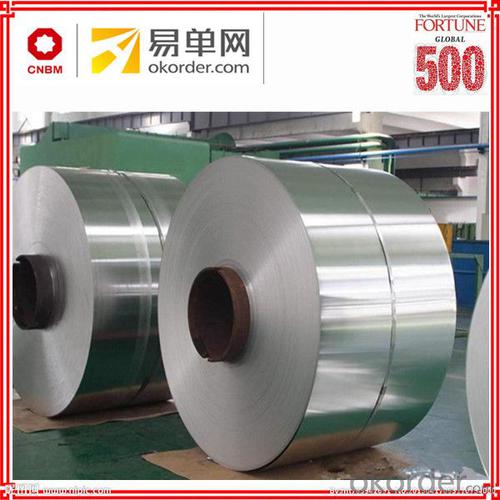

Cold rolled steel sheet in coil wholesale alibaba

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 59450 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

These cold rolled steel coil/sheet grades have excellent formability, which facilitates cold forming operations, and are ideal for deep drawing. Our range of steels for cold forming offer excellent forming performance, due to the low scattering of their chemical composition and their mechanical properties, which guarantees processing consistency.

Standard and Grade :

Cold rolled steel coils | ||||

JIS G3141-2005 | EN10130-2006 | ASTM A1008-12a | ||

Commercial quality | SPCC | DC01 | CS Type A/B/C | |

Drawing quality | SPCD | DC03 | DS Type A/B | |

Deep drawing quality | SPCE SPCF(non aging) | DC04 | DDS | |

Extra deep drawing quality | SPCG(non aging) | DC05/06 | EDDS | |

Application :

Automobile Industry, White Goods, Home Applicances, Oil & Air filters, semi product for coating with enamel or zinc,

construction & building sector, air-conditioning, furniture, radiators, tubes, profiles, mechanical construction, shelving,

containers, drums

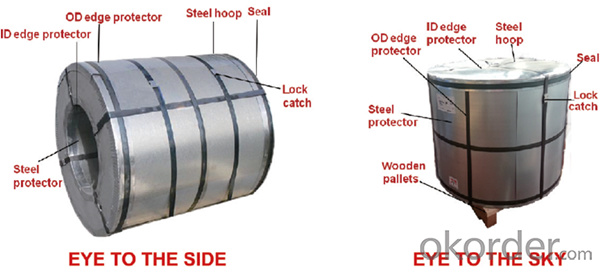

Packing:

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

FAQ:

1. Can you offer OEM to me? What about MOQ?

Of course, we are a professional with OEM manufacturer for 9 years. the MOQ can be 50 ton/ order..

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

4.How Can I Get Some Sample?

We are honored to offer you free sample, but courier charges will be on your side.

- Q: The highest quality i have seen is 9260 and i want to know if there is a higher quality steel.

- Types of steel are one issue. But the quality of steel no matter what type is even more important. The only way to be sure that you are getting a good blade is to buy from someone that already has a reputation for producing great blades. Stop the questions about who thinks what type of steel is best and investigate the steel blades offered by companies like Bugei Trading company. they have good blades. Opinions vary, but Bugei has proven that they make good swords. That is all that is needed to be known. Any questions you have are best directed to them, not here.

- Q: did bible stated that steel is coming from outer space. i mean meteor rocks that enter our earth sistem contains the minerals iron.

- Steel is not elemental, if that's what you mean. It's a metal alloy, a combination of mostly iron and some carbon. Iron and carbon both occur naturally on the Earth, but you have to melt them together to make steel.

- Q: I looking at replacing a few of the panels on my car with either Carbon Fiber or High Tensile Steel to shave off some weight and increase mpg and take some time off my quarter mile. Which is better: Carbon Fiber or High Tensile Steel?

- In terms of strength/weight ratio then carbon fiber is excellent. However in terms of strength/cost then steels is better. With strength/weight then you save money in the long run (less fuel usage) but with strength/cost ratio you save money immediately when the car is made. So it's a complex tradeoff that has to do with your time-value of money.

- Q: What are the different types of packaging for steel coils?

- The different types of packaging for steel coils typically include wooden crates, steel frames, and plastic wrapping. These packaging materials are used to provide protection and secure the steel coils during transportation and storage.

- Q: How are steel coils used in the production of infrastructure materials?

- Steel coils are commonly used in the production of infrastructure materials due to their strength and versatility. These coils are often transformed into various forms such as beams, plates, or pipes, which are then used in the construction of bridges, buildings, roads, and other vital infrastructure. The malleability and durability of steel make it an ideal material for withstanding heavy loads and harsh environmental conditions, ensuring the longevity and stability of the infrastructure.

- Q: How are steel coils used in the production of household goods?

- Steel coils are an essential component in the production of various household goods. These coils are typically made from high-quality steel and are manufactured to specific dimensions and thicknesses to meet the requirements of different products. One of the primary uses of steel coils in household goods production is in the manufacturing of appliances such as refrigerators, washing machines, and dishwashers. The coils are used to create the body and framework of these appliances, providing strength, durability, and stability. Additionally, steel coils are often used in the production of smaller household appliances like toasters, blenders, and coffee makers. Furthermore, steel coils are also used in the production of furniture, particularly in the manufacturing of metal frames for chairs, tables, and cabinets. These coils provide the necessary support and structural integrity to the furniture, ensuring long-lasting durability. Another significant application of steel coils in household goods production is in the production of shelving units and storage solutions. Steel coils can be shaped and formed to create sturdy shelves and racks that can hold heavy items and withstand regular use. These shelves are commonly used in kitchens, garages, and storage rooms to organize and store various household items. In summary, steel coils play a crucial role in the production of household goods. They are used to create the framework, structure, and support for appliances, furniture, and storage solutions. Their strength, durability, and versatility make them an ideal material for manufacturing a wide range of household products that are designed to withstand everyday use.

- Q: What are the common coil lengths available for steel coils?

- The common coil lengths available for steel coils vary, but typically range from 5,000 to 15,000 feet.

- Q: How are steel coils tested for compliance with industry standards?

- Steel coils are tested for compliance with industry standards through a series of rigorous quality control measures. These tests are conducted to ensure that the coils meet the necessary specifications and are suitable for use in various applications. One of the primary tests performed on steel coils is the dimensional inspection. This involves measuring the thickness, width, and length of the coils to ensure they meet the specified tolerances. Any deviations from the required dimensions can indicate a manufacturing defect or potential issues during fabrication. Another critical test is the visual inspection, where trained inspectors carefully examine the coils for any surface defects such as scratches, dents, or cracks. These defects can affect the performance and durability of the steel coils, making it essential to identify and rectify them before they are supplied to customers. Furthermore, mechanical properties testing is conducted to assess the strength, elasticity, and toughness of the steel coils. This includes tests like tensile strength, yield strength, and elongation measurements. These tests help determine the suitability of the coils for specific applications and ensure they meet the required performance standards. Additionally, chemical composition analysis is performed to verify the elemental composition of the steel coils. This analysis is crucial as it ensures that the steel meets the required chemical requirements, including the presence of specific alloying elements. Deviations in composition can impact the overall quality and performance of the coils. Corrosion resistance testing is also important, especially for coils used in environments with high humidity or exposure to corrosive substances. Coils are subjected to salt spray or humidity chambers to simulate real-world conditions and evaluate their resistance to corrosion. Lastly, various non-destructive testing techniques, such as ultrasonic testing and magnetic particle inspection, are used to detect internal defects or discontinuities in the steel coils. These tests help identify any hidden flaws that may compromise the structural integrity of the coils. Overall, steel coils undergo a comprehensive range of tests to ensure compliance with industry standards. By conducting these tests, manufacturers can guarantee that the coils meet the required specifications, providing customers with high-quality products that meet their specific needs.

- Q: What are the different methods of slitting edge trimming for steel coils?

- There are several methods of slitting edge trimming for steel coils, including rotary shear slitting, crush cutting, and laser cutting. Each method has its advantages and disadvantages, depending on factors such as the desired precision, speed, and the type of steel being processed.

- Q: What are the dimensions of steel coils used in the packaging industry?

- The dimensions of steel coils utilized in the packaging industry are subject to variation in accordance with the specific application and requirements. However, the customary dimensions for steel coils employed in packaging encompass a thickness ranging from 0.15 mm to 3 mm and a width spanning from 600 mm to 2000 mm. The internal diameter of the coil, referred to as the core, generally measures around 508 mm (20 inches); however, alternative sizes such as 610 mm (24 inches) or 762 mm (30 inches) may also be utilized. The outer diameter of the coil may fluctuate contingent upon the weight and size of the coil, yet it commonly falls between 1000 mm and 2000 mm. It is crucial to emphasize that these dimensions can be tailored to accommodate the specific requirements and preferences of the packaging industry.

Send your message to us

Cold rolled steel sheet in coil wholesale alibaba

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 59450 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords