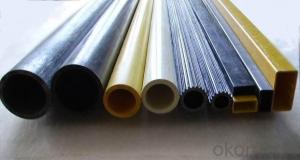

Composite FRP Rods, Tubes, Insulation, FRP Channel, Fiberglass Pipes

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 80000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

FRP rods and tubes are manufactured by high-strength fiberglass as reinforcing material, thermosetting resin as the base, and then taken shape on a special pultruded mold, where the high temperature activates the resin to cure.

Pultruded grating is made by a particular assembly process, which using “I” shape as its main load-bearing and special rod to go through the bearing bar. Pultruded grating include the standard grating and the custom grating, the custom grating can be designed to meet customer’s requirement or special using condition by changing the shape, size and space of the bearing bars, the surface can be covered with lozenge panel, grit panel, or added the anti-slippery sand directly.

FRP pultruded grating has the most characteristics of molded grating, but it has its distinct advantages, it has very high fiberglass content in the loading direction, so it has very high load capability, it has more superiority when used at wide span, so that the basic support will be decreased and the project cost will be reduced accordingly.

FEATURES

1. High anti-corrosion capability, long designed service time of 20 years;

2. Good hydraulic property, smooth inner surface with absolute roughness of 0.01mm, which is far less than that of carbon steel pipe or cast iron pipe;

3. Lightweight and facility to install and transport;

4. High specific intensity and reliable mechanical performance;

5. Low thermo-conductivity and small thermo-stress, which are allowed to be used in various conditions: exposed buried or suspended, in ocean or in deserts, freezing or humid;

DETAILED PARAMETER TABLE

Normal size | φ32*φ26, φ32*φ27.5, φ32*φ28, φ32*φ22, φ31*φ25,φ30*φ26, φ30*φ24, φ28*φ24, φ28*φ22, φ25.4*φ20.5, φ25.4*φ18.4, φ24*φ20, φ22*φ18.4 |

Surface effect | nexus mat surface, continuous strand mat surface, stitched mat surface, painting surface, wood texture surface |

Regular Color | yellow, red, blue, green, white, gray |

PICTURES

- Q: Winding method of glass fibre reinforced plastic pipeline anticorrosive glass fiber cloth

- When the length and width of glass fiber mesh are not enough, the method of lap joint must be adopted to improve the tangential bearing capacity of the joint, so as to effectively overcome the radial tensile stress, bending force and bending shear stress. The lap length of the glass fiber cloth at the joint is generally 50 to 100mm, and the joint of each glass fiber cloth should be at a certain distance from the adjacent joint. The longitudinal and transverse joints between adjacent layers shall be greater than 300mm, and the distance from the same seam shall not be less than 500mm.5) paste made of circular duct, glass cloth along the radial 45 degree angle to the direction of cut cloth; conical paste products, according to the fan-shaped cloth.

- Q: Is the installation of FRP pipes required qualification?

- However, some industries may have corresponding requirements, and some owners may also require it. For example, apply fiberglass pipes to shipyards

- Q: FRP pipe and 0.7 thick galvanized pipe which cost is low?

- The best material in glass steel mould rubber production 20 years, customers in all aspects

- Q: The outer thermal protection layer of the pipeline is made of GFRP. Which guy knows the construction method?

- One is to finish insulation wrap (Qin material cloth) and then wrapped a layer of glass paper....... The other is a glass lined steel pipe outside the pipe and then foamed and insulated inside

- Q: Which is better, PVC pipe and GRP pipe?!

- Of course, FRP pipe, high strength, aging resistance, PVC too crisp

- Q: Galvanized steel sheet and inorganic glass fibre reinforced plastic pipe are calculated according to this norm or norm

- The use of a fixed fare set without further consideration to duct losses has been included in the quota project

- Q: What are the specifications of glass fibre reinforced plastic cable pipes? What are they?

- FRP cable pipe is a new type of composite material, it mainly resin as adhesive, glass fiber as reinforcing agent, quartz sand as the supplementary material, formed by microcomputer control winding machine manufacturing, it has the strength of resistance to high pressure, weight, easy installation, safe and reliable, strong performance of insulation, corrosion can be anti corrosive the items, the anti parameter Water Leakage ability, but also has the advantages of long service life, can reach more than 50 years, because the FRP cable protection pipe set has various advantages of the industry, the performance has exceeded the same industry plastic pipe performance, it becomes popular industry engineering personnel.

- Q: How is the glass reinforced septic tank and the cement drain pipe connected?

- Very simple, ah, first install the septic tank, and then drain the pipe ah!

- Q: What kind of material are the flanges and valves on the GRP pipe?

- Construction: glass fiber reinforced plastic can be threaded joints, easy to install, better quality, PVC generally glue adhesive, due to temperature problems, quality is difficult to ensure;

- Q: What is the compressive strength of all kinds of FRP materials?

- Heat resistance, frost resistance: at -30 DEG C, still has good toughness and high strength, can be used for a long time in the range of -50 DEG C 80 DEG C, the temperature of resin with special formula can be more than 110 DEG C. 4) of light weight, high strength, convenient transportation and installation by fiberglassreinforcedplastic pipe winding fiber production, the proportion of 1.65 - 2, 1 / 4 only of steel, but the glass steel hoop tensile strength is 180 300MPa, the axial tensile strength of 60 150MPa, similar to alloy steel. Therefore, its specific strength (strength / density) is 2-3 times that of alloy steel, so that it can be designed according to different requirements of users to meet all kinds of internal and external pressure requirements of the pipeline. For the same diameter of single FRP tube, only carbon steel (steel plate) 1 / 2.5, 1 / 3.5 of the cast iron pipe, about 1 / 8 of prestressed reinforced concrete pipe, so the transportation is very convenient for installation. The GRP pipe is 12 meters per length, and can be reduced by 2/3 from the concrete pipe. The socket connection mode of the utility model has the advantages of quick and simple installation, low hoisting cost and improved installation speed. 5) small friction resistance, high transport capacity: glass tube wall is very smooth, roughness and friction resistance is very small. The roughness coefficient is 0.0084, while the n value of concrete pipe is 0.014, and the cast iron pipe is 0.013. Therefore, glass fiber reinforced plastic pipe can significantly reduce the loss of fluid pressure along the course and improve the conveying capacity.

Send your message to us

Composite FRP Rods, Tubes, Insulation, FRP Channel, Fiberglass Pipes

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 80000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords