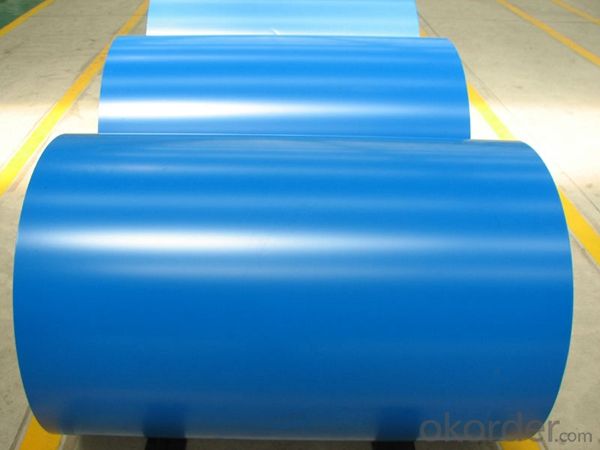

Color Coated Aluminum Pipes with Blue Aluminium Coils for ACP Top Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Blue Aluminium Coils for Color Coating ACP Top Coils

characteristics | Application |

1) Super peeling strength | 1) Building exterior curtain walls |

2) Excellent surface flatness and smoothness | 2) Decoration and renovation additions for old buildings |

3) Superior weather, corrosion, pollutant resistance | 3) Decoration of interior walls, ceilings, bathrooms, kitchens and balconies |

4) Even coating, various colors | 4) Shop door decorations |

5) Fireproof, excellent heat and sound insulation | 5) Advertisement board display platforms and signboards |

6) Superior impact resistance | 6) Wallboards and ceilings for tunnels |

7) Lightweight and easy to process | 7) Industrial materials, materials for vehicles and boats |

2. Application of Blue Aluminium Coils for Color Coating ACP Top Coils

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels, column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Blue Aluminium Coils for Color Coating ACP Top Coils

• Our goods quality is top, the surface is smooth, and every steel coil

• No Joint, No Bends, no spots, no roller marks.

• MTC will be provided with goods, third part inspection is acceptable, for example, SGS, BV. Etc

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

5. Image of Blue Aluminium Coils for Color Coating ACP Top Coils

6. Package and shipping of Blue Aluminium Coils for Color Coating ACP Top Coils

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: How do aluminum pipes handle vibration and shock loads?

- The remarkable ability of aluminum pipes to handle vibration and shock loads is widely recognized. This can be attributed mainly to their inherent characteristics and properties. Being a lightweight and highly ductile metal, aluminum possesses the unique capability to deform under stress without fracturing. This flexibility allows aluminum pipes to effectively absorb and dissipate vibrations and shocks, preventing their transmission to other components of the system. Furthermore, aluminum boasts a high strength-to-weight ratio, endowing it with great durability and resilience. Consequently, aluminum pipes can withstand significant impact forces and sudden shocks without deforming or failing. This exceptional strength makes aluminum pipes an ideal choice for applications in industries such as automotive and aerospace, where vibration and shock loads are anticipated. Notably, aluminum exhibits excellent resistance to corrosion, rendering it suitable for usage in diverse environments. Corrosion can weaken pipes, making them more susceptible to failure under vibration and shock loads. However, the corrosion resistance properties of aluminum ensure the structural integrity of the pipes remains intact over extended periods, enabling them to withstand such loads. In summary, aluminum pipes possess the necessary attributes to handle vibration and shock loads effectively. Their lightweight nature, ductility, high strength-to-weight ratio, and corrosion resistance make them a dependable choice for applications where these loads are a concern. As a result, aluminum pipes offer durability and longevity to the systems in which they are employed.

- Q: Air conditioning brands on the market, such as GREE, Midea, chigo... What uses copper tubes and what uses aluminium tubes?.1. Experts try to say more about the brand.2. Which is better, copper or aluminum pipe?Sincerely ask, do not copy.

- At present, the domestic market, large manufacturers of air conditioners, heat exchangers are basically copper. Such as Midea, GREE, Haier. Imported Daikin, LG, Panasonic and so on.Brass is mature in technology, to meet the performance requirements is no substitute for aluminum, aluminum has a gap in corrosion resistance, hardness and so on, when very high copper prices in 2008 had proposed to replace copper with aluminum, some small manufacturers have done. But regular manufacturers do not use aluminum tube

- Q: What ion is corrosive to the aluminum tube?

- Too much, mainly is the strong oxidizing ion such as hydrogen ion, iron ion, nitrate ion, permanganate ion and so on

- Q: How can the refrigerator aluminum pipe leak?

- 2. Replace and repair evaporator. All need to be dug out from the freezing room, replaced, repaired, restored, and filled with a foaming agent, and then added refrigerant, the price is not expensive.

- Q: Which friend has the national standard about seamless copper tube and aluminium tube, some help to send, very grateful, urgent!

- National standard for seamless aluminium tubesnominal outside diameterOrdinary (+)High precision (+)Any outside diameter a and nominalAllowable deviation of outside diameterAllowable deviation of average outside diameter B and nominal outer diameterAny outside diameter a and nominalAllowable deviation of outside diameterAllowable deviation of average outside diameter B and nominal outer diameterAnnealing tube5083 CQuenchOtherAll tubesAnnealing tubeQuench tubeOtherAll tubes> 120 to 150Two point two eightZero point six threeZero point seven sevenZero point three eightZero point three eightOne point five zeroZero point five zeroZero point two fiveZero point two five> 150 to 180Three point four fourZero point nine fiveOne point one fourZero point five sevenZero point five sevenTwo point two fiveZero point seven sixZero point three eightZero point three eight> 180 to 220Four point five eightOne point two fiveOne point five threeZero point seven sevenZero point seven sevenThreeOneZero point five zeroZero point five zeroA any outer diameter refers to the outside diameter measured at the point at the pipe section.The mean od of B refers to the average value obtained by measuring the total diameter of two arbitrary angles at the cross section of the pipe.When the C 5083 alloy tube is annealed, the deviation is performed by the annealing tube.[amendment to the national standard 2012-06-14 14:45] seamless copper tube

- Q: I have a diameter of 10mm, wall thickness of 1mm aluminum alloy hollow round tube, need to bend into diameter 180mm circle, how to process better, will not rebound, the position of the arc smooth and beautiful!Which master can help? Times of gratitude!

- Rounding machine ah ~ no words can help me you do! I have several sets of rolling machine! The pipe is well made! Your satisfaction is guaranteed.

- Q: What are the advantages and disadvantages of steel tubes, aluminium tubes and stainless steel pipes?

- You should first find out the material brand, and then find manufacturers to test specimens to do material reports, and then consult the materials manual or the corresponding national standards to control whether it meets the requirements of the standard!

- Q: My company plans to rust aluminum 15 Phi Phi 8 hit a row of holes, then Phi 8 Phi 15 in aluminum pipe welding, welding oxyacetylene welding using plan copper welding current, using nitrogen or nitrogen and hydrogen in welding. As a result, many welding leaks and air holes were found in aluminum tube welding, and the welding success rate was low. How can I improve it?

- Need efficient, buy brazing furnace. Brazing in furnace.

- Q: Can aluminum pipes be used for conveyor rollers?

- Indeed, aluminum pipes have the capability to serve as conveyor rollers. Aluminum, being a material that is both lightweight and durable, presents numerous benefits for conveyor systems. Its resistance to corrosion renders it appropriate for usage in a range of environments, including those with exposure to moisture or chemicals. Moreover, aluminum pipes possess a notable strength-to-weight ratio, enabling them to endure hefty loads while remaining light in weight. Furthermore, aluminum proves to be effortless to manipulate and can be tailored to fulfill specific requirements such as size, shape, and length. Consequently, aluminum pipes emerge as a fitting selection for conveyor rollers, providing a dependable and efficient solution for handling materials.

- Q: What are the different diameters available for aluminum pipes?

- The diameters available for aluminum pipes can vary depending on the manufacturer and specific requirements. However, aluminum pipes commonly come in a range of diameters starting from as small as 0.25 inches (6.35 mm) and going up to larger sizes such as 12 inches (304.8 mm) or even more. The specific diameter options available may also depend on the intended use of the aluminum pipes, as different industries and applications may require specific sizes. It is always best to consult with the manufacturer or supplier to determine the exact range of diameters available for aluminum pipes that meet your specific needs.

Send your message to us

Color Coated Aluminum Pipes with Blue Aluminium Coils for ACP Top Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords