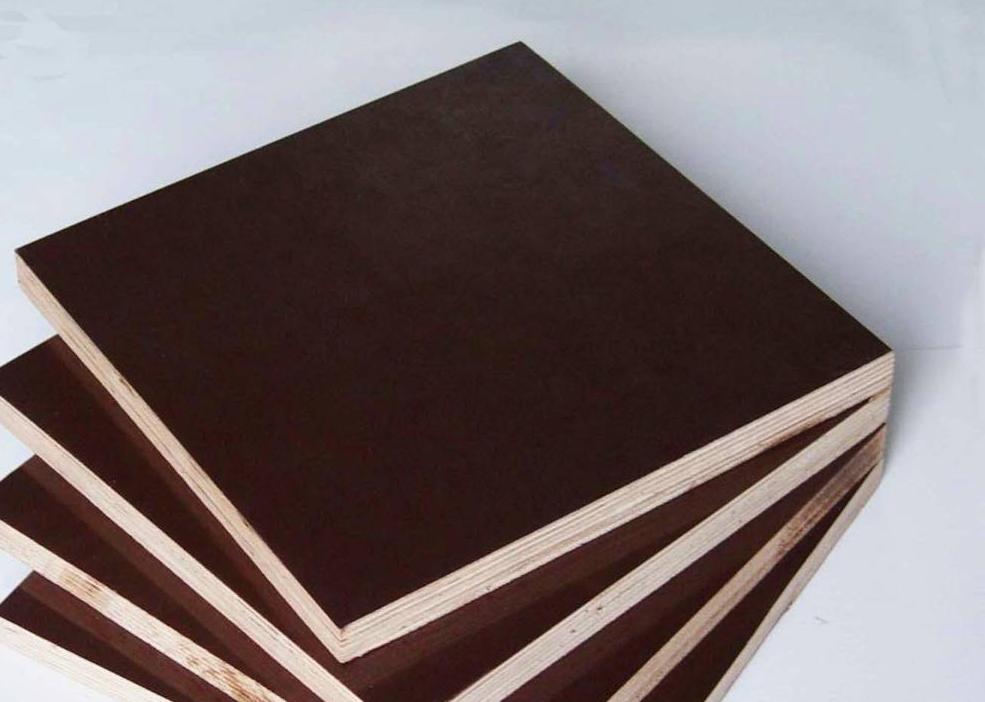

Pressure Treated Combi Core Marine Plywood / Film Faced Plywood / Construction Materials

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specification:

Item:film faced plywood

Size:1220x2440mm

Thickness:9mm,12mm,15mm,18mm,20mm,25mm,customer's thickness is available

Color:Brown,Black,Red

Description:

Name | combi core building film faced plywood material | ||

Brand | PLAD | ||

Using times | More than 30 times | ||

Core | Poplar , Eucalyptus , Birch , Hardwood , Combi core | ||

Glue | WBP Phenolic melamine MR | ||

Surface | Smooth plastic antislip plastic | ||

Adhesive of PP film | Hot melt pp plastic nails | ||

Edges | Seal(can print logo in edges) | ||

Size | 1830x915mm 2440x1220mm 2500x1250mm | ||

Thickness | 9mm 12mm 15mm 18mm 19mm 20mm 21mm | ||

Thickness tolerance | +/-0.5mm | ||

Moisture | <8%-12%< span=""> | ||

Color | Green,black | Patent | National Invention Patent: 2012 1 0354370.6 |

Factory | YES | Utility Model Patent: 2011 2 0348383 .3 | |

Hot press | two times | Appearance Design Patent: 2013 3 0483215.X | |

Advantages | |||

1.No need of release agent,easy to demoulding. | |||

2.Light in weight,easy to use,can be cutted to any size. | |||

3.Firmly surface,Perfect concrete molding. | |||

4.The core will never crack and deformed.Can be used more than 30 times. | |||

Features:

1. Transference to concrete is set up very easily, so good for construction work. (There is no need for any transference preparation.)

2. After installation of concrete, the surface looks like a mirror. (the cement does not stick.)

3. You are able to use film faced plywood until the plywood itself is damaged. (Strong with nailing and knifing)

4. Environmentally friendly. (Even after incineration, there is no hazardous substance.)

5. It can be used for a long time, and for the initial price paid for the material, you will feel its worth over time

FAQ:

1, What is your MOQ?

Our MOQ is usually 20CBM

2, What is your delievery time?

The time of delivery is winthin 15days after we receive the deposit.

3, What is the shipping port?

We ship the goods via Lianyungang port.

4, What is your payment terms?

We accept 30% T/T in advance,70% in the period of shipment. Or L/C at sight.

5, What is your main products?

Our main products are film faced plywood, commercial plywood, MDF.

6, How about the samples?

We could send you the samples but the freight are charged. After the order is confirmed, we would pay back the express fee. Please be rest assured of the

- Q: National standards for decorative veneer veneer plywood performance requirements

- The standard on the decorative veneer veneer plywood in the appearance of quality, processing accuracy, physical and mechanical properties of the three aspects of the indicators.

- Q: Commonly used plywood, pallets and so on

- so it will not crack, but it can not be called solid wood, and now the market has solid wood particle board, MDF, particleboard and other components of the plate Is wood chips, sawdust,

- Q: Multilayer board and plywood difference

- A group of boards are usually made of mutually adjacent panels in the direction of the adjacent layers.

- Q: The density of the plywood is greater than that of the same kind of wood

- The greater the unit pressure when gluing, the greater the density of the plywood. As the wood at high temperature easy to produce plastic deformation, hot glue gluing than the compression of the compression rate is greater.

- Q: Distinguish between multilayer boards and plywood

- With the veneer after the wood by the direction of the criss-cross the composition of the slab, heated or not heated under the conditions of suppression.

- Q: Material for the plywood defects which

- spotted flecks streaks system wood fungus invasion of wood early formation, often see brown. Tan or purple stains.

- Q: What kind of glue is today's plywood?

- if you want to make outdoor use of wood products, you can use E1 grade (or even E0 level) phenolic glue.

- Q: Plywood quality requirements include appearance level, size, physical and mechanical properties of the three elements.

- Appearance level, size, physical and mechanical properties of the three tests are qualified to determine the product is a qualified product, or judged to be unqualified. P

- Q: Poisoning diagnosis and grading standards

- clinical manifestations of disturbance of consciousness, and exclude other diseases caused by changes in central nervous system function before the diagnosis of acute benzene poisoning; according to the degree of disturbance of consciousness, Severe secondary.

- Q: The usual length and width specifications are:

- The main tree species are: camphor, willow, poplar, eucalyptus and so on. The main origin of plywood: Indonesia and Malaysia.

Send your message to us

Pressure Treated Combi Core Marine Plywood / Film Faced Plywood / Construction Materials

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords