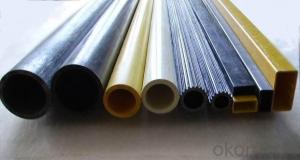

High Quality Composite Fiber Glass FRP Pipe Rod

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

FRP Fitting, a wide range of fittings as elbows, reducers, tees, caps, flanges etc. is available.

Fittings are manufactured by the hand lay-up, contact molding and spray-up process. In hand lay-up and contact molding processes veil and alternate layers of mat and woven roving saturated with resin are applied on the mold. In spray-up process continuous strand roving is fed through a chopper gun, combined with catalyzed resin, and sprayed onto the mould surface.

CHARACTERISTICS

High anti-corrosion capability, long designed service time of 20 years;

2. Good hydraulic property, smooth inner surface with absolute roughness of 0.01mm, which is far less than that of carbon steel pipe or cast iron pipe;

3. Lightweight and facility to install and transport;

4. High specific intensity and reliable mechanical performance;

5. Low thermo-conductivity and small thermo-stress, which are allowed to be used in various conditions: exposed buried or suspended, in ocean or in deserts, freezing or humid;

6. Less joints and rapid assembly design: According to concrete engineering conditions, there are a several

ways of connection designed for clients to choose, which include Adhesive-bonded Plug Joint, Adhesive-

bonded End-to-end Joint, Flange Joint, Plug Joint with O-ring Gasket(with key-lock) and Thread Joint etc.

7. Good electrical insulation

8. Not rust, rot or corrode, not permeate, and without consequent pollution;

9. Anti-furring and vermiculate resistance;

10. Flexible design: the pipe can be designed on the shape and function according to its conditions of usage.

TECHNICAL DATA

Thickness (mm) | Bar width (mm) | Open space (mm) | Open rate (%) | Approx weight (kg/m 2 ) |

25.4 | 15.2 | 22.8 | 60 | 13.2 |

25.4 | 15.2 | 15.2 | 50 | 15.9 |

25.4 | 15.2 | 10.1 | 40 | 18.5 |

25.4 | 40 | 10.8 | 21 | 14.5 |

38.1 | 15.2 | 22.8 | 60 | 15.8 |

38.1 | 15.2 | 15.2 | 50 | 19.1 |

38.1 | 15.2 | 10.1 | 40 | 22.4 |

50.8 | 25.4 | 25.4 | 50 | 16.6 |

50.8 | 25.4 | 12.7 | 33 | 21.1 |

PICTURES

- Q: Winding method of glass fibre reinforced plastic pipeline anticorrosive glass fiber cloth

- When the length and width of glass fiber mesh are not enough, the method of lap joint must be adopted to improve the tangential bearing capacity of the joint, so as to effectively overcome the radial tensile stress, bending force and bending shear stress. The lap length of the glass fiber cloth at the joint is generally 50 to 100mm, and the joint of each glass fiber cloth should be at a certain distance from the adjacent joint. The longitudinal and transverse joints between adjacent layers shall be greater than 300mm, and the distance from the same seam shall not be less than 500mm.5) paste made of circular duct, glass cloth along the radial 45 degree angle to the direction of cut cloth; conical paste products, according to the fan-shaped cloth.

- Q: FRP duct material plan is how to mention?

- Multi plan square, but also according to the combination of site and construction drawings, to see how much

- Q: Are FRP pipes still developing?

- I graduated last year and like you, stay two months left, glass steel pipeline buried pipe still have comparative advantages, but in Chinese, the quality of the products before this, after all, as the steel pipe is reliable, now doing chemical, water treatment, rarely encountered glass steel pipes, steel pipes generally do not. PVC, most used, the cost is much lower than the glass steel

- Q: What qualifications do FRP pipes need to export to Australia?

- Need to comply with the local certification standards or international certification standards certification system

- Q: What are the main materials used for steel pipes?

- The grade of the material according to the general use of distinction: 1, clean air conditioning system with wind pipe: galvanized plate, stainless steel (disabled; glass steel, composite dust pollution may be used in the wind pipe with 2), the central air conditioning system: galvanized plate, color steel insulation board; (can use glass steel, the composite wind pipe) in 3, the environmental control system: galvanized steel plate, stainless steel; (can use plastic, glass steel, composite materials) duct 4, industrial ventilation system: steel plate, galvanized plate; (can use plastic, glass steel, composite materials) Note: can be divided into two kinds of organic and inorganic glass steel duct, according to the design specification has disabled organic material fire safety requirements; air duct 5, special occasions: glue cloth hairdryer, mine plastic mine ventilation pipe; (flame retardant and anti-static characteristics of mine safety requirements)

- Q: Which is better, PVC pipe and GRP pipe?!

- To see the composition of your gas, fiberglass can be chosen according to the requirements of different resins for corrosion protection, and PVC for some gases are not corrosion-resistant,

- Q: How is FRP ventilation pipe made?

- Coating moldingOn the surface of the mold, a transparent glass paper is fixed on the surface of the bread. When it is fixed, it is coated with a resin coating which has been adjusted. It should be even and not exposed. Then apply a layer of glass cloth and then coat with a resin coating. Each coated with a layer of resin is deposited a layer of glass cloth. The cloth lap to stagger and scraping, the outermost layer of ruibu glass surface should be coated with a layer of resin coating. After reaching the required thickness, and then deposited on the outer surface of the glass paper flatten the light pressure.

- Q: What are the advantages of glass fiber reinforced plastic sand pipe than HDPE pipe?

- Advantages of FRP pipes:1, insulation, acid, alkali and salt corrosion, antistatic, rust, aging is not easy, the service life of up to 50 years.2, non-magnetic, non electrical corrosion, waterproof performance, and can be used in humid environment or water for a long time without deterioration.3, high strength, is the same degree of the original PE pipe is more than 6 times, light weight, smooth wall, perforated cable when the friction coefficient is small, no cable operation.4, heat resistance, antifreeze, fire protection, fire retardant type. It can be used for a long time at -35 ~ 139 degrees celsius.5. The bending modulus is good, the impact resistance is strong, and it solves the defects of metal tube easy to decay and no distortion and elasticity.6, the cable across the bridge and across the river, the use of glass fiber reinforced plastic catheter is more economical and appropriate.7, construction and installation is very simple, no need to tie steel, pouring concrete.

- Q: Would like to ask about the plastic lined steel pipe, steel pipe, glass steel skeleton, the advantages and disadvantages of each ceramic pipe, to know a friend told, very grateful!

- FRP corrosion resistance, high strength (afraid of tanks), light quality, easy to install, socket or flange interface, the price is more expensive than cement

- Q: Who knows, how is the glass reinforced septic tank connected with the municipal pipe?

- If a glass fiber reinforced plastic outlet pipe is reserved, a new sewage inspection well is installed at the pipe end, and then a sewage pipe is installed to connect the reserved manhole of the municipal sewage pipe.

Send your message to us

High Quality Composite Fiber Glass FRP Pipe Rod

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords