Sheet Glass 2.0mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

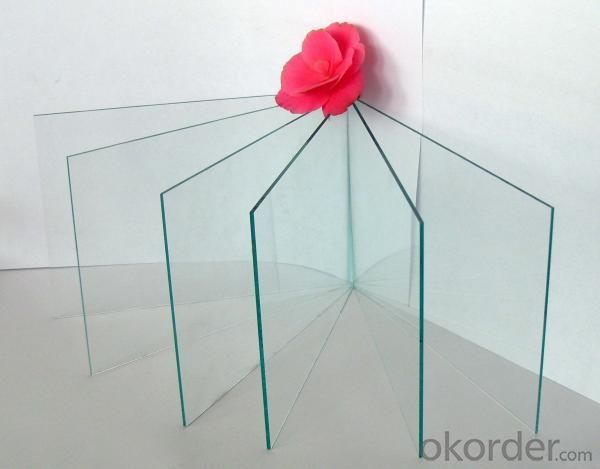

Sheet Glass is a kind of ultra thin glass, whose thickness is less than 3mm.

Features:

1. good planeness

2. little tolerance on thickness

3. excellent quality

Specifications:

Thickness: 2mm

Size:

500*700mm; 600*900mm

610*914mm; 1220*914mm

1830*1220mm; 1830*2440mm

Customized size

Applications:

Sheet Glass is mainly used in picture frames, mirrors, windows, building, arts and crafts, instruments, etc.

- Q: How can glass frosting be formulated? What raw materials do you use?

- Preparation of water-based environment-friendly frosting liquid, according to the A Group 8, B group of 2, the proportion with 5 copies of the preparation of tap water (25kg water frosting powder add 12.5Kg, preparation of tap water) according to the proportion of A group and B group into a plastic bucket, then according to the proportion of entering tap water (if prepared with 80 degrees above water could shorten the curing time more than half) with plastic (or bamboo sticks) stir until evenly, liquid will be prepared to cover seal, so that in the outdoor temperature under natural curing for 24 hours. The newly formulated frosting is thicker and the temperature drops. After ripening, the viscosity and temperature of the liquid can be restored to normal. When the preparation amount is large or the weather is cold, the aging time should be prolonged appropriately.

- Q: How is glass made? What are the main ingredients?

- Preparation of batch. According to the product, the composition of the mixture is slightly different. For example, ordinary float glass batch (calculated in accordance with 1 weight boxes of 50 kilograms), need to consume 33.55 kg of quartz sand, limestone, dolomite, 2.96 kg 8.57 kg 11.39 kg of soda, Glauber's salt 0.55 kg, 3.45 kg, 0.03 kg of feldspar powder etc..

- Q: List and characteristics of chimney glass flake cement

- Due to the relative stretching coefficient of the steel, cement and other material and substrate, so in the case of heat shock resin layer easily cracking and shedding, and glass flake could commission a heat stable layer, which can prevent the substrate cracking and spalling.

- Q: Renovation of the house to buy bricks when how to see the quality of good or bad? What kind of good?

- According to the degree of finish is divided into yaguangyoumianzhuan and light glazed tiles. At present, the ground material with more matte glazed tiles.The tiles (or tiles) is the use of earth embryo (or earth embryo to add some ore powder) after high temperature and high pressure one-time firing, using the surface and bottom of embryo material basically identical (except for the special process such as tiles, tiles in the new fill glaze series). Vitreous tile belongs to all ceramic product. Its abrasion resistance and flexural strength are very high, the water absorption rate (tile water absorption rate is less than 1 per thousand). Before the tiles mainly used for flooring, tiles, as a wall material is mainly used for high-grade Gaestgiveriet Hotel, office space, but now, with the living standard and the improvement of consumption level, the home use tiles for the kitchen wall materials are more and more family.

- Q: How is glass made?

- Technological process:1, raw materials broken: the above raw materials broken into powder;2, weighing: according to the list of ingredients, called a certain amount of powder;3, will be called: the mixed powder mixing, stirring into a batch (colored glass and colorant);4, melting: the mixture into the glass furnace, melting at 1700 degrees into glass;5, forming: the glass liquid into a tin bath (float), pull machine (lattice method), rolling machine (rolling method, adding metal wire is wire glass), forming the flat glass;6, annealing: the molding of glass products into the annealing furnace annealing, balance the stress, to prevent self cracking.

- Q: How is glass made? I heard that sand is used, but what is the concrete principle?

- The main raw materials of flat glass are: silica sand (sandstone), sodium carbonate, feldspar, dolomite, limestone and mirabilite.

- Q: What is the difference between white float glass and ordinary float glass?

- The iron oxide content of ultra white float glass is low, so the raw materials (sand or sandstone) to low iron content, iron content can be the best sand control below 0.03%

- Q: Toughened glass and ordinary glass, process and raw materials what is the difference, a little more detailed, thank you

- Glass production process is: raw material crushing, screening, weighing, mixing, high temperature (1600 degrees) melting into glass, glass homogenization, cooling molding, cutting, annealing, cooling, inspection, packaging.The main raw materials are: quartz sand or sandstone, feldspar, soda ash, limestone, dolomite, etc., in addition to soda ash are ore raw materials, need to be broken into the appropriate size.

- Q: Consult the experts on injection molding. Injection of raw materials Riga glass material, OK?

- There are many kinds of glass fiber material, such as PP, PA, ABS, PC and so on, which can be used according to needAdd different amounts of glass fiber

- Q: The shell of glass steel electric cars will not be on the poor out of the glass Sizha?

- There are two kinds of molding process, high temperature molding (SMC molding) and room temperature molding (hand paste or vacuum assisted molding). SMC molded, there is no problem of glass fiber, hand paste or vacuum assisted molding. If it takes a long time, you will see the bare phenomenon of glass fiber. You can look at the back of his shell, and if you see the surface is not smooth, it should be hand shaped, usually if the car's output is very large, with SMC molding more. My humble opinion. I hope I can help you.

We were established in 1984. By issuing both A-shares and B-shares in Shenzhen Stock Exchange in 1992, we became one of the earliest listed companies in China with the total assets of nearly 15 billions , more than 20 subsidiaries and the staff of nearly 12000 people at present.

1. Manufacturer Overview

| Location | Shenzhen, China |

| Year Established | 1984 |

| Annual Output Value | |

| Main Markets | Mid East; Eastern Europe; North America |

| Company Certifications | ISO 9001:2008;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shenzhen, China |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | High; Average |

Send your message to us

Sheet Glass 2.0mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches