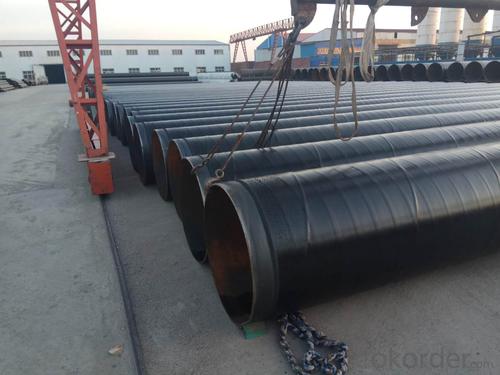

Composite Strengthening Grade 3PE Anticorrosion Gas Pipeline 3PE Anticorrosion Steel Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 655 m²

- Supply Capability:

- 15000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

3PP anticorrosion: pipeline three layer PP corrosion protection structure: the first layer of epoxy powder (FBE50 to 100um), two layers of adhesive (AD) 250 ~ 400um, three layers of polypropylene (PP) 1.4 ~ 4.0mm. The three materials are integrated into one, and are firmly combined with the steel tube to form a good anticorrosive coating. The temperature of the anticorrosive coating can reach 110 degrees.

Diameter range from 60 to 1420GB/T23257-2009

The upper and lower limits of the thickness of the film. According to the regulation of table 2.0.2 in the SY/T0413-2002 standard, it is 170-250 u m, and this thickness is not a problem for the circular mold coating line. For the winding operation line, this thickness can not guarantee the actual grafting glue of the 3PE anticorrosion adhesive in our country. The copolymer is actually a 3PE anti-corrosion first band adhesive. The product of acrylic anhydride grafting, so it should be called graft adhesive more appropriate; the current industry standard SY / T0413-2002 four items of confocal tar. The adhesive wrapped in epoxy powder on the middle of the steel tube is beneficial to the adhesion between the steel pipe and PE.

Polyethylene is mainly high density polyethylene (HDPE), and the softening point of VEKA is not less than 110 C, and the thickness of the high temperature area not more than 220 degrees is determined by the German standard DIN30670-1991, which is mainly low and medium density polyethylene. The impact strength of 3PE anticorrosion layer is greatly improved and the quality of pipeline construction is guaranteed. SY/T0413-2002 also greatly improves the peeling strength and impact resistance of the 3PE anticorrosion layer, and clearly stipulates the carbon black content of some special materials, which ensures the mechanical strength and the touch performance of the 3PE anticorrosion layer, and increases the peeling strength of the patch. (i.e. the peeling strength of primer steel with heat shrinkage sleeve and heat shrinkage belt) sampling frequency has contributed to guaranteeing the quality of external anticorrosive coating of pipeline.

- Q: Can composite pipes be used for carbon capture and storage systems?

- Yes, composite pipes can be used for carbon capture and storage systems. Composite materials, such as fiber-reinforced polymers, offer several advantages for this application, including high strength-to-weight ratio, corrosion resistance, and thermal stability. These properties enable composite pipes to effectively transport and store captured carbon dioxide, contributing to the overall efficiency and safety of carbon capture and storage systems.

- Q: Are composite pipes suitable for use in high-pressure applications?

- Yes, composite pipes are suitable for use in high-pressure applications. Composite pipes are made of materials such as fiberglass, carbon fiber, or reinforced plastics, which provide excellent strength and durability. These pipes can withstand high pressures and are resistant to corrosion, making them a reliable choice for high-pressure applications in various industries such as oil and gas, chemical, and water distribution.

- Q: Do composite pipes require insulation in hot climates?

- Yes, composite pipes typically require insulation in hot climates. Insulating the pipes helps to prevent heat transfer, which can reduce energy losses and maintain the desired temperature of the fluid being transported.

- Q: Is the plastic lined steel pipe the same as the PSP composite pipe?

- Lined with plastic steel composite pipe is the plastic through the paste on the steel, and personally feel a little better PSP it, lining the diameter of the impact of relatively large.

- Q: Construction technology of internal and external double hot melt joint of PSP steel plastic composite pipe

- Mark the outer weld depth with the marking plate and marker pen at the end of the pipe according to the requirement of the technological parameter table.

- Q: What is the pressure rating of a composite pipe?

- The pressure rating of a composite pipe can vary depending on the specific materials used and the design of the pipe. Composite pipes are typically designed to withstand high pressures and are commonly used in applications where high pressure is a concern. It is important to refer to the manufacturer's specifications and guidelines to determine the exact pressure rating of a specific composite pipe.

- Q: Do composite pipes have any environmental benefits?

- Yes, composite pipes have several environmental benefits. Firstly, they are lightweight compared to traditional metal pipes, reducing transportation costs and associated carbon emissions. Secondly, composite pipes are resistant to corrosion and chemical degradation, resulting in longer lifespan and less frequent replacements, reducing waste generation. Additionally, composite materials are often recyclable, offering the potential for a more sustainable end-of-life solution. Overall, composite pipes contribute to a greener and more sustainable infrastructure.

- Q: Can composite pipes be used for oil and gas well drilling?

- Yes, composite pipes can be used for oil and gas well drilling. Composite pipes are made from materials such as fiberglass, carbon fiber, or other reinforced polymers, which offer excellent corrosion resistance and high strength-to-weight ratio. These pipes are capable of withstanding high pressures and harsh environments, making them suitable for drilling applications in the oil and gas industry. Additionally, composite pipes have the advantage of being lightweight, which simplifies transportation and installation processes.

- Q: Hot galvanized steel (PE Village plastic) composite pipe and PE100 water supply pipe (sdr11) what is different, we usually talk about steel pipe refers to that?

- Hot galvanized steel (PE Village plastic) composite pipe and PE100 water supply pipe is not the same, we usually talk about steel pipe, refers to hot galvanized steel (inner Village plastic) composite pipe or plastic pipe outsourcing. PE100 water supply pipe is a single layer of plastic pipe, but the material grade is different.

- Q: How long do composite pipes typically last?

- Composite pipes typically have a lifespan of 50 to 100 years, depending on the specific materials used and the conditions they are exposed to.

Send your message to us

Composite Strengthening Grade 3PE Anticorrosion Gas Pipeline 3PE Anticorrosion Steel Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 655 m²

- Supply Capability:

- 15000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches