device's weight capacity, using proper lifting techniques, maintaining a clear path for lifting, and securing the load to prevent shifting. Always wear appropriate personal protective equipment, such as gloves and safety shoes. Never exceed the rated capacity of the lifting device, and avoid sudden or jerky movements that could cause loss of control. Regular maintenance and training on safe lifting practices are also crucial to prevent accidents.</p>

- Q: Is it possible to replace an electric motor with a hydraulic cylinder in an electric-hydraulic lifting system?

- <p>No, a hydraulic cylinder cannot be used in place of a motor in an electric-hydraulic lifting system. A hydraulic cylinder is a component that converts hydraulic pressure into linear motion, while an electric motor converts electrical energy into mechanical energy. In an electric-hydraulic system, the motor drives a hydraulic pump, which generates the pressure needed to actuate the cylinder. The motor is essential for providing the power source, and the cylinder is the actuator that uses this power to perform work. Replacing the motor with a cylinder would result in a system without a power source, rendering it inoperative.</p>

Send your message to us

Construction Hoist SCD270 Counterweight Passenger Lifter

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords