Natural gas pipeline 3pe anti-corrosion steel pipe manufacturers

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 443 m²

- Supply Capability:

- 56655 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

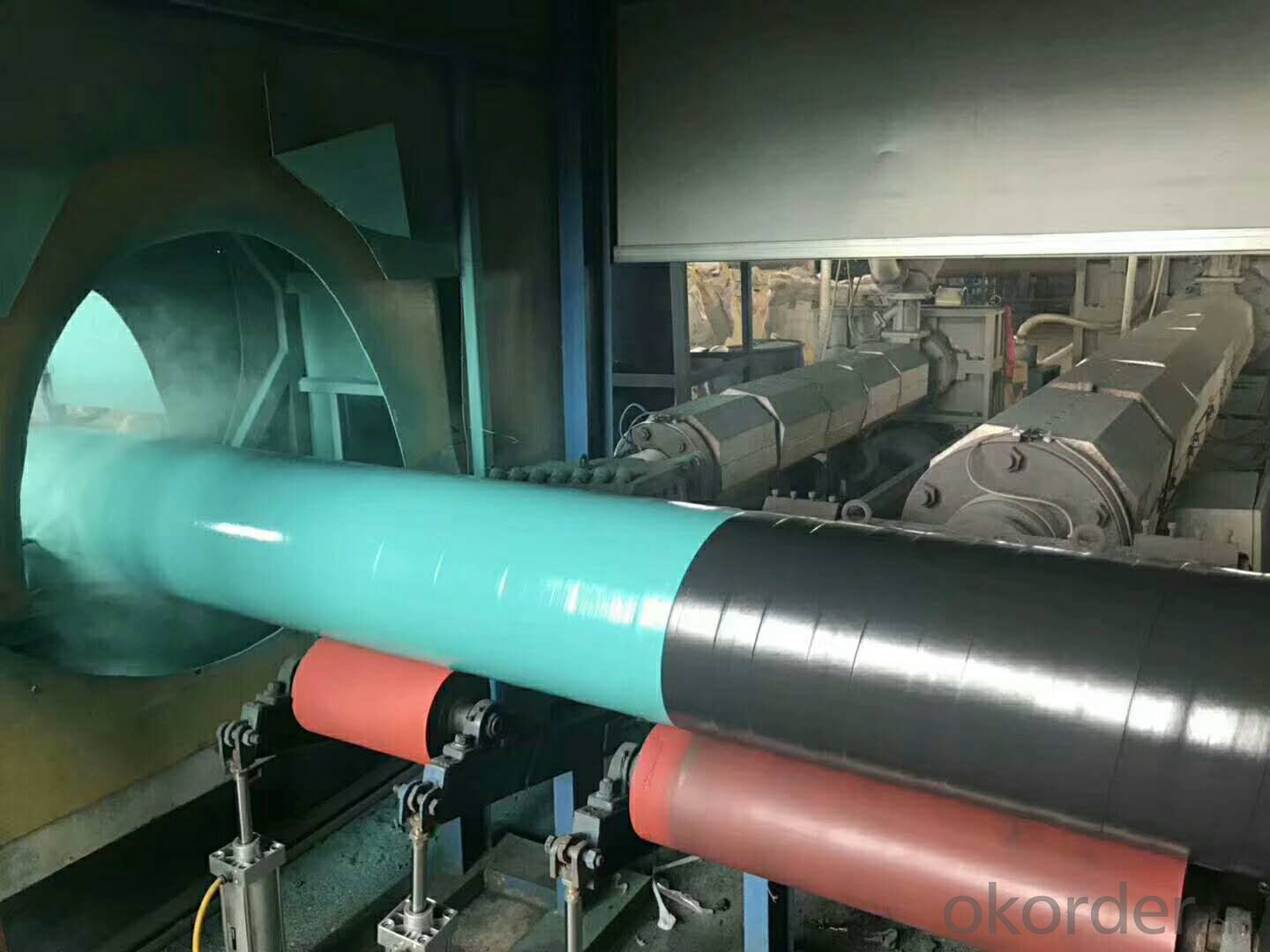

3 PE anticorrosive pipe

The 3PE epoxy powder composite steel pipe (also known as TPEP anti-corrosion pipe) is an upgrade product on the basis of the epoxy composite steel pipe in the outer polyethylene, which is the most advanced anti-corrosion form of buried long distance pipeline at present. The self-developed fourth-generation large-diameter pipeline's new anti-corrosion outer wall adopts thermal fusion and winding process to form a three-layer structure anti-corrosion layer with the bottom epoxy resin, the middle adhesive and the outer polyethylene. The inner wall adopts thermal spraying epoxy powder for anti-corrosion, and the powder is evenly coated on the surface of the pipe body after being heated and melted at high temperature. At the same time, it has high strength of epoxy, low water absorption of PE and good softness of hot melt adhesive, with high anti-corrosion reliability.

1 at the end of glue. Before extruding the polyethylene coating, a sealing rubber layer should be applied to the pipe surface. The performance index of base gum is based on the hot melt adhesive of asphalt type used before. National standards on the base of the softening point, heating loss, needle penetration, thermal decomposition temperature, self-repair, shear strength, peel strength, and so on. However, it is proved that the adhesive still has many disadvantages, such as low temperature resistance and poor bonding performance. Some foreign people use butyl glue and the latest resin glue, and domestic base glue is one of the key research topics.

2 polyethylene. The density of polyethylene can range from 0, 91 to 0, 96g /c. The performance is different because of the different densities. Since there is no short bifurcation in high density polyethylene, its junction bii, degree, secondary strength, fracture rate, tear strength, drug resistance is much better than low density polyethylene, which can produce corrosion coatings with different properties and different prices according to the needs of users. High density polyethylene coated pipe (Huang Jiake) the applicable temperature below so ℃, bottom density polyethylene coated pipe (green jacket) the applicable temperature below 60 ℃.

3. Production method. Polyethylene anticorrosive coating used flow dipping process and powder dispersing and melting process, etc. Recently, the production method is basically extrusion method. Bibian of small diameter (15-800mm) is the adhesive circular mould method (with protective layer), and bibian of human diameter (400-1600mm) is the tight t-mould method (no protective layer, single layer). Recently, the use of close - fitting method on small and medium diameter pipe is increasing gradually. In the future, this method may be widely used on anti-corrosion steel pipe

- Q: How are steel pipes used in the infrastructure development?

- Steel pipes are widely used in infrastructure development for various purposes. They are commonly used for transporting water, oil, and gas, as well as for drainage systems and sewage networks. Steel pipes are also used in the construction of bridges, buildings, and highways, providing structural support and stability. Additionally, steel pipes are utilized in underground utilities, such as telecommunications and electrical systems. Their durability, strength, and resistance to corrosion make steel pipes a crucial component in infrastructure development.

- Q: What are the different methods of pipe lining for steel pipes?

- Some of the different methods of pipe lining for steel pipes include slip lining, cured-in-place pipe lining (CIPP), pipe bursting, and sliplining. Slip lining involves inserting a smaller diameter pipe into the existing steel pipe, while CIPP involves inserting a resin-impregnated liner into the pipe and curing it in place. Pipe bursting involves breaking the existing steel pipe and replacing it with a new pipe, while sliplining involves inserting a new pipe into the existing steel pipe without breaking it.

- Q: What is the impact of steel pipe size on flow rate and pressure?

- The steel pipe size has a significant impact on both the flow rate and pressure. A larger pipe size allows for higher flow rates by reducing the frictional losses, resulting in increased fluid velocity. This leads to higher pressure drops across the pipe due to the increased surface area exposed to the flowing fluid. Conversely, a smaller pipe size restricts the flow, causing higher pressure drops and lower flow rates. Therefore, selecting an appropriate pipe size is crucial to ensure optimal flow rates and pressure levels in a system.

- Q: How are steel pipes used in the aerospace industry?

- The aerospace industry extensively utilizes steel pipes for various purposes. Aircraft frames heavily rely on steel pipes as they offer the necessary strength and structural integrity. Steel pipes find applications in the fuselage, wings, and landing gear of airplanes, as well as in rocket launch vehicles and space shuttles. The aerospace industry favors steel pipes due to their exceptional strength-to-weight ratio. They possess lightweight properties while maintaining immense strength, enabling the construction of robust and dependable aerospace structures. This aspect proves crucial in the industry as weight reduction significantly improves fuel efficiency and overall performance. Steel pipes also serve the purpose of transporting fluids and gases within aircraft systems. They commonly operate in the hydraulic and fuel systems, facilitating the flow of vital fluids like hydraulic fluid, fuel, and coolant. By ensuring the safe and efficient movement of these fluids throughout the aircraft, steel pipes contribute to its proper functioning and performance. Furthermore, steel pipes find utility in the aerospace industry for heat transfer applications. They form an integral part of the aircraft's cooling systems, aiding in the dissipation of heat generated by engines, electrical components, and other systems. With their exceptional thermal conductivity, steel pipes effectively transfer heat away from critical areas, preventing overheating. In conclusion, steel pipes possess a crucial role in the aerospace industry. They contribute to aircraft construction by providing strength and structural integrity, as well as facilitating fluid and gas transportation and heat transfer. The utilization of steel pipes in the aerospace industry ensures the safety, efficiency, and reliability of aerospace structures and systems.

- Q: What are the safety precautions while working with steel pipes?

- Some safety precautions while working with steel pipes include wearing appropriate personal protective equipment such as gloves, safety glasses, and steel-toed boots to prevent injuries. It is important to ensure the work area is clear of any obstacles or tripping hazards. Workers should be trained in proper lifting techniques to prevent strain or back injuries. Additionally, it is crucial to follow proper procedures for handling and storing steel pipes to prevent accidents and maintain a safe working environment.

- Q: What are the factors affecting the cost of steel pipes?

- There are several factors that can affect the cost of steel pipes. Some of the main factors include the price of raw materials, such as iron ore and coal, which are used in the steel manufacturing process. Additionally, the cost of labor, transportation, and energy can also impact the overall cost of steel pipes. Market demand and competition within the industry can also influence prices. Finally, factors such as government regulations, trade policies, and currency exchange rates can also play a role in determining the cost of steel pipes.

- Q: How do you calculate the pipe flow rate for steel pipes?

- To calculate the pipe flow rate for steel pipes, you will need to consider various factors. Firstly, determine the inside diameter of the pipe, typically denoted as D. Next, measure the length of the pipe, denoted as L. Additionally, you will need to know the pressure drop, ΔP, across the pipe and the fluid density, ρ. Once you have this information, you can use the Darcy-Weisbach equation or the Hazen-Williams equation to calculate the flow rate. The Darcy-Weisbach equation is commonly used for pipes with turbulent flow, while the Hazen-Williams equation is often used for pipes with laminar flow. For the Darcy-Weisbach equation, the formula is: Q = (π/4) * D^2 * √(2ΔP/ρ) Where Q is the flow rate in cubic meters per second, D is the inside diameter of the pipe in meters, ΔP is the pressure drop across the pipe in pascals, and ρ is the fluid density in kilograms per cubic meter. For the Hazen-Williams equation, the formula is: Q = C * (D^2.63) * (ΔP^0.54) * (L^0.63) Where Q is the flow rate in cubic meters per second, D is the inside diameter of the pipe in meters, ΔP is the pressure drop across the pipe in pascals, L is the length of the pipe in meters, and C is the Hazen-Williams coefficient which depends on the roughness of the pipe. To accurately calculate the pipe flow rate, it is important to ensure that the units of measurement are consistent throughout the calculation. Additionally, it is crucial to have accurate measurements of the inside diameter, length, pressure drop, and fluid density to obtain reliable results.

- Q: Can steel pipes be used in marine environments?

- Indeed, the usage of steel pipes is viable in marine environments. Steel, being a robust and sturdy material, possesses the capability to endure the severe conditions prevalent in marine surroundings, encompassing saltwater exposure, wave impacts, and corrosion. Nevertheless, it is imperative to meticulously choose the appropriate steel variant and implement suitable protective measures to avert corrosion. Stainless steel and corrosion-resistant alloys are often employed in marine applications due to their exceptional resistance against corrosion and ability to withstand continuous saltwater exposure. Furthermore, the application of coatings such as epoxy or zinc can be an effective means of fortifying steel pipes against corrosion. Consistent maintenance and inspections are also pivotal in ensuring the durability and functionality of steel pipes in marine settings.

- Q: What are the different types of steel pipe supports for offshore platforms?

- There are several different types of steel pipe supports used for offshore platforms, including pipe racks, pipe clamps, pipe hangers, and pipe saddles. Pipe racks are used to support multiple pipes and provide a structure for them to rest on. Pipe clamps are used to secure individual pipes to structures or walls. Pipe hangers are used to suspend pipes from overhead structures, while pipe saddles are used to support pipes on horizontal surfaces. These different types of supports are designed to ensure the stability and integrity of the pipes in offshore environments.

- Q: How are steel pipes used in the construction of water treatment plants?

- Steel pipes are widely used in the construction of water treatment plants due to their numerous advantages and suitability for this specific application. These pipes are utilized in various ways to ensure the efficient and reliable functioning of water treatment facilities. Firstly, steel pipes are commonly used in the transportation of water from its source to the treatment plant. They are highly durable and can withstand high pressure, ensuring the safe and secure delivery of water over long distances. Steel pipes are also resistant to corrosion, which is crucial in preventing contamination of the water supply. Within the treatment plant, steel pipes are used in the distribution system to transport water to different treatment processes. They are often laid underground or within the facility's infrastructure, ensuring a seamless flow of water between different treatment units. Steel pipes are known for their high strength and structural integrity, making them suitable for this purpose. Furthermore, steel pipes are used in the construction of various water treatment equipment. For instance, they are utilized in the construction of sedimentation tanks, where water is allowed to settle, and impurities are removed. Steel pipes are also used in the construction of filtration systems, where water passes through different layers of filters to remove contaminants. Another important application of steel pipes in water treatment plants is in the construction of pumping stations. These stations are responsible for maintaining the water flow throughout the treatment process. Steel pipes are employed in the design and construction of the pumping systems to ensure the efficient movement of water between different stages of treatment. In summary, steel pipes play a crucial role in the construction of water treatment plants. They are used for the transportation of water, distribution within the facility, construction of treatment equipment, and in the design of pumping stations. Their durability, resistance to corrosion, and high strength make them an ideal choice for this critical infrastructure.

Send your message to us

Natural gas pipeline 3pe anti-corrosion steel pipe manufacturers

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 443 m²

- Supply Capability:

- 56655 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords