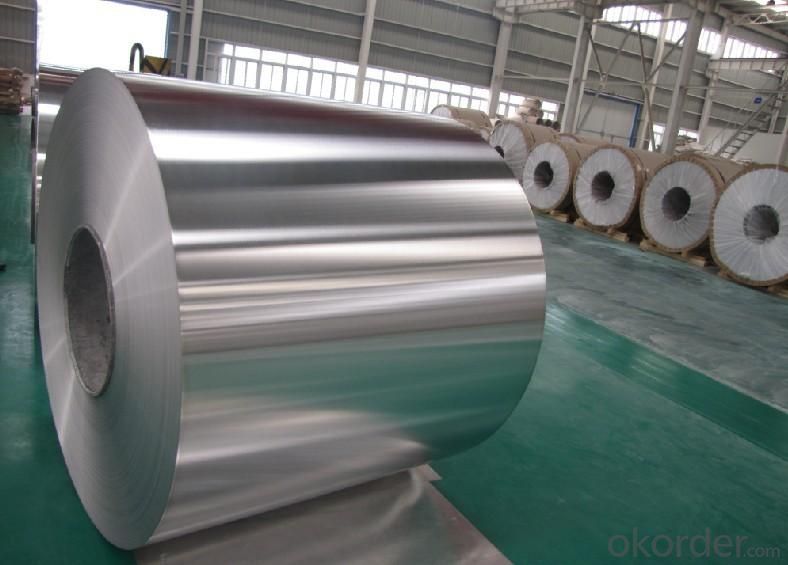

Wholesale Aluminium Ceiling Panels - Color Coated Aluminum Coil AA5006 Aluminum Alloy

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

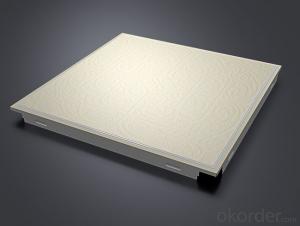

Color Coated Aluminum Coil AA5006 Aluminum Alloy

1. Grade

| Series: | 1100 etc. |

| Series: | 3003 3004 3005 etc. |

| Series: | 5006, 5052 |

| Series: | 8011 etc. |

2. Thickness

| Plate Thickness | 0.1mm, 0.12mm,0.15mm,0.20mm,0.25mm,0.28mm,0.3mm,0.35mm,0.38mm, 0.4mm,0.5mm, 0.53mm, 0.58mm,0.68mm,0.7omm,0.73mm,0.75mm, 0.90mm, 1mm, 1.2mm |

| Coil Thickness | 0.1mm, 0.12mm,0.15mm,0.20mm,0.25mm,0.28mm,0.3mm,0.35mm,0.38mm, 0.4mm,0.5mm, 0.53mm, 0.58mm,0.68mm,0.7omm,0.73mm,0.75mm, 0.90mm, 1mm, 1.2mm |

3. Description

Alloy | AA1100, 3003, 3004, 3105, 5006, 5052, 8011, etc , etc. |

Temper | H16, H18, H24, H26, H28 |

Thickness | From 0.1mm to 1.2mm |

Width | Standard width:1240mm, 1270MM |

Special width:1000mm, 1200mm, 1240mm, 1270mm, 1520mm, 1620mm | |

Diameter | Standard dia:1200mm |

Interior dia: 150mm,405mm, 500mm, 505mm, 510mm | |

outer diameter: 1200mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating thickness | PE:>=16 micron , PVDF:>=25 micron |

Protective film | As per customer’s request |

Coating paint | PVDF, PE(Polyester), epoxy, polyamide, polyurethane |

Color | Soid, metallic, high gloss,stone,timber,brush,mirror,sparkling, RAL or by customer requirements. |

Weight | As per customer’s request |

| Surface | Embossed, mill finish, coated |

| Gloss | 10-100% |

| Coating Hardness (pencil resistance) | More than 2h |

| Coating adhesion | 1J |

| Impact Resistance | No peeling or cracking(50 kg/cm) |

| Application | ACP,wall cladding,facades,roofs and canopies,ceilings,signboards,blind window,display platforms,electrical panels,etc |

| Coating Thickness | PE coating:more than 16 micron |

| PVDF coating:more than 25micron |

4. FAQ

Q: Can you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons

Q: What are your payment terms?

A: We accept L/C, D/A, D/P, T/T, West Union, etc

- Q: How about the quality of the ceiling

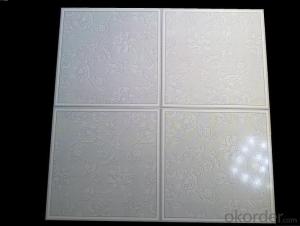

- Aluminum cords board ceiling quality is good, buy aluminum slab ceiling, look at the aluminum, film, back cover, from these three aspects to test the quality of aluminum gusset, AIA integrated ceiling quality in this area. First, check the aluminum material, because the average consumer is difficult to see the aluminum material, it is recommended that consumers look at the hardness of the buckle plate, and then check the paint is smooth, no burr, with or without color. Second, look at the film, the consumer can pull the edge of the board, if the phenomenon occurs from the film that is, this film is not close with the buckle plate; again look back cover (buckle back), which is a lot of consumers Ignore a part. Back cover generally have to be anti-corrosion treatment, hand to pull, if the back cover can pull out the description of its material is not good; and the general manufacturers will be in the back of the inkjet manufacturers logo and production date, through the presence of these words, Consumers can also identify the product is good or bad. If there are, that it is a regular factory of the machine production, is different from the small workshop, the quality is relatively guaranteed.

- Q: Integrated ceiling aluminum slab plate production process?

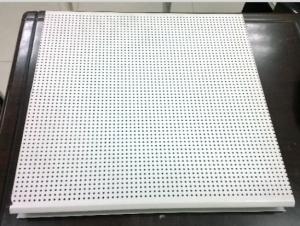

- Integrated ceiling aluminum plate production process: Kouban production is a very rigorous process, every link is very strict, so that it can produce qualified aluminum slab products. The first step is the aluminum plate surface treatment, such as film, roller coating, spraying, wood transfer and so on. The second part, aluminum plate scissors. It means that the aluminum roll cut into the required size. Such as 300 * 300 specifications. The third part, press molding. Using different aluminum buckle plate abrasive extrusion. There are two parts: strip and square. Fourth, the packaging. Carton and plastic foam packaging out of the library.

- Q: What is the characteristic of the ceiling plate?

- To achieve a beautiful and beautiful construction and easy maintenance of the perfect combination of the factory to complete the production, the construction of fast quality and stability, and ultimately can be fully recycled recycling, green materials.

- Q: What is the brushed aluminum plate

- The following is a detailed description of the surface treatment of the plate: 1, coating process: directly on the aluminum substrate on a high temperature die-casting thickness of 18-25C PVC film, the disadvantage is the surface easy to change color. 2, roller coating process: the surface is coated with a layer of polymer coatings, the advantage is durable and difficult to change color. 3, roller screen printing: roller on the basis of the plate and a screen printing, the effect is to make a single roller has become rich color. (Also known as hot infiltration printing): and silk screen is the same as in the roller coating on the basis of printing, but the thermal penetration of the ink through the high temperature method of sublimation to penetrate into the roller coating inside , The face is touched is not feel rugged, and thus feel that this is the difference between the screen printing, thermal penetration printing is a digital way, the color can be composed of N kinds. But silk screen can only be composed of one by one color. 4, matte process: in the aluminum plate on the top of the drawing, and then after the process of manufacturing varnish. Currently on the market the most common of a plate.

- Q: How to distinguish between the aluminum plate is good or bad?

- The corners of the gusset The simplest is to do an experiment, that four pieces of chuck together into a large square to see if the middle of the seam is not very close fit.

- Q: Kitchen bathroom aluminum plate to the top of the original distance is generally how much?

- Depends on the ground to stay high, the above only how much, the general kitchen from the ground to the top is 2 meters 4 or so, the bathroom to be shorter, space, small winter bath is not cold, and sliding doors do

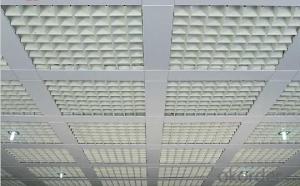

- Q: What are the precautions and corresponding regulations in the construction of aluminum slabs?

- Aluminum slab plate ceiling construction Note: From the beginning to the end of the ceiling construction, we should pay attention to protect the roof of the various pipelines are not damaged. During the construction process, all kinds of keel and boom are forbidden to be fixed on the ventilation ducts and other equipment parts, only on the roof board. In the handling, storage, use of materials in the process, to prevent material deformation, moisture and rust. Attention to protect the windows and doors installed is not damaged. Light steel skeleton can not be stampede; other types of hanging parts shall not be hanging on the light steel skeleton. Before covering the cover plate, make sure that the pipe in the ceiling has been inspected and that the mask plate is installed after acceptance.

- Q: Aluminum buckle board a side of the edge of how fixed

- Aluminum-plastic plate Construction process: keel layout and elastic line → installation and leveling keel → installation of aluminum-plastic plate → trim sealing. 1), the elastic line: to determine the elevation control line and keel layout line, if the ceiling has a variable height, the corresponding part of the variable section should be determined, and then along the elevation line fixed angle aluminum. 2), to determine the keel position line: According to the size of aluminum-plastic panels and ceiling Aluminum plate is made of aluminum alloy plate, through the open material, shear angle, molded, aluminum plate surface using a variety of different coating processing to get a variety of aluminum plate products, aluminum slab plate, the most important two Type, one is home improvement integrated Lvkou Ban, the other is the engineering Lvkou Ban, home-made aluminum slab board mainly to roll and frost the main series of two, with the development of home improvement integrated aluminum plate has been Variety of different processing technology are used to them, such as thermal transfer, glazed, ink printing, mirror, 3D and so on series is the most popular in recent years, home improvement integrated aluminum slab plate, home improvement integrated aluminum plate is Board surface fancy, service life, board advantage and so on to obtain market recognition, engineering aluminum slab board is commonly used roller coating, powder coating, film, scrub and other surface coating, the surface is relatively simple, the color is solid , Of which milky white is the most expensive to use aluminum slab plate, engineering aluminum plate to buy the most important depends on the coating, coating color protection is the primary consideration, the coating to maximize the life to ensure that the owners interest.

- Q: Aluminum buckle ceiling ceiling how to do

- This depends on the type of ceiling board to choose the appropriate solution. Specifically, it is divided into the following two cases: 1, the ceiling of the board for the square board (the general specifications in the 30 cm or so square), first remove the ceiling next to a square plate, using a wallpaper knife blade into the ceiling lamp and the surrounding square between the gap of a certain size And then the blade will pry the square around the ceiling lamp and then take the board from the side of the side where the board has just been leveraged. After the ceiling of the connection to the wire to be replaced after the replacement of ceiling lights. To be finished after the lamp, and then re-install the square board can be removed just. 2, the ceiling of the board for the board (that is, long strip), to remove the ceiling lamp, you need to ceiling lights on both sides of the strip on both sides of the buckle first removed, and then take the board and change the lights.

- Q: How to deal with the aluminum slab board ceiling installation Yuba after the resonance

- If installed after the whole top of the vibration will be in Yuba and keel contact place pad cloth. The main keel is best not to use light steel keel

Send your message to us

Wholesale Aluminium Ceiling Panels - Color Coated Aluminum Coil AA5006 Aluminum Alloy

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords