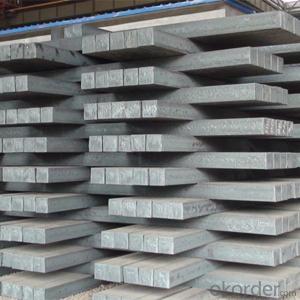

Construction 20# Rectangular hollow section/ RHS

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Name | rectangular hollow section/ RHS | |

Size | Size: | 10*10--500*500mm |

Thickness: | 0.45--16mm | |

Length: | 3-12m | |

Steel Grade | Q195,Q215,Q235,Q345,16Mn, 20# | |

Standard | ASTM A500,EN10219,GB/T6728,GB/T6725,JIS G3466 | |

Usage | 1. For Structure, Airport, Railway 2. Construction and so on. | |

Ends | Plain end or By Your Choice | |

Surface | Bared Or With Oiled Or Galvanized | |

Technique | ERW ,Hot Rolled and Cold Rolled | |

Section Shape | Rectangular | |

Inspection | With Hydraulic Testing, Eddy Current , Infrared Test | |

Package | Bags, Bundle, In Bulk, Containers | |

MOQ | 20 Metric Ton / Can Be Negotiated | |

Supply Ability | 15,000 Metric Ton/Month | |

Date of Delivery | 7 days(Qty within 1000 Metric Ton) or According To The Quantity | |

Port of Shipment | Tianjin, China | |

Payment | L/C T/T | |

- Q: What are the different methods of transporting steel pipes?

- The different methods of transporting steel pipes include using trucks, trains, ships, and pipelines. Trucks are commonly used for short-distance transportation, while trains and ships are used for long-distance transportation. In some cases, steel pipes can also be transported through pipelines, especially for oil and gas applications. Each method has its own advantages and considerations, such as cost, capacity, and accessibility.

- Q: What is the process of spiral steel tube production?

- X ray flaw detection: 100% X ray industrial television inspection of internal and external weld seams, and image processing system is adopted to ensure the sensitivity of flaw detection.8. press test: the steel pipe is tested by root test on the water pressure test machine to ensure the test pressure of the steel pipe to meet the standard requirement.9. chamfering flat head: the qualified steel pipe is processed at the end of the pipe to achieve the required size of the end of the pipe10. final inspection: ultrasonic and X ray inspection, and magnetic particle inspection at the end of pipe to check for welding problems and pipe end defects.11., marking: qualified steel pipe for oil, in order to prevent corrosion, and according to user requirements for marking.

- Q: How are steel pipes used in wastewater treatment?

- The wastewater treatment process relies heavily on the use of steel pipes. These pipes are crucial for the transportation and distribution of wastewater from various sources to the treatment facilities. The decision to use steel pipes is primarily based on their durability, strength, and resistance to corrosion. Within wastewater treatment plants, steel pipes are commonly applied for multiple purposes. Firstly, they are utilized for the intake of raw wastewater. These pipes are typically designed with a large diameter to accommodate the high flow rate of incoming wastewater. Due to their ability to withstand the pressure and turbulence caused by the wastewater flow, steel pipes are an ideal choice for this task. Once inside the treatment facility, steel pipes are responsible for the transportation of the wastewater to different treatment processes. They serve as connectors between various units, such as screens, grit chambers, sedimentation tanks, and biological reactors. Steel pipes are preferred for these applications because they can handle the corrosive elements present in wastewater, including chemicals, acids, and gases. Moreover, their durability ensures a long-lasting service life, resulting in reduced maintenance and replacement costs. Steel pipes also play a significant role in the distribution of treated water during the wastewater treatment process. After the wastewater has undergone treatment, it goes through disinfection and other processes to eliminate harmful contaminants. The treated water is then distributed through steel pipes, allowing it to be reused for purposes such as irrigation, industrial processes, or discharged back into water bodies. Furthermore, steel pipes are employed in the construction of wastewater treatment infrastructure. They are used in the installation of underground sewer lines, pumping stations, and manholes. Steel pipes provide the necessary strength and stability to withstand external forces like the weight of the soil. To summarize, steel pipes are crucial components in the wastewater treatment process. They are responsible for the transportation and distribution of wastewater, connecting different treatment units, and distributing treated water. Their durability, resistance to corrosion, and ability to handle high-pressure flows make them an excellent choice for this demanding application.

- Q: Can steel pipes be insulated for thermal efficiency?

- Steel pipes can indeed be insulated to enhance their thermal efficiency. By insulating steel pipes, heat loss or gain can be minimized, depending on the specific purpose. Typically, the insulation material is wrapped around the pipes, creating a protective barrier. This barrier effectively prevents heat transfer between the pipes and the surrounding environment. As a result, the energy required to heat or cool the fluid flowing through the pipes is significantly reduced, leading to improved energy efficiency. This practice is widely employed in industries such as HVAC, oil and gas, and industrial processes, where precise temperature control is crucial. Moreover, insulation also serves to prevent condensation and corrosion on the outer surface of the pipes. All in all, insulating steel pipes is a cost-effective measure that enhances thermal efficiency and reduces energy consumption.

- Q: Can steel pipes be used for mining applications?

- Indeed, mining applications do permit the utilization of steel pipes. The mining industry frequently employs steel pipes for diverse objectives. Specifically, they are commonly utilized for the conveyance of fluids, such as water or slurry, during mining operations. Steel pipes possess remarkable attributes, including durability, strength, and resistance to corrosion, rendering them suitable for the demanding and corrosive underground mining environments. They have the ability to endure high pressure and effectively manage the substantial loads associated with mining applications. Furthermore, the ease with which steel pipes can be welded and connected facilitates efficient installation and maintenance. Considering all factors, steel pipes prove to be a reliable and economically sound option for mining applications.

- Q: What are the specifications for steel pipes used in high-pressure applications?

- The specifications for steel pipes used in high-pressure applications typically include factors such as material composition, wall thickness, diameter, and pressure rating. These pipes are often made from strong and durable steel alloys, such as carbon steel or stainless steel, to ensure their ability to withstand high pressures. The wall thickness and diameter of the pipe are carefully selected to handle the specific pressure requirements of the application. Additionally, the pipes may need to meet certain industry standards, such as ASTM or ASME codes, to ensure their quality and performance in high-pressure environments.

- Q: What are the main aspects of precision steel tubes?

- Precision tube is a kind of seamless steel tube with high precision and high brightness produced by cold drawing or cold rolling.

- Q: How do you prevent steel pipes from freezing in cold climates?

- To prevent steel pipes from freezing in cold climates, it is important to insulate the pipes properly. This can be done by wrapping them with insulation sleeves or foam, which helps to retain heat and prevent rapid temperature changes. Additionally, ensuring that there is proper ventilation in the area where the pipes are located can help to maintain a higher temperature and prevent freezing.

- Q: What are the different types of steel pipes?

- There are several different types of steel pipes, including seamless pipes, welded pipes, galvanized pipes, and stainless steel pipes.

Send your message to us

Construction 20# Rectangular hollow section/ RHS

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords