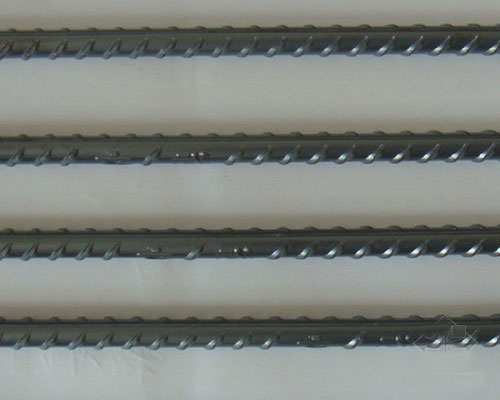

Cold Rolled Steel Rebar 10mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Usage and Applications of Hot Rolled Steel Rebar:

Deformed bar is widely used in buildings, bridges, roads and other engineering construction. Big to highways, railways, bridges, culverts, tunnels, public facilities such as flood control, dam, small to housing construction, beam, column, wall and the foundation of the plate, deformed bar is an integral structure material. With the development of world economy and the vigorous development of infrastructure construction, real estate, the demand for deformed bar will be larger and larger..

Packaging & Delivery of Hot Rolled Steel Rebar:

Packaging Detail: products are packed in bundle and then shipped by container or bulk vessel, deformed bar is usually naked strapping delivery, when storing, please pay attention to moisture proof. The performance of rust will produce adverse effect.

Each bundle weight: 2-3MT, or as required

Payment terms: TT payment in advance or Irrevocable LC at sight.

Trade terms :FOB, CFR, CIF

Label:to be specified by customer, generally, each bundle has 1-2 labels

Steel Rebar in stock

Cold Rolled Techniques

Yield Point: 545-565mpa

Deformed bar is widely used in buildings, bridges, roads and other engineering construction. Big to highways, railways, bridges, culverts, tunnels, public facilities such as flood control, dam, small to housing construction, beam, column, wall and the foundation of the plate, deformed bar is an integral structure material. With the development of world economy and the vigorous development of infrastructure construction, real estate, the demand for deformed bar will be larger and larger.

- Q: How do steel rebars contribute to the structural soundness of a building?

- The construction industry heavily relies on steel rebars to ensure the structural integrity of buildings. These reinforcing bars, commonly referred to as rebars, are composed of steel and embedded within concrete to provide additional strength and reinforcement. One of the main ways in which steel rebars contribute to a building's structural soundness is by bolstering its tensile strength. Concrete is excellent at handling compressive forces but lacks strength when it comes to tension. Buildings are subjected to various loads, including wind, earthquakes, and their own weight, which exert both compressive and tensile forces. By incorporating steel rebars into the concrete, the overall structure's tensile strength is significantly improved. This prevents the concrete from cracking or failing under tension, guaranteeing the stability and durability of the building over time. Additionally, steel rebars enhance a building's ductility, which refers to its ability to deform under stress without breaking. Concrete, being a brittle material, lacks ductility and tends to fail suddenly when subjected to excessive stress. With the inclusion of steel rebars, the concrete-reinforced structure gains the capacity to absorb and distribute energy, allowing it to undergo controlled deformations without abrupt failure. This increased ductility ensures that the building can withstand dynamic loads, such as those generated during an earthquake, and reduces the risk of catastrophic collapse. In addition to improving tensile strength and ductility, steel rebars also contribute to the overall stability and load-bearing capacity of a building. By evenly distributing the load across the structure, they help minimize the concentration of stress in specific areas, thus preventing potential weak points or failure spots. This distributed load-bearing capacity ensures that the building can support its intended weight and endure the forces acting upon it. Furthermore, steel rebars play a crucial role in extending the lifespan of a building by offering protection against corrosion. Steel is prone to rust when exposed to moisture and air, which can compromise its structural integrity. However, rebars are often coated with epoxy or other anti-corrosion materials to prevent rusting. This protective layer ensures that the steel remains intact and maintains its strength over time, further bolstering the structural soundness of the building. To summarize, steel rebars are essential components in guaranteeing the structural soundness of buildings. They enhance concrete's tensile strength, improve its ductility, increase load-bearing capacity, and safeguard against corrosion. By incorporating steel rebars, buildings can withstand various loads, resist cracking, and ensure long-term stability and durability.

- Q: Can steel rebars be used in seawater desalination plants?

- Steel rebars are indeed applicable in seawater desalination plants; however, careful consideration must be given to the potential impact of corrosion caused by the high salt concentration in seawater. To address this concern, several measures can be adopted. One popular approach involves employing corrosion-resistant alloys like stainless steel rebars or epoxy-coated rebars to shield against the corrosive effects of saltwater. Furthermore, regular maintenance and monitoring are essential for averting and detecting any corrosion-related problems. In conclusion, although steel rebars can be utilized in seawater desalination plants, it is imperative to incorporate corrosion protection strategies to ensure their durability and structural soundness.

- Q: What are the advantages of using high-strength steel rebars?

- Using high-strength steel rebars in construction projects brings forth several advantages. Firstly, compared to regular steel rebars, high-strength steel rebars exhibit a significantly higher yield strength. As a result, they can endure much greater tensile forces without deformation or breakage. This allows for the construction of resilient structures capable of handling heavy loads and forces, thus enhancing their durability and resistance to damage. Secondly, high-strength steel rebars possess a smaller diameter while still maintaining their strength, unlike regular steel rebars. This characteristic makes them suitable for use in limited-space areas or scenarios requiring a smaller concrete cover. Consequently, they prove particularly beneficial in projects with intricate designs or in regions prone to high seismic activity. Furthermore, high-strength steel rebars offer increased cost-efficiency. Due to their superior strength, fewer rebars are necessary in construction projects. As a result, material and labor costs are reduced. Additionally, the smaller diameter of high-strength steel rebars leads to a decreased requirement for concrete, further lowering expenses. Another advantage of high-strength steel rebars lies in their enhanced corrosion resistance. The increased strength of these rebars is often achieved by incorporating alloying elements such as chromium or nickel, which enhance their resistance to corrosion. Consequently, structures reinforced with high-strength steel rebars boast a longer lifespan and necessitate less maintenance over time. Lastly, the utilization of high-strength steel rebars facilitates the construction of lighter and more slender structures. Their superior strength-to-weight ratio permits the design of longer spans and taller buildings without compromising safety or structural integrity. Consequently, aesthetically pleasing structures are created, and architects and engineers enjoy greater flexibility in their designs. In conclusion, the advantages of employing high-strength steel rebars encompass increased strength, smaller diameter, cost-efficiency, enhanced corrosion resistance, and the ability to construct lighter and more slender structures. These benefits establish high-strength steel rebars as the preferred choice in various construction projects, ensuring durability, safety, and longevity.

- Q: What is the role of steel rebars in load-bearing structures?

- The role of steel rebars in load-bearing structures is to provide reinforcement and increase the overall strength and durability of the structure. Steel rebars are embedded within concrete to enhance its tensile strength, as concrete alone is weak in tension. By distributing and resisting the applied loads, rebars help prevent cracks and failures, ensuring the stability and longevity of the load-bearing structure.

- Q: What is the process of inspecting steel rebars on-site?

- The process of inspecting steel rebars on-site involves several steps. First, the inspector assesses the quality and condition of the rebars by visually examining them for any visible defects such as cracks, rust, or bending. Next, they measure the rebars' dimensions and compare them to the specifications provided by the engineer or project requirements. This ensures that the rebars are of the correct size and shape. The inspector also checks the rebars' placement and alignment within the concrete structure, making sure they are positioned correctly according to the design plans. Additionally, non-destructive testing methods like ultrasound or magnetic particle inspection may be used to detect any hidden defects or flaws in the rebars. The inspector then documents their findings and prepares a detailed report, highlighting any issues or deviations from the required standards. This inspection process helps ensure the strength, durability, and safety of the steel rebars used in construction projects.

- Q: What is the process of calculating the required quantity of steel rebars for a project?

- The process of calculating the required quantity of steel rebars for a project involves several steps. First, the engineer or designer identifies the structural elements that require reinforcement, such as beams, columns, or slabs. Next, they determine the design requirements, including the desired strength, size, and spacing of the rebars. This is typically done by referring to the project's structural drawings, codes, and specifications. Once the design requirements are known, the engineer uses mathematical formulas and calculations to determine the quantity of rebars needed. These calculations consider factors such as the dimensions of the structural elements, the load-bearing capacity required, and the specific steel reinforcement design. The engineer then takes into account any additional factors that may affect the quantity of rebars required, such as laps, overlaps, and wastage. They may also consider the practicality and availability of standard bar lengths to minimize cutting and wastage. Finally, the engineer prepares a detailed bill of quantities, which specifies the quantity, size, and type of rebars required for each structural element. This information is crucial for procurement and construction purposes, ensuring that the right amount of steel reinforcement is available for the project.

- Q: What are the different types of steel rebars used in elevated highways?

- The different types of steel rebars used in elevated highways include carbon steel rebars, epoxy-coated rebars, galvanized rebars, and stainless steel rebars.

- Q: Can steel rebars be used in structures with long spans?

- Long-span structures can utilize steel rebars, which are frequently employed as reinforcement in concrete structures to enhance strength and stability. By effectively distributing tensile forces, steel rebars play a crucial role in averting cracks or failure in the concrete. In the case of long-span structures like bridges, high-rise buildings, or large industrial structures, it is common practice to reinforce concrete beams, slabs, and columns with steel rebars. This practice guarantees the structural integrity and stability of the building or structure, even when facing heavy loads or spanning lengthy distances. Thanks to their high tensile strength and resistance to corrosion, steel rebars are ideal for long-span structures, where durability and reliability are paramount.

- Q: Are steel rebars suitable for use in high-rise buildings?

- Yes, steel rebars are suitable for use in high-rise buildings. Steel rebars provide excellent strength, durability, and flexibility, making them ideal for reinforcing concrete structures in high-rise buildings. Their ability to resist tensile forces and bond with concrete ensures the structural integrity and stability required in tall buildings.

- Q: Can steel rebars be used in architectural or decorative concrete applications?

- Yes, steel rebars can be used in architectural or decorative concrete applications. They provide structural reinforcement and enhance the overall strength and durability of the concrete. Additionally, when properly designed and installed, steel rebars can be concealed or incorporated into the design, making them suitable for various aesthetic purposes in architectural or decorative concrete projects.

Send your message to us

Cold Rolled Steel Rebar 10mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords